Main chain donor-side chain receptor type conjugated polymer as well as preparation and application thereof

A conjugated polymer and donor technology, used in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problems of low device efficiency and difficult to form nano-phase separation, so as to improve device efficiency and enhance nano-phase separation. effect of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The representative synthetic route of polymer of the present invention sees Figure 6 ~ Figure 7 .

[0037] (1) Monomers M1 and M2 are synthesized according to the method disclosed in the literature [Journal of Materials Chemistry A, 2014, 2(23): 8773-8781.].

[0038] (2) Monomer M3 was synthesized according to the method disclosed in the literature [Chemistry of Materials, 2014, 26(11): 3495-3501.].

[0039] (3) Monomer M4 was synthesized according to the method disclosed in the literature [Energy & Environmental Science, 2017, 10(5):1243-1251.].

[0040] (4) Monomer M5 was synthesized according to the method disclosed in the literature [Advanced Materials, 2016, 28(44): 9811-9818.].

[0041] (5) Synthesis of polymers P1, P2, P3:

[0042] P1: Add monomer M1 (0.5mmol) and monomer M3 (0.5mmol) into a 25mL two-necked flask, pass through nitrogen protection, and add 8mL of toluene. Add 5mg Pd(PPh 3 ) 4 , After reacting at 95°C for 12h, the polymer was precipitated wi...

Embodiment 2

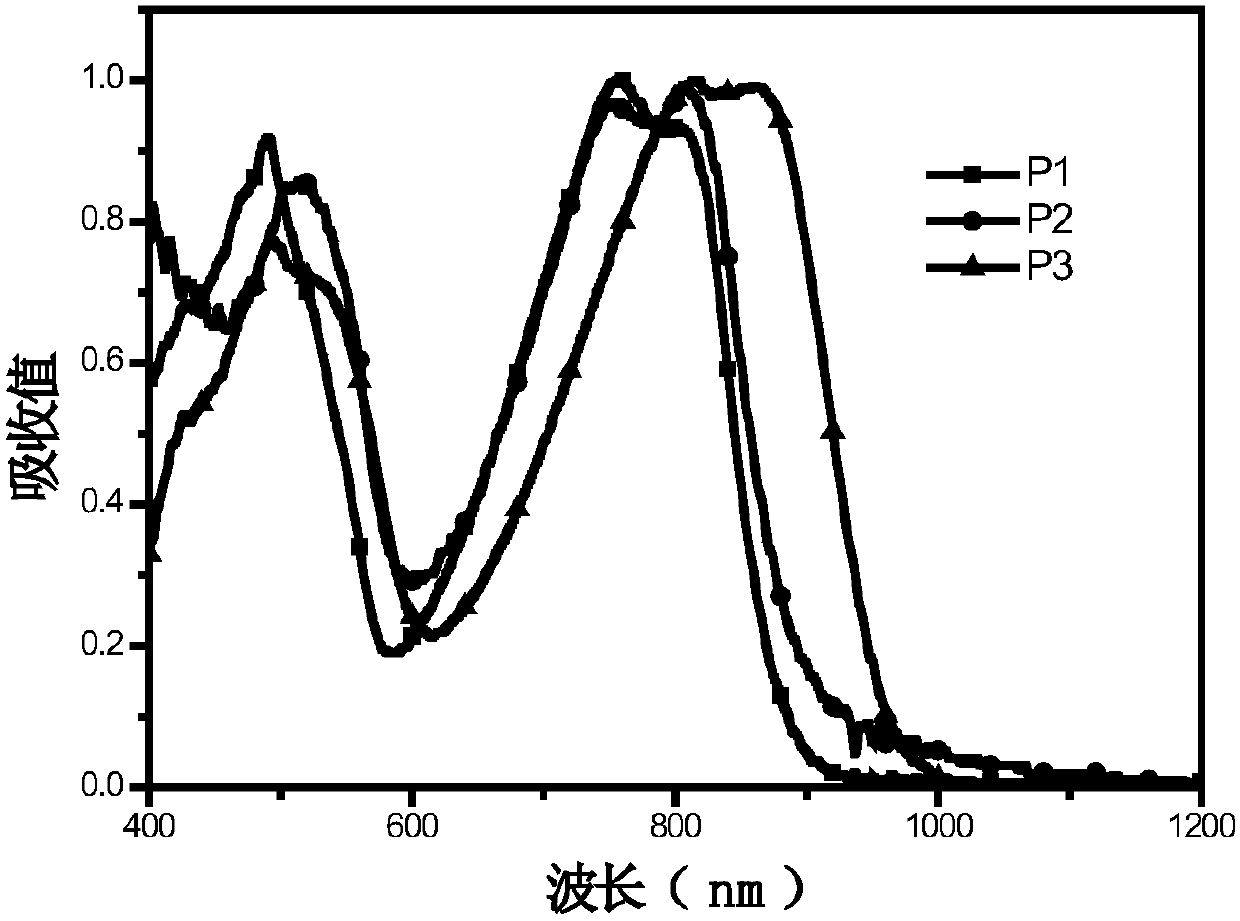

[0051] The conjugated polymers P1, P2, and P3 synthesized in Example 1 are used as active layers in organic photovoltaic devices (ITO anode / anode interface layer / active layer / cathode interface layer / cathode)

[0052] Pre-cut the ITO conductive glass with a square resistance of 20 ohms / cm2 into 15mm×15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to clean ultrasonically in sequence, blow nitrogen whistle, and place in a constant temperature oven for later use. A layer of 20nm thick PEDOT:PSS was spin-coated on the ITO, and then the active layer materials P1, P2, and P3 were spin-coated respectively, with a thickness of 100nm. Then spin-coat a layer of PFN-Br with a thickness of 5nm, and finally evaporate Al electrodes. All preparations were carried out in a glove box under a nitrogen atmosphere. The current-voltage curves of the prepared positive battery devices are as follows: Figure 4 The relevant data a...

Embodiment 3

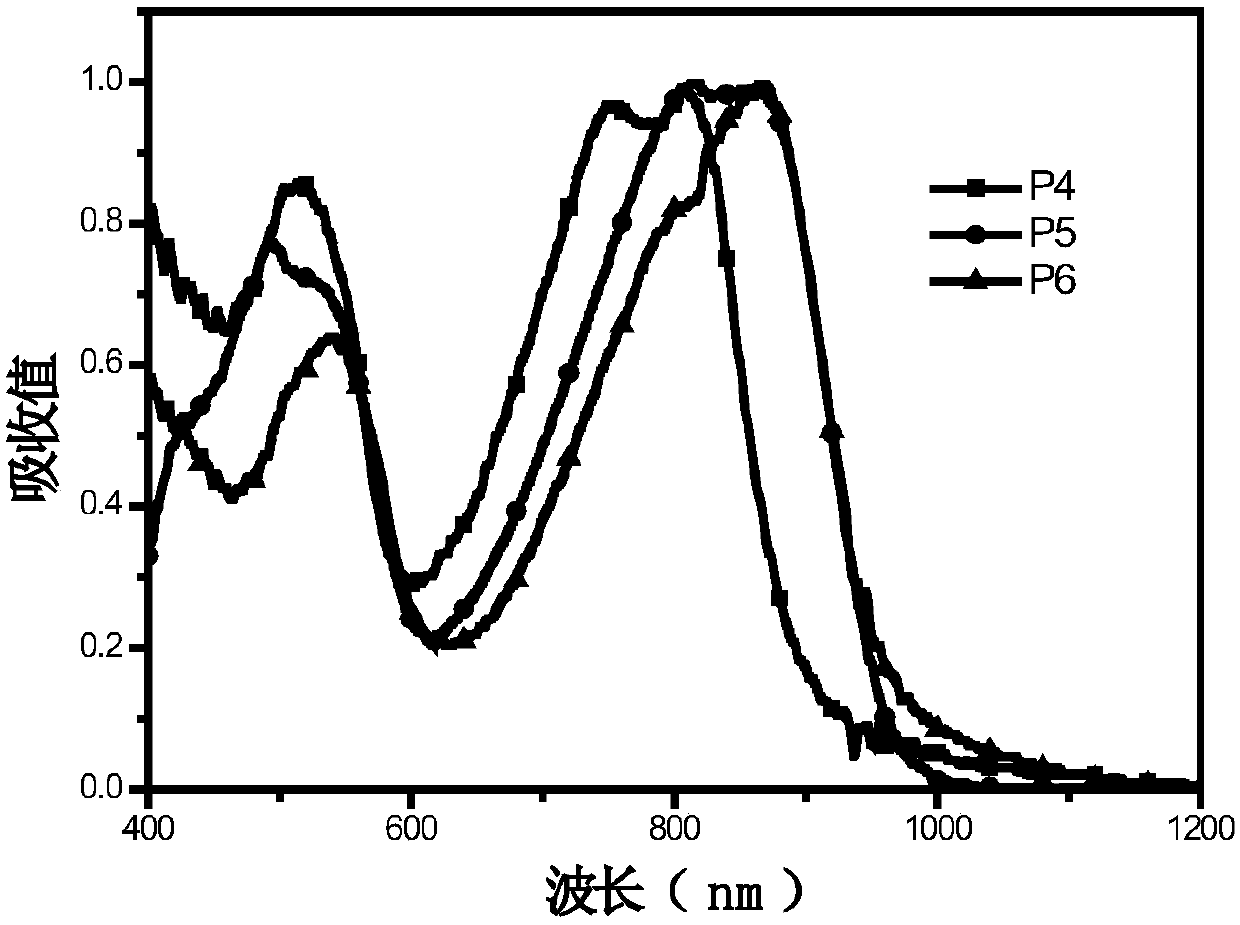

[0054] The conjugated polymers P4, P5, and P6 synthesized in Example 1 are used as active layers in organic photovoltaic devices (ITO anode / anode interface layer / active layer / cathode interface layer / cathode)

[0055] Pre-cut the ITO conductive glass with a square resistance of 20 ohms / cm2 into 15mm×15mm square pieces. Use acetone, special detergent for micron-sized semiconductors, deionized water, and isopropanol to clean ultrasonically in sequence, blow nitrogen whistle, and place in a constant temperature oven for later use. Spin-coat a layer of PEDOT:PSS with a thickness of 20 nm on the ITO, and then spin-coat the active layer materials P4, P5, and P6 respectively, each with a thickness of 100 nm. Then spin-coat a layer of PFN-Br with a thickness of 5nm, and finally evaporate Al electrodes. All preparations were carried out in a glove box under a nitrogen atmosphere. The current-voltage curves of the prepared positive battery devices are as follows: Figure 5 The relevan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com