Water-based organic silicon fluorine modified graphene oxide/epoxy resin coating and preparation method thereof

A technology of epoxy resin coating and silicon fluorine modification, which is applied in the field of coatings to achieve good anti-corrosion properties, improve hardness and promote dispersion.

- Summary

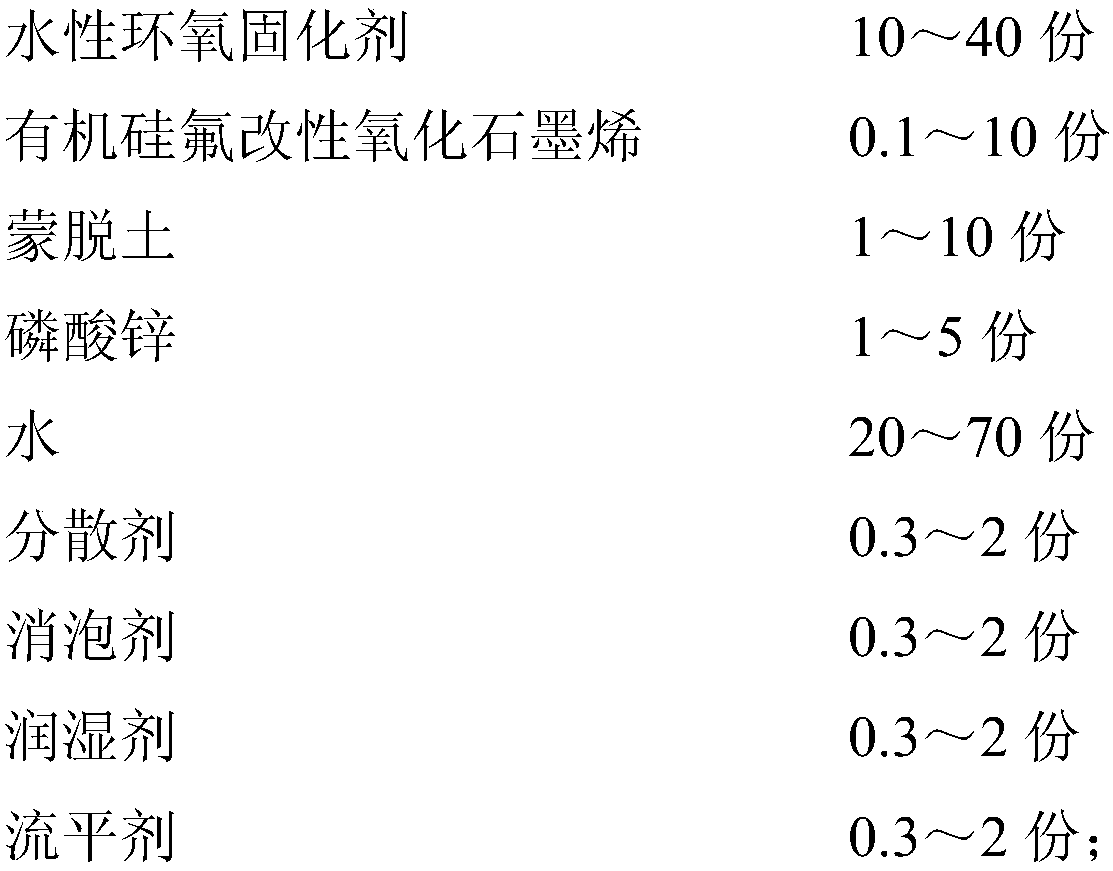

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

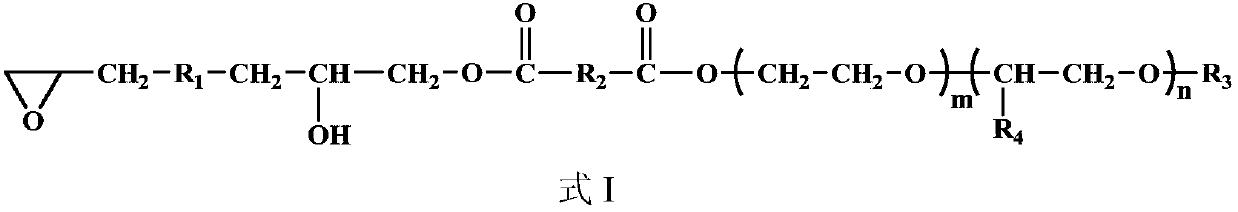

[0063] (1) Preparation of hydrophilic polyether modified epoxy resin:

[0064] Add 5 parts of maleic anhydride, 54 parts of polyethylene glycol monomethyl ether ((CH 3 O(CH 2 CH 2 O) n H), relative molecular weight 5000) and 60 parts of toluene, heated up to 80°C, added 1 part of p-toluenesulfonic acid, stirred for 7 hours, then added 25 parts of F-44 novolac epoxy resin and 2 parts of benzyl triethyl ammonium chloride, heated to 100°C, stirred and reacted for 12 hours, and the solvent was distilled off under reduced pressure to obtain a hydrophilic polyether-modified epoxy resin; the parts are parts by mass;

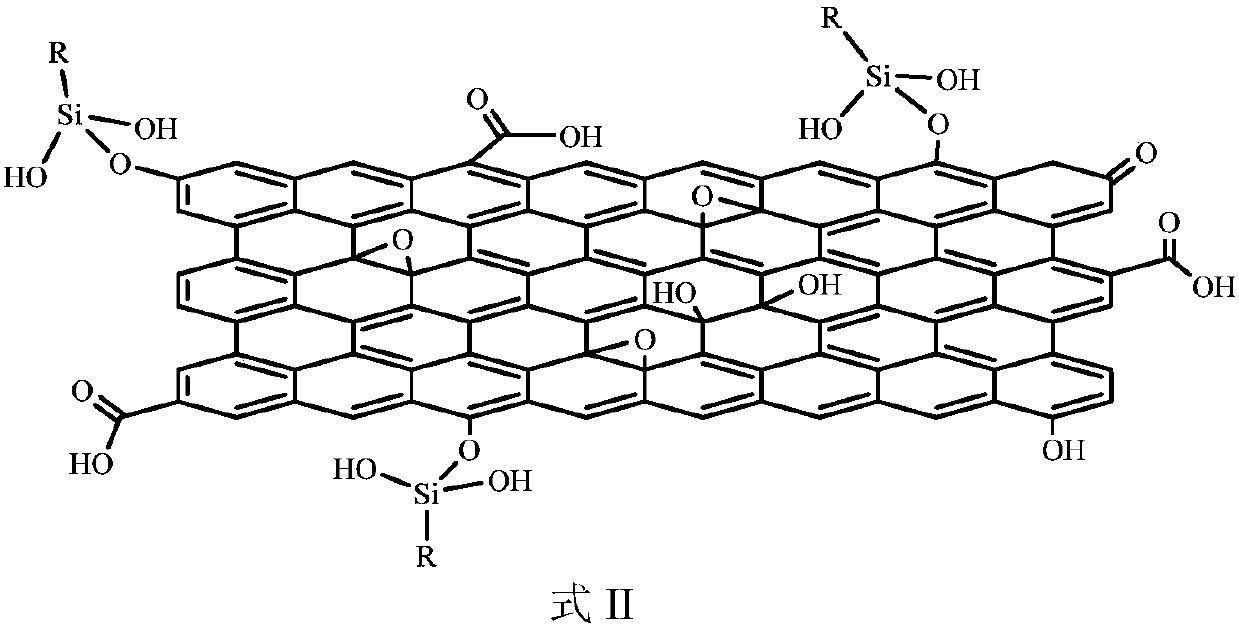

[0065] (2) Preparation of organosilicon-fluorine modified graphene oxide:

[0066] Add 70 parts of ethanol, 15 parts of deionized water, 2 parts of γ-aminopropyltriethoxysilane, 3 parts of ethyl orthosilicate, 5 parts of trifluoropropyltrimethoxysilane into the container, and heat up to 50°C , add 5 parts of ammonia water, stir and react for 2 hours, then add 5 par...

Embodiment 2

[0072] (1) Preparation of hydrophilic polyether modified epoxy resin:

[0073] Add 10 parts of succinic anhydride, 30 parts of polyethylene glycol butyl ether (relative molecular mass 600) and 40 parts of toluene into the container, heat up to 80°C, add 1 part of triethylamine, stir for 7 hours, and then add 25 parts of E -51 type epoxy resin and 2 parts of triphenylphosphine, heat up to 100°C, stir and react for 12 hours, and distill off the solvent under reduced pressure to obtain a hydrophilic polyether-modified epoxy resin; the parts are parts by mass;

[0074] (2) Preparation of organosilicon-fluorine modified graphene oxide:

[0075] Add 70 parts of ethanol, 15 parts of deionized water, 2 parts of γ-aminopropyltriethoxysilane, 3 parts of ethyl orthosilicate, 5 parts of hexafluorobutylpropyltrimethoxysilane in the container, and heat up to 50°C, add 5 parts of ammonia water, stir and react for 2 hours, then add 5 parts of graphene oxide, continue to react for 1 hour, coo...

Embodiment 3

[0081] (1) Preparation of hydrophilic polyether modified epoxy resin:

[0082] Add 10 parts of phthalic anhydride, 40 parts of polyethylene glycol monomethyl ether (molecular mass: 2000) and 50 parts of toluene into the container, raise the temperature to 80°C, add 1 part of dibutyltin dilaurate, and stir for 7 Hours, then add 25 parts of F-51 type novolac epoxy resin and 2 parts of triethylamine, heat up to 100 ° C and stir for 12 hours, and distill off the solvent under reduced pressure to obtain a hydrophilic polyether-modified epoxy resin; parts by mass;

[0083] (2) Preparation of organosilicon-fluorine modified graphene oxide:

[0084] Add 70 parts of ethanol, 15 parts of deionized water, 2 parts of γ-aminopropyltriethoxysilane, 3 parts of ethyl orthosilicate, 5 parts of hexafluorobutylpropyltrimethoxysilane in the container, and heat up to 60°C, add 5 parts of acetic acid, stir and react for 2 hours, then add 5 parts of graphene oxide, continue to react for 1 hour, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com