Composite scale-inhibiting corrosion-inhibiting bactericide and preparation method thereof

A scale and corrosion inhibition, fungicide technology, applied in the direction of fungicides, botanical equipment and methods, biocides, etc., can solve problems such as scaling, increased corrosion tendency, deterioration of circulating water quality, and growth of bacteria and algae, etc., to achieve Reduce the frequency of dosing, the performance of the medicine is excellent, and the effect of avoiding the growth of bacteria and algae

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

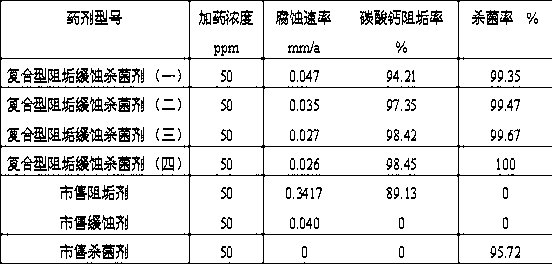

Examples

Embodiment 1

[0031] In terms of parts by weight, the composite antiscaling and corrosion inhibiting bactericide is prepared from the following raw materials in parts by weight, 20 parts of ethanol, 30 parts of dodecyl dimethyl benzyl ammonium chloride, 10 parts of hydroperoxide, 2- 7 parts of hydroxyphosphinoacetic acid, 8 parts of polyaspartic acid, 5 parts of sodium pentachlorophenate, 20 parts of soft water.

[0032] step 1:

[0033] Check whether the reaction kettle is clean, close all valves, pump 20 parts of soft water, and start stirring.

[0034] Step 2:

[0035] Add 20 parts of ethanol in the reactor.

[0036] Step 3:

[0037] Add 30 parts of dodecyl dimethyl benzyl ammonium chloride, 10 parts of hydrogen peroxide, 7 parts of 2-hydroxyphosphinoacetic acid, 8 parts of polyaspartic acid, 5 parts of sodium pentachlorophenate to the reactor in turn. Each time a product is added, stir for 10 minutes respectively. After adding the raw materials, stir for 30 minutes to obtain the fi...

Embodiment 2

[0040] Example 2: In terms of parts by weight, the composite anti-scaling and corrosion-inhibiting fungicide is prepared from the following raw materials in parts by weight: 20 parts of methanol, 30 parts of tetradecyldimethylbenzyl ammonium chloride, and 10 parts of hydrogen peroxide , 7 parts of 2-hydroxyphosphinoacetic acid, 8 parts of polyaspartic acid, 7 parts of dichlorophen, 18 parts of soft water.

[0041] step 1:

[0042] Check whether the reaction kettle is clean, close all valves, pump 18 parts of soft water, and start stirring.

[0043] Step 2:

[0044] Add 20 parts of methanol into the reactor.

[0045] Step 3:

[0046] Add 30 parts of tetradecyl dimethyl benzyl ammonium chloride, 10 parts of hydrogen peroxide, 7 parts of 2-hydroxyphosphinoacetic acid, 8 parts of polyaspartic acid, and 7 parts of sodium dichlorophenate to the reactor in turn. Each time a product is added, stir for 10 minutes respectively. After adding the raw materials, stir for 30 minutes to...

Embodiment 3

[0050] In terms of parts by weight, the composite antiscaling and corrosion inhibiting bactericide is prepared from the following raw materials in parts by weight, 20 parts of methanol, 30 parts of dodecyl dimethyl benzyl ammonium chloride, 10 parts of hydrogen peroxide, 2-hydroxy 7 parts of phosphinoacetic acid, 8 parts of polyaspartic acid, 7 parts of dichlorophen, 18 parts of soft water.

[0051] step 1:

[0052] Check whether the reaction kettle is clean, close all valves, pump 18 parts of soft water, and start stirring.

[0053] Step 2:

[0054] Add 20 parts of methanol into the reactor.

[0055] Step 3:

[0056] Add 30 parts of dodecyl dimethyl benzyl ammonium chloride, 10 parts of hydrogen peroxide, 7 parts of 2-hydroxyphosphinoacetic acid, 8 parts of polyaspartic acid, 7 parts of sodium dichlorophenate to the reactor in turn. Each time a product is added, stir for 10 minutes respectively. After adding the raw materials, stir for 30 minutes to obtain the finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com