Functional organic nutrient solution for plants and preparation method of functional organic nutrient solution

A technology of organic nutrition and nutrient solution, which is applied in the field of modern agriculture, can solve the problems of high price, unstable effect, single nutrient composition, etc., and achieve the effect of optimized treatment, comprehensive nutrient composition and comprehensive nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

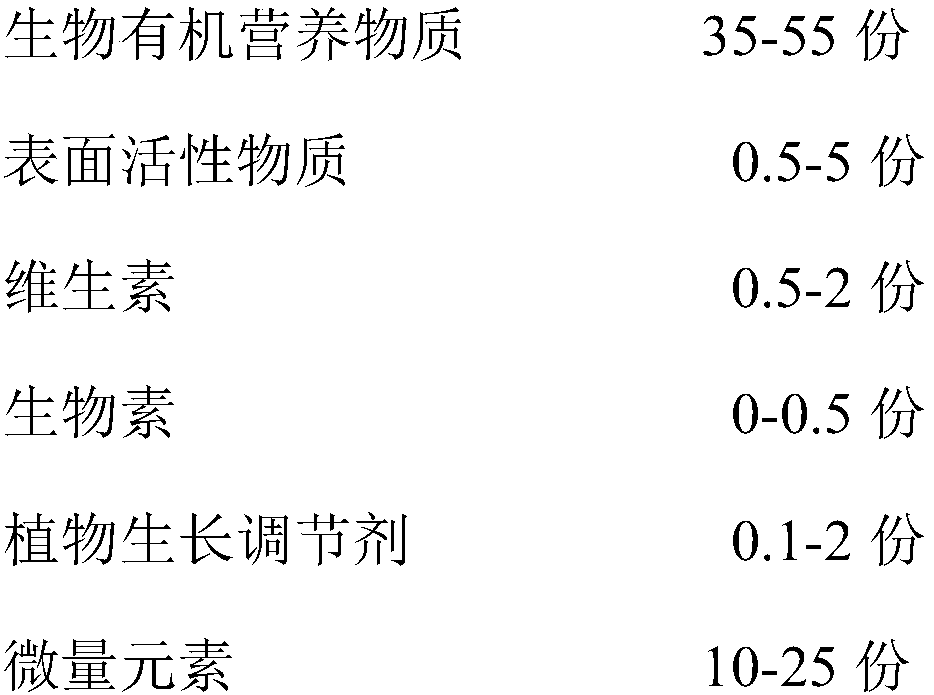

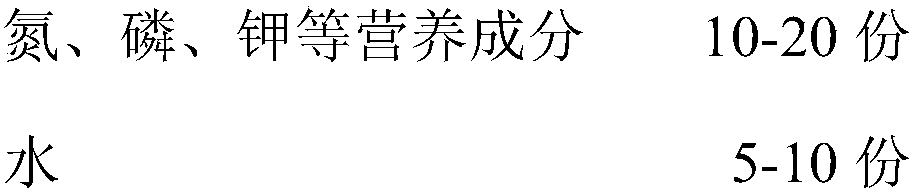

Method used

Image

Examples

preparation example Construction

[0045] A method for preparing functional plant organic nutrient solution comprises three steps of primary fermentation, secondary fermentation and mixing of multi-nutrient components. The first fermentation is divided into two parts. One is to obtain biochemical fulvic acid by fermenting corn stalks at a temperature of 30-70°C for 5-7 days, so that agricultural waste can be recycled and reduce its impact on the environment due to improper treatment. The impact of hazards; the second is obtained from the hydrolysis of inedible marine fish by a compound enzyme composed of alkaline protease and papain, at a temperature of 50-60 ° C and a time of 5-6 hours, to obtain compound amino acids. This type of nutrition contains C, N Nutrients needed by plants. In the utilization of crop straw and bagasse, the method of graded utilization is adopted, and the cellulose and hemicellulose are separated first, and the remaining lignin is fermented to obtain a fermented liquid rich in nutrients...

Embodiment 1

[0049] (1) Biochemical fulvic acid is obtained by fermenting corn stalks at a temperature of 30-70°C for 5-7 days;

[0050] (2) It is obtained by hydrolyzing inedible marine fish with a compound enzyme composed of alkaline protease, papain, etc., at a temperature of 50-60°C and a time of 5-6 hours to obtain compound amino acids;

[0051] (3) Mix the obtained biochemical fulvic acid, compound amino acid and molasses liquid in a weight ratio of 1:1:8, and then carry out secondary fermentation at 30-70°C for 3 days to obtain uniformly mixed bio-organic nutrients;

[0052] (4) At 30-50°C, add 10 parts (weight) of water and 15 parts (weight) of trace elements to 40 parts (weight) of biological organic nutrients, and add 15 parts (weight) of nutrients such as nitrogen, phosphorus, and potassium after dissolving completely. part (weight), after dissolving completely, add 0.5 part (weight) of surfactant Tween-80, 0.5 part (weight) of vitamin B2, 0.1 part (weight) of biotin, plant grow...

Embodiment 2

[0054] (1) Biochemical fulvic acid is obtained by fermenting corn stalks at a temperature of 30-70°C for 5-7 days;

[0055] (2) It is obtained by hydrolyzing inedible marine fish with a compound enzyme composed of alkaline protease, papain, etc., at a temperature of 50-60°C and a time of 5-6 hours to obtain compound amino acids;

[0056] (3) Mix the obtained biochemical fulvic acid, compound amino acid and molasses liquid in a weight ratio of 1:1:8, and then carry out secondary fermentation at 30-70°C for 3 days to obtain uniformly mixed bio-organic nutrients;

[0057] (4) At 30-50°C, add 5 parts (weight) of water and 12 parts (weight) of trace elements to 36 parts (weight) of bio-organic nutrients, and add 18 parts of nutrients such as nitrogen, phosphorus, and potassium after the dissolution is complete. part (weight), after dissolving completely, add 0.5 part (weight) of surface active substance Tween-80, 0.1 part (weight) of polyoxyethylene-containing organic silicon, 0.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com