Anti-radon and anti-formaldehyde coating

An anti-formaldehyde and paint technology, applied in the field of paint manufacturing, can solve the problems of anti-radon, anti-formaldehyde adhesion, poor fast curing performance, etc., and achieve the effect of shortening curing time, increasing adhesion and promoting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

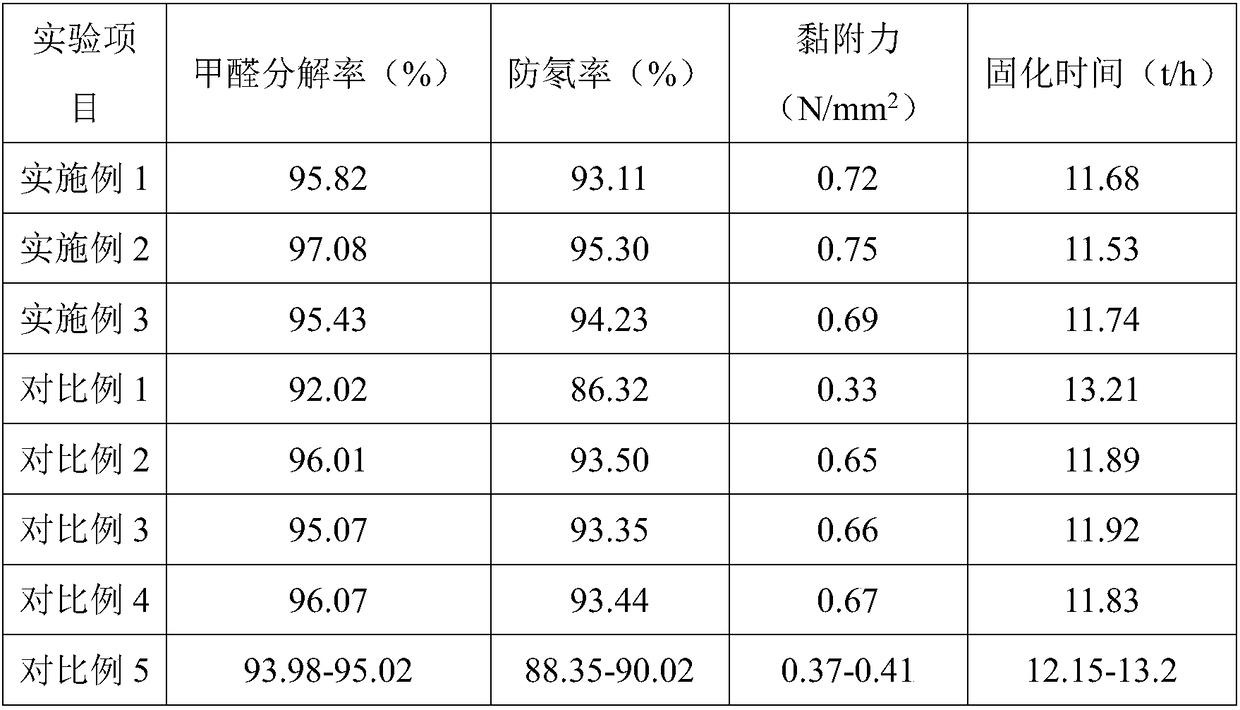

Examples

Embodiment 1

[0031]A kind of anti-radon, anti-formaldehyde coating, with weight part as unit, comprises following raw material: 21 parts of bisphenol A type epoxy resin, 33 parts of ethylene-vinyl acetate copolymer emulsion, 9 parts of nanometer glass hollow microspheres, nanometer dioxide 9 parts of silicon, 7 parts of wollastonite powder, 5 parts of kaolin, 26 parts of sodium carboxymethylcellulose, 3 parts of titanate coupling agent, 4 parts of barium oxide compound, 3 parts of ethoxylated alkylphenol ammonium sulfate , 3 parts of nano-silver particles, 17 parts of polyurethane resin, 11 parts of sodium lignosulfonate, 8 parts of malic acid, 2 parts of bamboo charcoal powder, 1 part of star anise oil, 1 part of propylene glycol butyl ether, 77 parts of water;

[0032] The production technology of described anti-radon, anti-formaldehyde coating comprises the following steps:

[0033] S1. Ingredients: ethylene-vinyl acetate copolymer emulsion, nano glass hollow microspheres, titanate coup...

Embodiment 2

[0037] A radon-proof and formaldehyde-resistant coating, which comprises the following raw materials in parts by weight: 24 parts of bisphenol A epoxy resin, 38 parts of ethylene-vinyl acetate copolymer emulsion, 13 parts of nano-glass hollow microspheres, nano-dioxide 11 parts of silicon, 9 parts of wollastonite powder, 6 parts of kaolin, 27 parts of sodium carboxymethylcellulose, 4 parts of titanate coupling agent, 6 parts of barium oxide compound, 5 parts of ethoxylated alkylphenol ammonium sulfate , 4 parts of nano-silver particles, 19 parts of polyurethane resin, 13 parts of sodium lignosulfonate, 10 parts of malic acid, 3 parts of bamboo charcoal powder, 2 parts of star anise, 2 parts of propylene glycol butyl ether, 89 parts of water;

[0038] The production technology of described anti-radon, anti-formaldehyde coating comprises the following steps:

[0039] S1. Ingredients: ethylene-vinyl acetate copolymer emulsion, nano glass hollow microspheres, titanate coupling age...

Embodiment 3

[0043] A radon-proof and formaldehyde-resistant coating, which comprises the following raw materials in parts by weight: 24 parts of bisphenol A epoxy resin, 39 parts of ethylene-vinyl acetate copolymer emulsion, 15 parts of nano-glass hollow microspheres, nano-dioxide 12 parts of silicon, 10 parts of wollastonite powder, 7 parts of kaolin, 28 parts of sodium carboxymethyl cellulose, 6 parts of titanate coupling agent, 7 parts of barium oxide compound, 6 parts of ethoxylated alkylphenol ammonium sulfate , 6 parts of nano-silver particles, 22 parts of polyurethane resin, 15 parts of sodium lignosulfonate, 12 parts of malic acid, 5 parts of bamboo charcoal powder, 3 parts of star anise oil, 3 parts of propylene glycol butyl ether, 94 parts of water;

[0044] The production technology of described anti-radon, anti-formaldehyde coating comprises the following steps:

[0045] S1. Ingredients: ethylene-vinyl acetate copolymer emulsion, nano glass hollow microspheres, titanate coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com