Catalyst for preparing acrylic acid and methyl acrylate

A methyl acrylate and catalyst technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, carboxylate preparations, etc., can solve the problems of unsatisfactory large-scale production, easy loss of active components, and complex influencing factors, so as to reduce production Maintenance costs, improved activity and stability, and simple industrial preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation of embodiment 1 catalyst

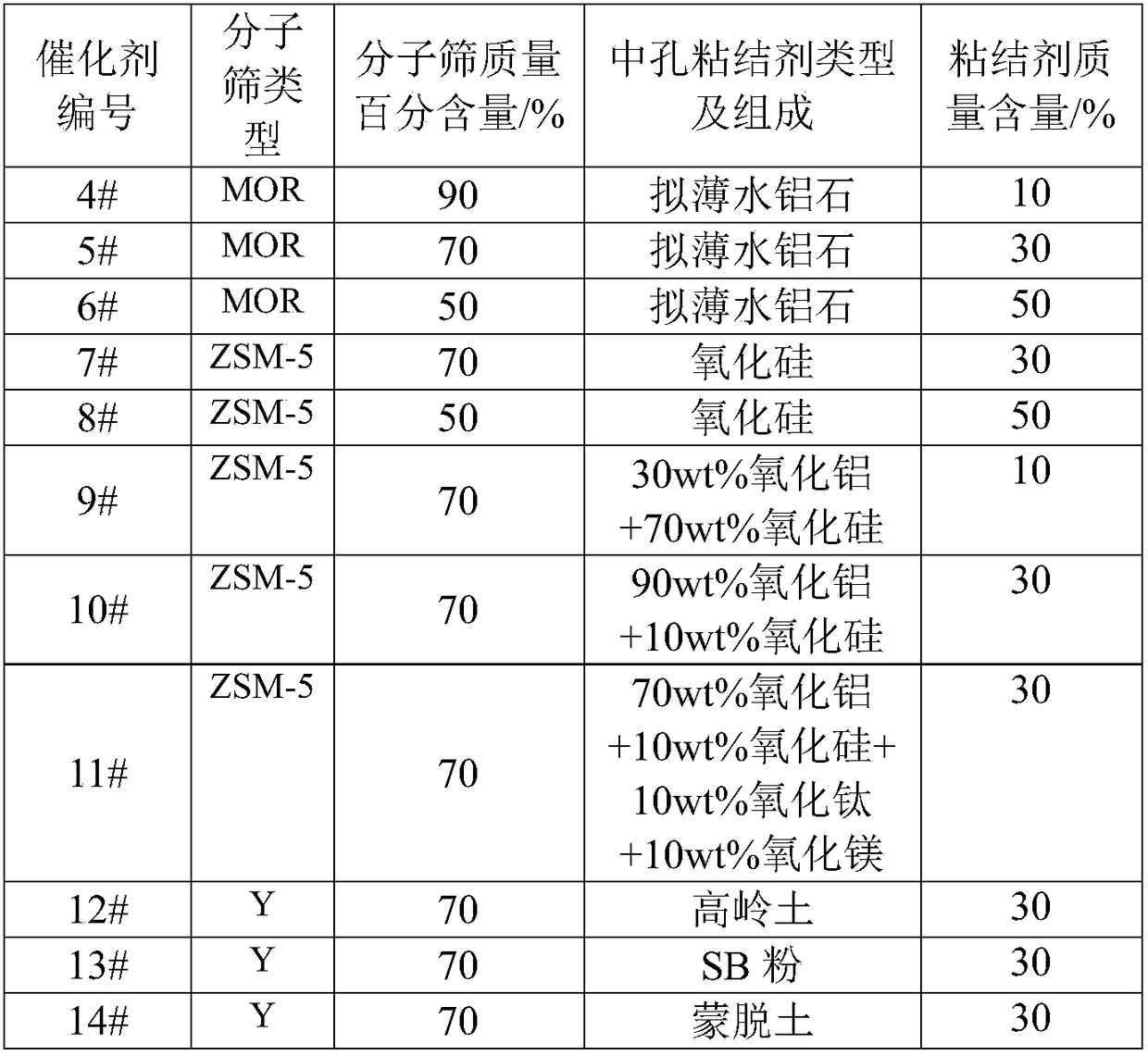

[0056] Pseudoboehmite (SB powder), silicon oxide, magnesium oxide, titanium oxide, kaolin and montmorillonite (purchased from Shanghai Zhuoyue Chemical Technology Co., Ltd.) were selected as binders. The specific indicators of the binder are shown in Table 1. With comparative example 1 to 3 identical ZSM-5, MOR, Y molecular sieve (concrete consumption sees table 2) and binding agent (concrete consumption sees table 2) and 10% dilute nitric acid are mixed and extruded and formed, after roasting, Exchanged with 0.5mol / L ammonium nitrate three times (2 hours / time), washed with deionized water, dried, and calcined at 550°C for 4 hours to obtain the catalyst, see Table 2.

[0057] Table 1 Binder specific indicators

[0058] Binder type

Mesopore specific surface area of the binder (m 2 / g)

Metal impurity content in binder (wt%)

250

0.1

SB powder

289

0.2

Silicon ox...

Embodiment 2

[0061] Embodiment 2: the reaction performance of catalyst

[0062] Granulate D1#~D3# and 4#~12# catalysts into 20-40 mesh. 0.4 g of the catalyst was filled into a fixed-bed reactor for pretreatment. Catalyst pretreatment conditions are: N 2 The flow rate is 30mL / min, starting from 25°C over 150min to 500°C, and maintaining at 500°C for 180min.

[0063] The reaction gas is composed of two channels, one of which is the raw material methylal, which is brought into the reactor by CO under the condition of a water bath temperature of 30°C; the other is pure CO. By adjusting the amount and ratio of the above two paths of gas, different carbon monoxide: formaldehyde ratios, total reaction pressure, reaction temperature, space velocity, catalyst conditions and reaction results are listed in Table 3. Among them, the raw materials of formaldehyde compounds with test numbers 11, 12, and 13 in Table 3 are: formaldehyde, paraformaldehyde, and a mixture of formaldehyde and methylal in a ...

Embodiment 3

[0068] Pseudoboehmite, silicon oxide, magnesium oxide, titanium oxide, kaolin and montmorillonite were selected as binders respectively. The specific composition of the binder is shown in Table 4. ZSM-5, ZSM-35 and EMT molecular sieves with different silicon-aluminum ratios (all purchased from Shanghai Zhuoyue Chemical Technology Co., Ltd.) and binders with different mass fractions were mixed evenly with 10% dilute nitric acid and extruded into strips. After roasting, Exchanged with 0.5 mol / L ammonium nitrate three times (2 hours / time), washed with deionized water, dried, and calcined at 550° C. for 4 hours to obtain the catalyst. 0.4 g of the catalyst was filled into a fixed-bed reactor for pretreatment. Catalyst pretreatment conditions are: N 2 The flow rate is 30mL / min, starting from 25°C over 150min to 500°C, and maintaining at 500°C for 180min. The reaction gas is composed of three channels, and the total flow rate is guaranteed to be 100mL / min. The raw material methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com