High-mobility co-doped tellurium zinc cadmium crystal used for nuclear radiation detection and preparation method of crystal

A high-mobility, co-doping technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., to improve carrier transport performance, electron mobility, and resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1: put the CZT raw material mixed with 100ppm In and 1000ppm Yb into a quartz ampoule and mix well.

[0038] The second step: vacuumize the quartz, the vacuum degree reaches 5×10 -5 Seal the tube at Pa, and then place the quartz ampoule in ACRT-B crystal growth equipment for growth.

[0039] Step 3: Take out the grown quartz ampoule, cut it with an external circular cutting machine, take out the crystal ingot, and cut the crystal ingot and wafer with a diamond wire cutting machine.

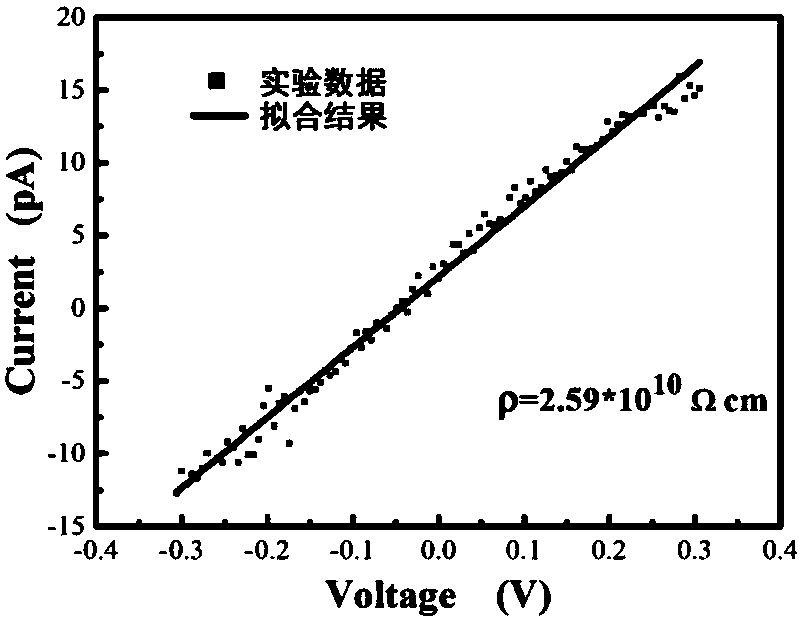

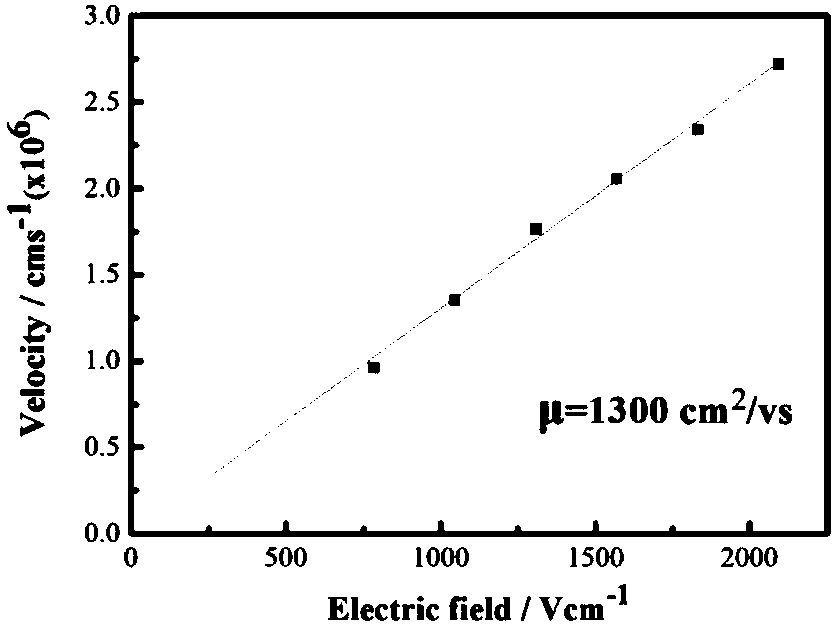

[0040] Step 4: Plate the cut 5*5mm wafer with electrodes, measure the resistivity, and use the laser-induced transient photocurrent test system to measure the electron mobility. The electron mobility is 1340cm 2 / Vs.

Embodiment 2

[0042] Step 1: put the CZT raw material mixed with 50ppm In and 800ppm Yb into a quartz ampoule and mix well.

[0043] The second step: vacuumize the quartz, the vacuum degree reaches 5×10 -5 Seal the tube at Pa, and then place the quartz ampoule in ACRT-B crystal growth equipment for growth.

[0044] The growth parameters are as follows: set the target temperature in the high temperature zone as 1200-1150°C, the low temperature zone as 1050-1000°C, and the heating time as 12 hours; after reaching the target temperature, overheat at 10-50°C above the melting point for 1-24 hours, Finally, the crucible is lowered at a rate of 1-2 mm per hour, and the supporting rod stops falling after 75 to 150 hours after starting to drop, and the temperature is cooled to room temperature.

[0045] Step 3: Take out the grown quartz ampoule, cut it with an external circular cutting machine, take out the crystal ingot, and cut the crystal ingot and wafer with a diamond wire cutting machine.

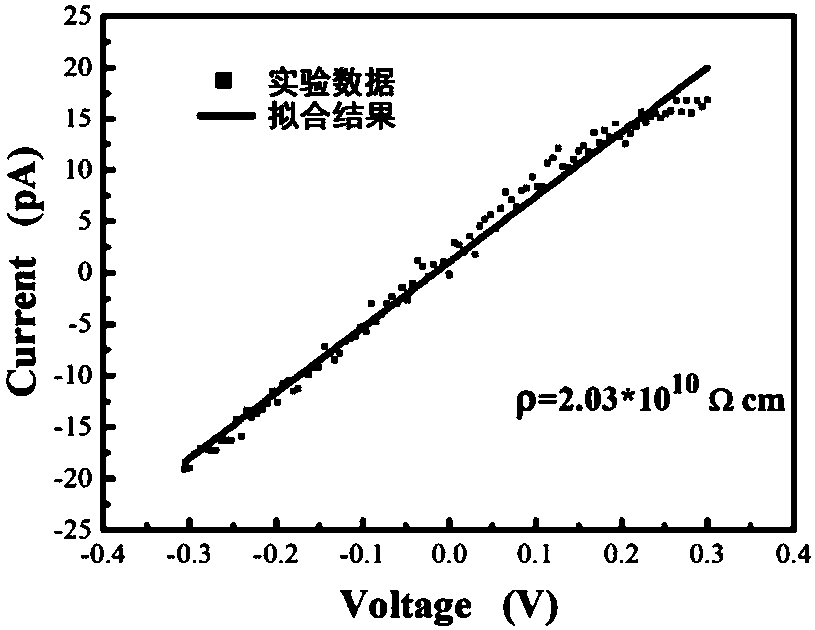

...

Embodiment 3

[0048] Step 1: put the CZT raw material mixed with 30ppm In and 500ppm Yb into a quartz ampoule and mix well.

[0049] The second step: vacuumize the quartz, the vacuum degree reaches 5×10 -5 Seal the tube at Pa, and then place the quartz ampoule in ACRT-B crystal growth equipment for growth.

[0050] The growth parameters are as follows: set the target temperature in the high temperature zone as 1200-1150°C, the low temperature zone as 1050-1000°C, and the heating time as 12 hours; after reaching the target temperature, overheat at 10-50°C above the melting point for 1-24 hours, Finally, the crucible is lowered at a rate of 1-2 mm per hour, and the supporting rod stops falling after 75 to 150 hours after starting to drop, and the temperature is cooled to room temperature.

[0051] Step 3: Take out the grown quartz ampoule, cut it with an external circular cutting machine, take out the crystal ingot, and cut the crystal ingot and wafer with a diamond wire cutting machine.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com