A flexible ablation resistance film and its preparation method

A resistance thin film, flexible technology, applied in the field of flexible ablation resistance thin film and its preparation, can solve the problems that affect the reliability of flexible thin film, large interface thermal stress, difficult to meet engineering applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

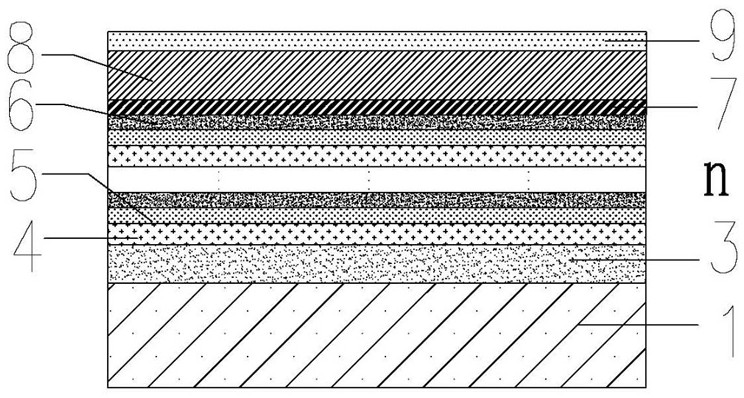

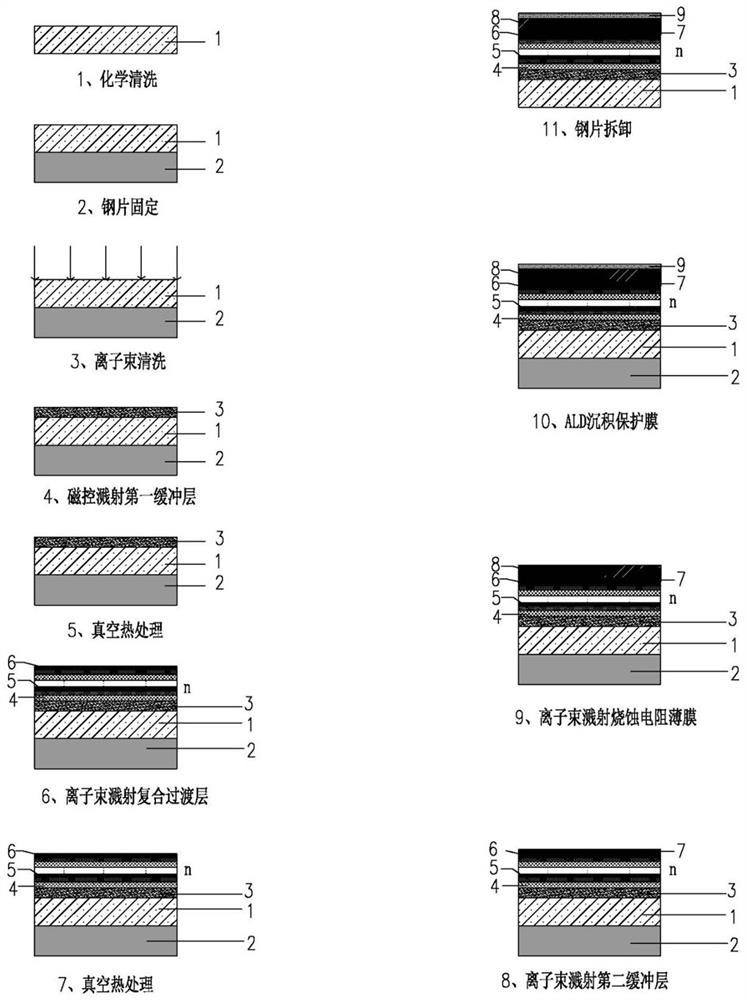

[0046] A flexible ablation resistive film, such as figure 1 , including a flexible substrate 1 and an ablation resistance film 8, a composite transition layer is provided between the flexible substrate 1 and the ablation resistance film 8, wherein the composite transition layer includes a sequentially deposited Si 3 N 4 Layer 4, AlN layer 5 to Al 2 o 3 Layer 6 periodic composite film.

[0047] In this embodiment, the periodic composite thin film is based on the flexible substrate 1 and presents "Si 3 N 4 Layer 4, AlN layer 5 to Al 2 o 3 Periodic change trend of layer 6". Specifically: take the flexible substrate 1 as the base surface to deposit Si in sequence 3 N 4 Layer 4, AlN layer 5, Al 2 o 3 Layer 6 forms Si 3 N 4 / AlN / Al 2 o 3 Composite thin films, periodically prepared Si 3 N 4 / AlN / Al 2 o 3 Composite thin film, obtain periodical composite thin film, namely composite transition layer.

[0048] In this embodiment, the period number of the periodic compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com