A kind of potassium zirconium carbide co-doped tungsten alloy and preparation method thereof

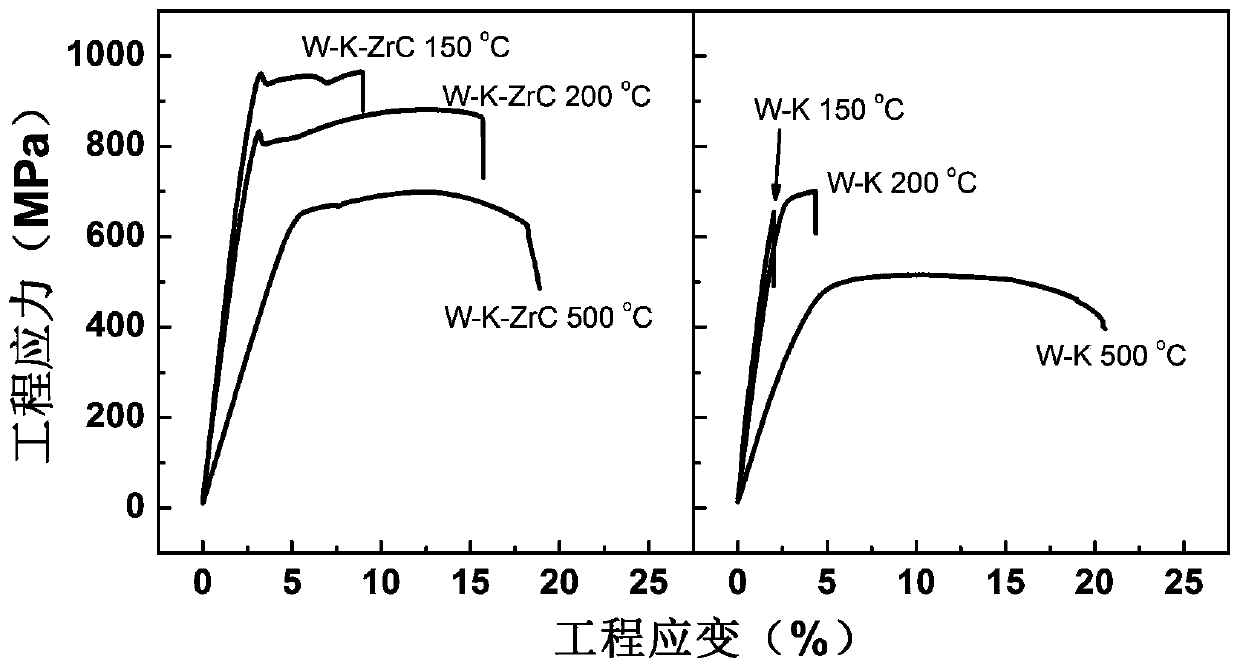

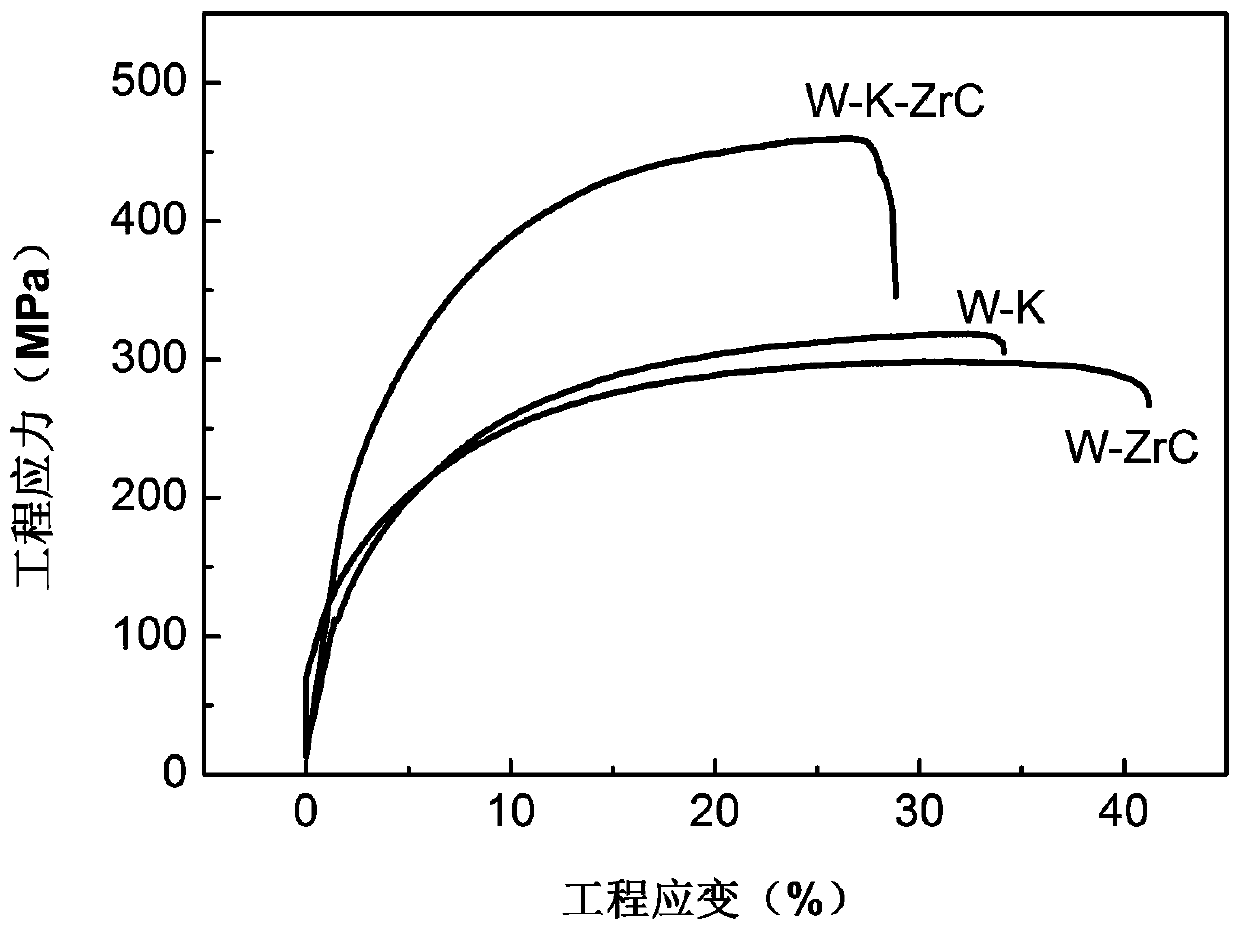

A zirconium carbide and co-doping technology, applied in the field of plasma wall materials, can solve the problems of poor plasma etching resistance of potassium-doped tungsten, low strength and toughness of bulk products, and achieve improved plasma etching resistance. corrosion resistance, excellent strength and high temperature stability, and the effect of improving low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific steps for the preparation of potassium zirconium carbide co-doped tungsten alloy are as follows:

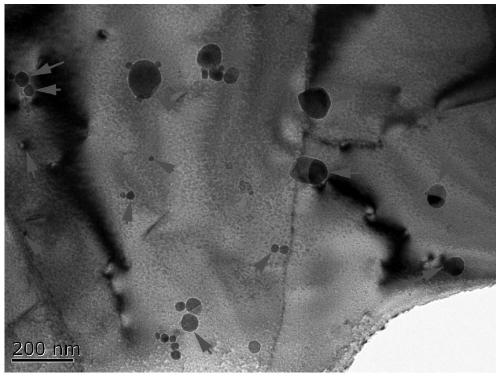

[0039] Step 1: Put potassium-doped tungsten powder and ZrC powder in the ratio of 99.5% by weight: 0.5% by ball milling in an argon atmosphere and mix them evenly to obtain a mixed powder, wherein K and Al in the potassium-doped tungsten powder , Si weight percentages are 0.011%, 0.004%, 0.022%, O content is 0.25%, the average particle size of potassium-doped tungsten powder is about 3.3 microns, and the average particle size of ZrC powder is 50nm.

[0040] Step 2: First put the mixture in the mold sleeve, press it into a green body with a cold isostatic press at a pressure of 200MPa, then place the green body in a dry flowing hydrogen atmosphere and sinter at 2000°C for 4 hours to obtain a relatively dense Alloy bulk forming.

[0041] Step 3: Hot rolling the sintered alloy block at 1000-1700°C for multiple passes, the deformation of each pass is 10-15%, and ...

Embodiment 2

[0049] The concrete steps of preparation are:

[0050] Step 1: According to the ratio of 98.5% by weight: 1.5%, ball mill and mix the doped tungsten powder and ZrC powder evenly in an argon atmosphere, wherein the doped tungsten powder contains K: 0.006%, Al: 0.01% , Si: 0.035%, O is less than or equal to 0.2% doped tungsten powder as the raw material, the particle size of the doped tungsten powder is 5.0μm, the particle size of the ZrC powder is about 100nm, and the V-type powder is used in an argon atmosphere. Blend with a mixer to obtain a homogeneous mixture.

[0051] Step 2: first put the mixture into a steel mold, and press it into a green body with a cold press at 300MPa, then place the green body in a hydrogen atmosphere or vacuum, and sinter it at 2300°C.

[0052] Step 2 can also adopt the direct thermocompression molding process, as follows:

[0053] The mixture is placed in a hydrogen atmosphere or a vacuum atmosphere, and is hot isostatically pressed and sintered...

Embodiment 3

[0058] The concrete steps of preparation are:

[0059] Step 1: According to the ratio of 99.8% by weight: 0.2%, the doped tungsten powder and ZrC powder are uniformly mixed with a mixer in an argon atmosphere to obtain a mixture, wherein the doped tungsten powder contains K : 0.02%, Al: 0.005%, Si: 0.025%, O less than or equal to 0.3%, the particle size of the doped tungsten powder is 1 μm, and the average particle size of the ZrC powder is 50 nm.

[0060] Step 2: First press the mixture under a pressure of 400MPa to form a green body, then place the green body in a flowing dry hydrogen atmosphere, and sinter at 2200°C for 5 hours to obtain a fairly dense alloy block.

[0061] Step 3: Rotate the sintered alloy block at 1100-1600°C, the initial forging temperature is 1500-1600°C, the terminal temperature is 1100-1300°C, the deformation amount per pass is about 10%, and the deformation amount is about 60 %, obtain dense tungsten alloy bulk.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com