Tantalum-based catalyst and applications of tantalum-based catalyst in 1,5-pentanediol preparation reaction through catalytic conversion of tetrahydrofurfuryl alcohol

A catalyst, pentanediol technology, used in molecular sieve catalysts, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as poor catalyst stability and vanadium loss, and achieve stable properties, The effect of facilitating recovery and regeneration and reducing the cost of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

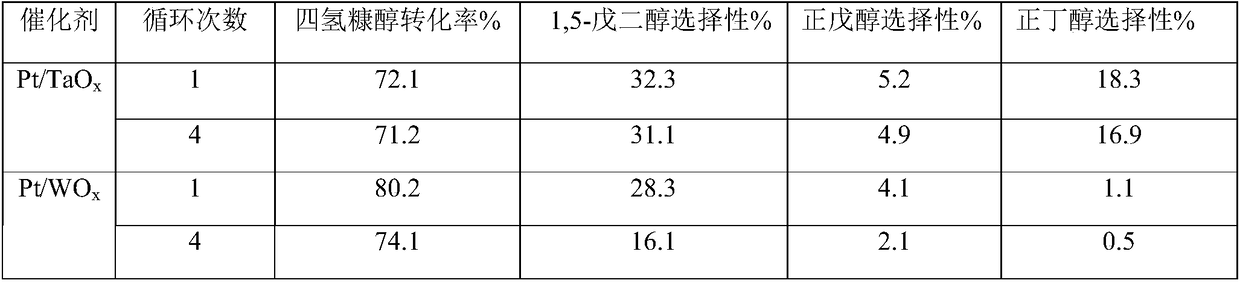

Examples

Embodiment 1

[0023] Alcohothermal Synthesis of TaO x Carrier: 3g of tantalum chloride was added to 100mL of ethanol, magnetically stirred at room temperature for 20min, and then transferred to a polytetrafluoroethylene-lined hydrothermal kettle at 160°C for alcohol thermal synthesis. Then vacuum-dried at 50°C for 6 hours to obtain TaO x (3x -t (t is alcohol thermal synthesis time).

[0024] In the same way, tungsten chloride can be replaced by tantalum chloride to obtain tungsten oxide WO x carrier.

Embodiment 2

[0026] Synthesis of Ta by soft template method 2 o 5 Carrier: Dissolve P-123 in propanol to form a solution with a mass fraction of 10%, add a certain amount of tantalum chloride to the solution, and stir vigorously for 30 minutes. Then add a small amount of deionized water (accounting for 1-15 wt% of the solvent) and stir for several minutes to further promote the alcoholysis. The sol was aged in air at 40°C for 5 days. The gel was calcined in the air at 300-450°C for 3 hours, and the obtained mesoporous tantalum supports synthesized by the hydrothermal method were respectively denoted as Ta 2 o 5 -T (T is the firing temperature).

Embodiment 3

[0028] Synthesis of tantalum oxide-supported noble metal catalyst: impregnate a certain amount of chloroplatinic acid solution on the tantalum oxide carrier synthesized by the above-mentioned alcohol thermal method, then dry at 120°C for 12h, roast at 400°C for 2h, and reduce in hydrogen at 300°C for 2h. That is to get 4wt%Pt / TaO x (3<x≤5, the same below) catalyst.

[0029] Other conditions remain the same, only the added salts containing active components are changed, and palladium chloride, chloroiridic acid, rhodium chloride, etc. are loaded on the tantalum oxide carrier respectively, and catalysts with different active components can be obtained. Pd / TaO x , Ir / TaO x , Rh / TaO x (Metal loadings are all 4 wt%).

[0030] In the same way, using commercial tantalum oxide as a carrier, 4wt% Pt / Ta 2 o 5 catalyst.

[0031] In the same way, the tungsten oxide WO prepared by the previous alcoholysis method x As a carrier, 4wt% Pt / WO can be produced x catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com