CoNiP/SiO2 catalyst and preparation method and application of CoNiP/SiO2 catalyst

A catalyst and catalytic hydrogenation technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and preparation of liquid hydrocarbon mixtures. It can solve problems such as corrosion reactors, catalyst coking, and catalyst deactivation, and achieve high content, High conversion rate and high dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Cobalt Nickel Hydroxide / SiO 2 preparation of

[0042] Add cobalt acetate and nickel acetate (the molar ratio of cobalt to nickel is 3:1) into water to dissolve completely, stir with a magnetic stirrer at 600r / min for 20min, add SiO 2 , magnetic stirrer 600r / min rotating speed stirs 20min, drips sodium hydroxide solution 100ml afterwards, the consumption of sodium hydroxide is three times of the molar weight sum of cobalt ion and nickel ion, magnetic stirrer 600r / min rotating speed stirs 25min, Co-precipitated cobalt-nickel hydroxide / SiO 2 of. Cobalt Nickel Hydroxide / SiO 2 Wash with water 3 to 4 times to make the filtrate neutral, wash with ethanol three times, and dry in an oven at 35°C for 8 hours to obtain cobalt-nickel hydroxide / SiO 2 solid.

[0043] 2) CoNiP / SiO 2 preparation of

[0044] The obtained cobalt nickel hydroxide / SiO 2 The solid is calcined in a nitrogen atmosphere in a tube furnace together with sodium hypophosphite. The mass of sodium hypopho...

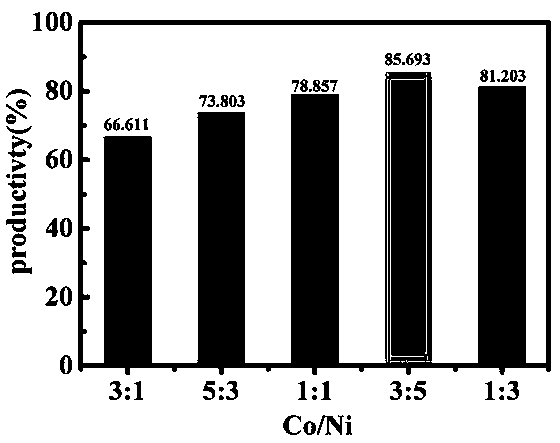

Embodiment 2~7

[0047] The molar ratio of cobalt to nickel in CoNiP and the loading amount of CoNiP are changed (see Table 1). The preparation methods and other parameters of Examples 2-7 are the same as those of Example 1.

[0048] Table 1

[0049]

Embodiment 8

[0051] The difference of this example is that in the preparation of CoNiP / SiO 2 In the process of calcining cobalt-nickel hydroxide / SiO 2 The conditions for the solid are as follows: the heating rate of the calcination is 5° C. per minute, the temperature is raised to 320° C., and the calcination is performed for 1 hour. Other parameters are the same as in Example 1.

[0052] characterize

[0053] The catalysts prepared in the above examples were characterized by the following means.

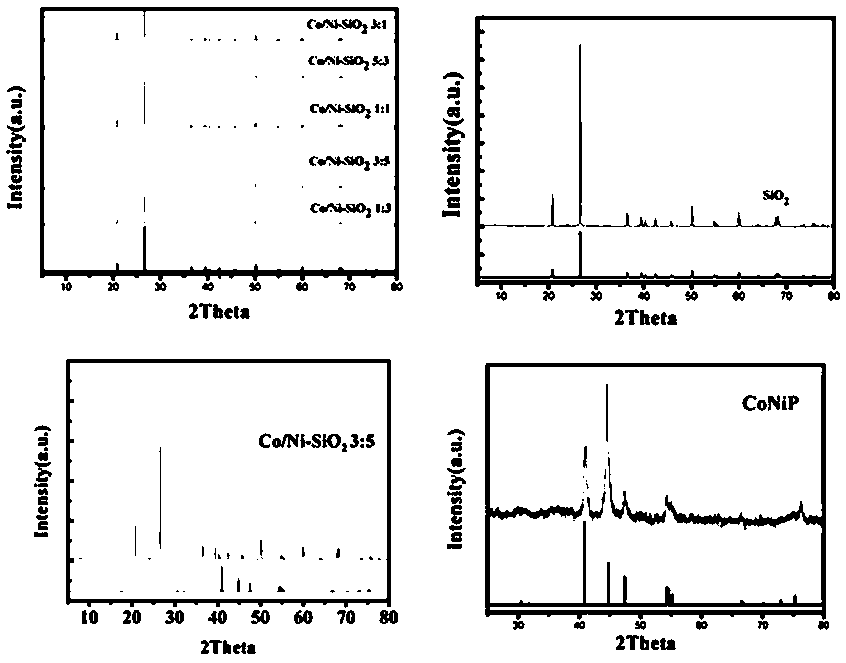

[0054] 1) HRTEM high resolution electron microscope, such as figure 1 shown. 2) Specific surface area and pore size distribution: use N 2 Adsorption and desorption methods, such as figure 2 shown. 3) X-ray photoelectron spectroscopy (XPS), such as image 3 shown.

[0055] From figure 1 It can be seen from the figure that when the molar ratio of cobalt to nickel in CoNiP is 3:5, the active ingredient CoNiP is evenly distributed without agglomeration and evenly dispersed. And the CoNiP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com