A method for photocatalytic removal of formaldehyde by zinc/antimony two-component supported nano-silicon carbide material

A nano-silicon carbide, two-component technology, applied in physical/chemical process catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of low specific surface area of materials, low photoelectric conversion efficiency, cumbersome preparation process, etc. Enhanced sensitivity, shortened degradation time, and strong adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of aminated nano silicon carbide particles:

[0038] 1) Put 10.0g of nano-silicon carbide particles (model DK-SiC-001, without any pretreatment) into 100ml of toluene solution, then add 0.3g of vinyl tris(β-methoxyethoxy)silane in nitrogen Reflux reaction under atmosphere for 2-5h;

[0039] 2) Cool down to room temperature, filter, wash with 30ml of acetone, and dry under reduced pressure at 60°C to obtain silanized surface-modified nano-silicon carbide particles;

[0040] 3) Place all the silanized surface-modified nano-silicon carbide particles obtained in step 2) in a mixed solution of 10ml of concentrated nitric acid and concentrated sulfuric acid (concentrated nitric acid and concentrated sulfuric acid are equal in weight) and immerse in ultrasonic for 24 hours, then filter and wash with water until the filtrate becomes After neutralization, dry under reduced pressure at 60°C to obtain nitrated nano-silicon carbide;

[0041] 4) Put nitrated nano-silic...

Embodiment 2

[0043] The preparation of zinc / antimony two-component supported nano-silicon carbide material with high specific surface area comprises the following steps:

[0044] 1) Put zinc sulfate heptahydrate (2.88g, 10mmol) and potassium antimony tartrate trihydrate into the aqueous solution, then add hexadecyltrimethylammonium bromide and stir for 10-30min to obtain the first mixed solution (by molar ratio Calculation, the molar ratio of zinc sulfate heptahydrate: potassium antimony tartrate trihydrate: cetyltrimethylammonium bromide is 3:1:0.4);

[0045] 2) Add aminated nano-silicon carbide particles (SiC-N) to the first mixed solution, raise the temperature to 60-80°C, stir and disperse evenly, then slowly add potassium hydroxide aqueous solution dropwise, adjust the pH to 10-11, and precipitate solid particles to deposit on The surface of the nano-silicon carbide particles and the inside of the pore diameter, and then heat-preserved and stirred for 24 hours to obtain a black mixtur...

Embodiment 3

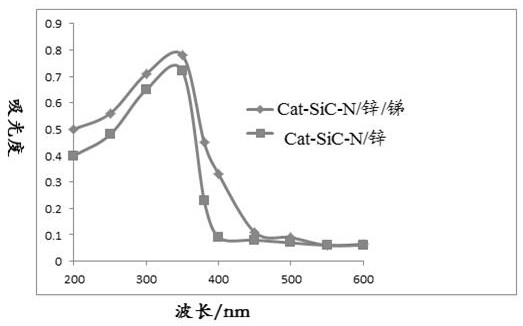

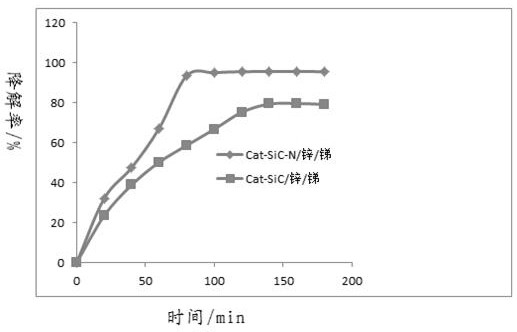

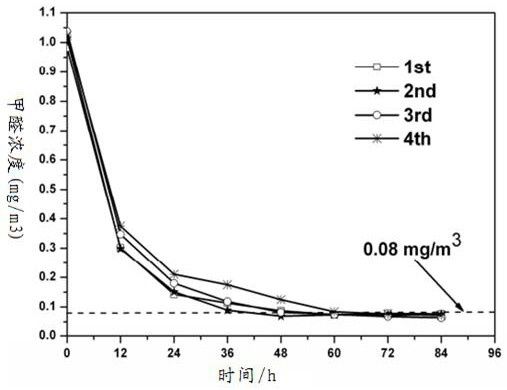

[0057] Formaldehyde wastewater degradation test: Dilute commercially available 37.0-40.0wt% formaldehyde aqueous solution with water to prepare formaldehyde aqueous solutions with different concentrations (10000mg / L, 600mg / L, 20mg / L), and use 600mg / L formaldehyde to test catalyst performance:

[0058] 1) Prepare 1L aqueous solution containing 600mg / L formaldehyde, adjust the pH to 9-10 with sodium hydroxide, then add nano-silicon carbide particles (DK-SiC-001), aminated nano-silicon carbide particles (SiC-N), Non-aminated modified zinc-antimony double hybrid nano-silicon carbide material (Cat-SiC / zinc / antimony), zinc hybrid nano-silicon carbide material (Cat-SiC-N / zinc) or nano-carbonization of zinc-antimony double hybrid Each 1g of silicon material (Cat-SiC-N / zinc / antimony) was stirred evenly to obtain the formaldehyde wastewater solution to be treated;

[0059] 2) Raise the temperature of the formaldehyde wastewater solution to be treated to 45°C, place it under a 30W ultrav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com