Method for improving crystallization performance and thermal performance of PET fiber by using modified silicon dioxide

A technology of silica and crystallization properties, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, and fire-resistant and flame-retardant filament manufacturing. It can solve the problems of not improving polymer properties, reducing polymer properties, and large specific surface area. Achieve the effect of improving crystallization performance and thermal performance, low cost and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

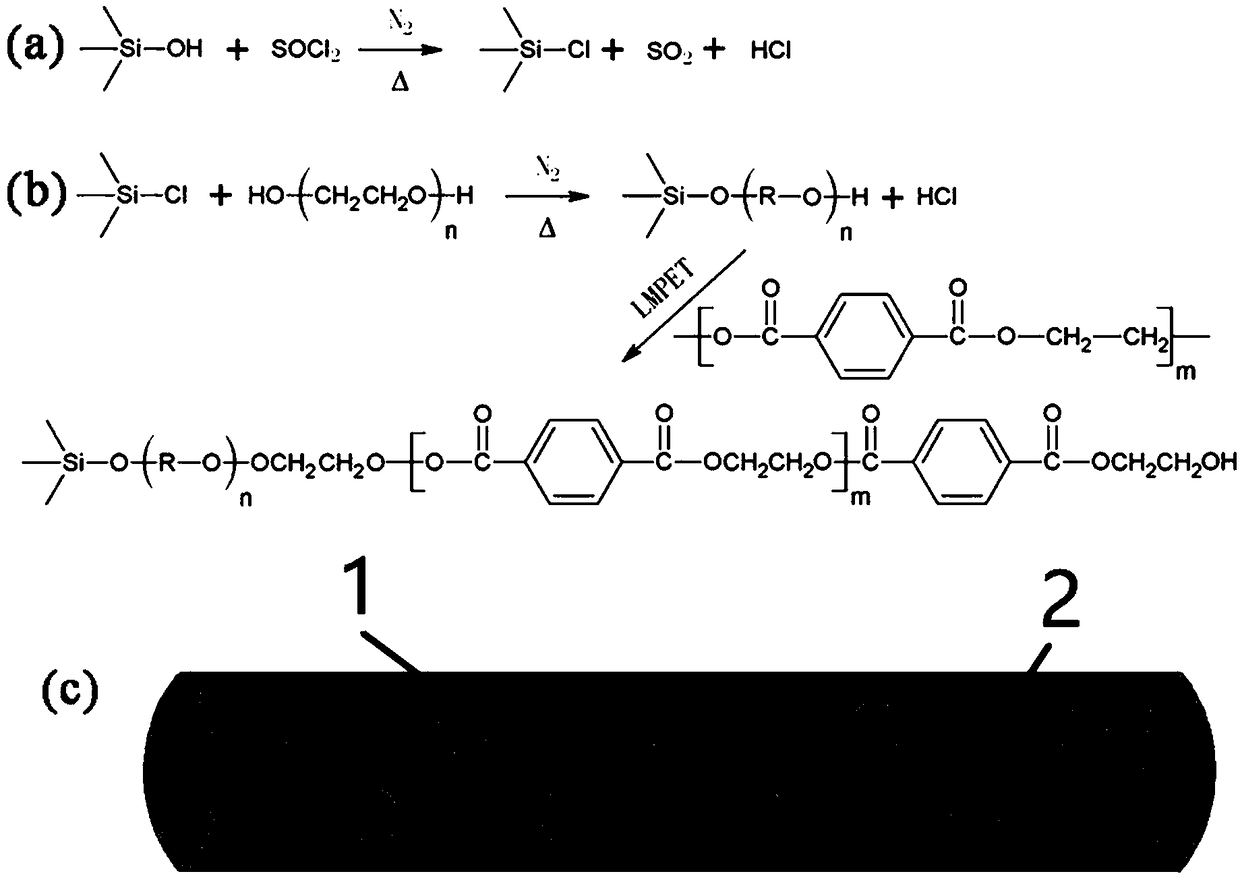

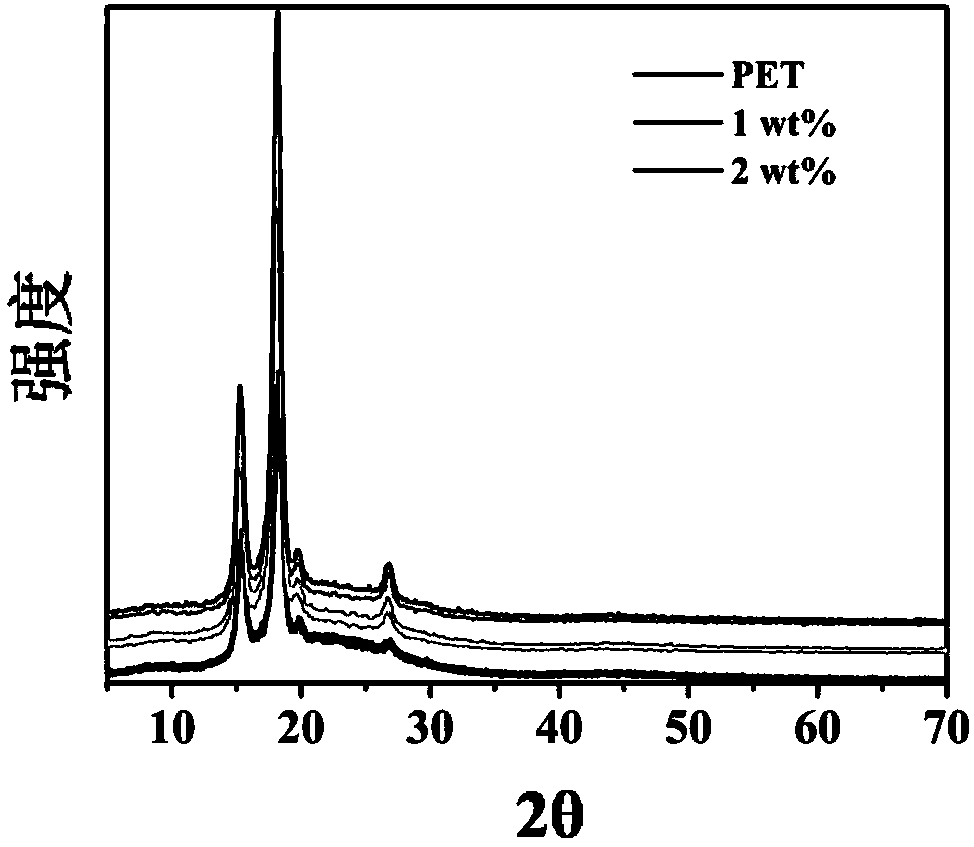

[0029] figure 1 It is the chemical equation for preparing modified silica nanoparticles and the structure schematic diagram of the obtained PET fiber in the present invention, wherein 1 is modified silica, and 2 is PET fiber. In the present embodiment, the method for improving the crystallization performance and thermal performance of PET fibers by using modified silica specifically includes the following steps:

[0030] Preparation of modified nano-silica: first, in benzene, under nitrogen protection, use thionyl chloride to pre-activate the surface of nano-silica, introduce chlorine atoms into the surface of the silica, wash 3 times with benzene, and centrifuge; then In toluene, under the protection of nitrogen, small molecule polyethylene glycol (PEG) was grafted onto the surface of chlorine-containing nano silicon dioxide (SiO 2 -PEG), washed twice with toluene and acetone, and dried by centrifugation; then in the solution of mass fraction phenol:tetrachloroethane=1:1, lo...

Embodiment 2

[0040] In the present embodiment, the method for improving the crystallization performance and thermal performance of PET fibers by using modified silica specifically includes the following steps:

[0041] Preparation of modified nano-silica: first, in benzene, under nitrogen protection, use thionyl chloride to pre-activate the surface of nano-silica, introduce chlorine atoms into the surface of the silica, wash 3 times with benzene, and centrifuge; then In toluene, under the protection of nitrogen, small molecule polypropylene glycol (PPG) was grafted onto the surface of chlorine-containing nano-silica (SiO 2 -PPG), washed twice with toluene and acetone, and centrifuged and dried; then in the solution of mass fraction phenol:tetrachloroethane=1:1, low molecular weight polyethylene terephthalate (LMPET ) grafted to the hydroxyl groups of the PPG segment to form SiO 2 -PPG-LMPET nanoparticles, that is, modified nano silicon dioxide.

[0042] Preparation of PET fiber by using ...

Embodiment 3

[0048] In the present embodiment, the method for improving the crystallization performance and thermal performance of PET fibers by using modified silica specifically includes the following steps:

[0049] Preparation of modified nano-silica: first, in benzene, under nitrogen protection, use thionyl chloride to pre-activate the surface of nano-silica, introduce chlorine atoms into the surface of the silica, wash 3 times with benzene, and centrifuge; then In toluene, under the protection of nitrogen, the polyether diol of small molecules is grafted onto the surface of chlorine-containing nano-silica (silicon dioxide-polyether diol), washed twice with toluene and acetone, and dried by centrifugation; Then in the solution of mass fraction phenol:tetrachloroethane=1:1, low molecular weight polyethylene terephthalate (LMPET) is grafted to the hydroxyl group of the polyether glycol chain segment to form carbon dioxide Silicon-polyether glycol-polyethylene terephthalate nanoparticles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com