Method for processing cyclohexane oxidation liquid

A technology of cyclohexane oxidation solution and cyclohexyl hydrogen peroxide, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. Weak, low effective utilization of active centers, etc., to achieve the effect of improving effective utilization, high alcohol-ketone ratio, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

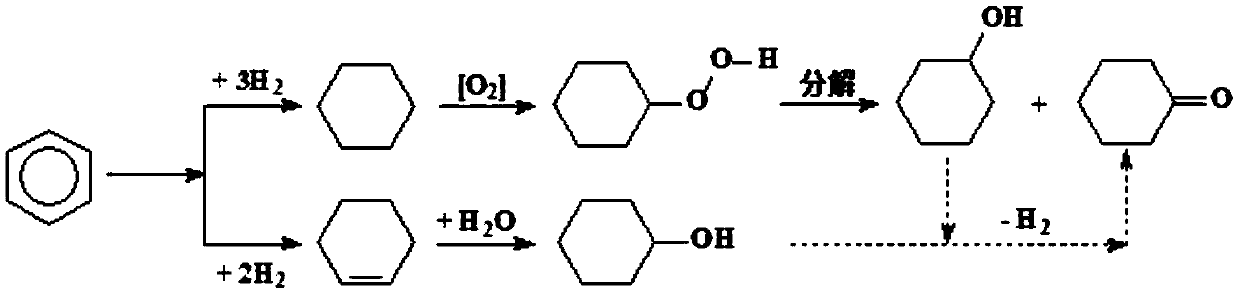

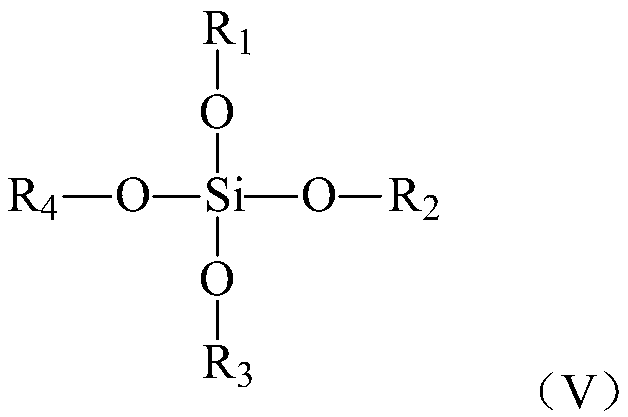

[0018] The invention provides a method for processing cyclohexane oxidation liquid, the method comprising: contacting cyclohexane oxidation liquid with a catalyst, the cyclohexane oxidation liquid contains cyclohexyl hydroperoxide, and the catalyst contains silicon-containing molecular sieve , the preparation method of the silicon-containing molecular sieve comprises: (1) hydrolyzing a silicon source, a Group VIII metal source, and a structure-directing agent to obtain a hydrolyzed material; (2) crystallizing the hydrolyzed material; wherein, the first The Group VIII metal source is an iron source or a mixture of an iron source and a cobalt source, step (1) is carried out in the presence of an organophosphorus compound and / or before step (2), the hydrolyzed material is mixed with an organophosphorus compound and then The crystallization is carried out.

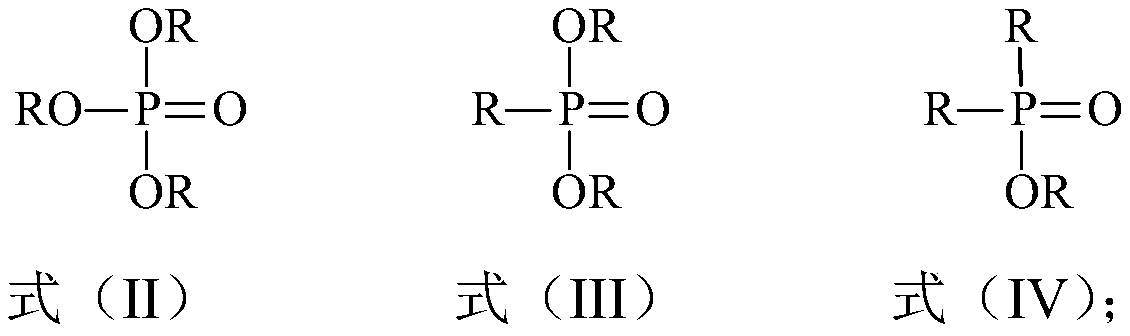

[0019] In the present invention, an organic phosphorus compound refers to a phosphorus-containing organic compound.

[0020...

Embodiment approach

[0022] According to a preferred embodiment of the present invention, the cyclohexane oxidation solution contains 3.0-3.6% by weight of cyclohexyl hydroperoxide, 0.6-1.0% by weight of cyclohexanol, 0.4-0.7% by weight of cyclohexanone, 0.15 - 0.3% by weight of organic acids, 0.2-0.4% by weight of organic esters, 94.00-95.65% by weight of cyclohexane.

[0023] According to the aforementioned technical scheme, the purpose of the present invention can be achieved. For the present invention, the molar ratio of the organic phosphorus compound to the silicon source is preferably P: SiO 2 =(0.001-0.5):1, more preferably P:SiO 2 =(0.1-0.3):1. Thus, the performance of the silicon-containing molecular sieve can be improved, for example, its catalytic decomposition performance used as a catalyst for processing cyclohexane oxidation liquid can be improved, the ratio of alcohol to ketone can be greatly improved, and the selectivity of alcohol to ketone can be high.

[0024] According to a ...

Embodiment 1

[0075] (1) hydrolyzing tetraethyl orthosilicate, ferric nitrate, tripropyl phosphate, tetrapropyl ammonium hydroxide aqueous solution (concentration: 25% by weight) to obtain hydrolyzed material; the temperature of hydrolysis is 30°C, and the time is 10h;

[0076] (2) The hydrolyzed material, tripropyl phosphate and methyltriethoxysilane are mixed and then transferred to a crystallization kettle for crystallization, wherein the mixing conditions include: the temperature is 70°C, the time is 4h, the crystallization The conditions for crystallization include: crystallization under autogenous pressure under airtight conditions, the temperature is 160°C, and the time is 24h;

[0077] Wherein, the consumption of the tripropyl phosphate in the step (1) and the step (2) is respectively 30% by weight and 70% by weight of the total consumption of the tripropylphosphate;

[0078] The molar ratio of each material feeding is SiO2: structure directing agent: Group VIII metal: H2O = 1: 0.05...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com