Preparing method of solar photovoltaic assembly glass surface composite film

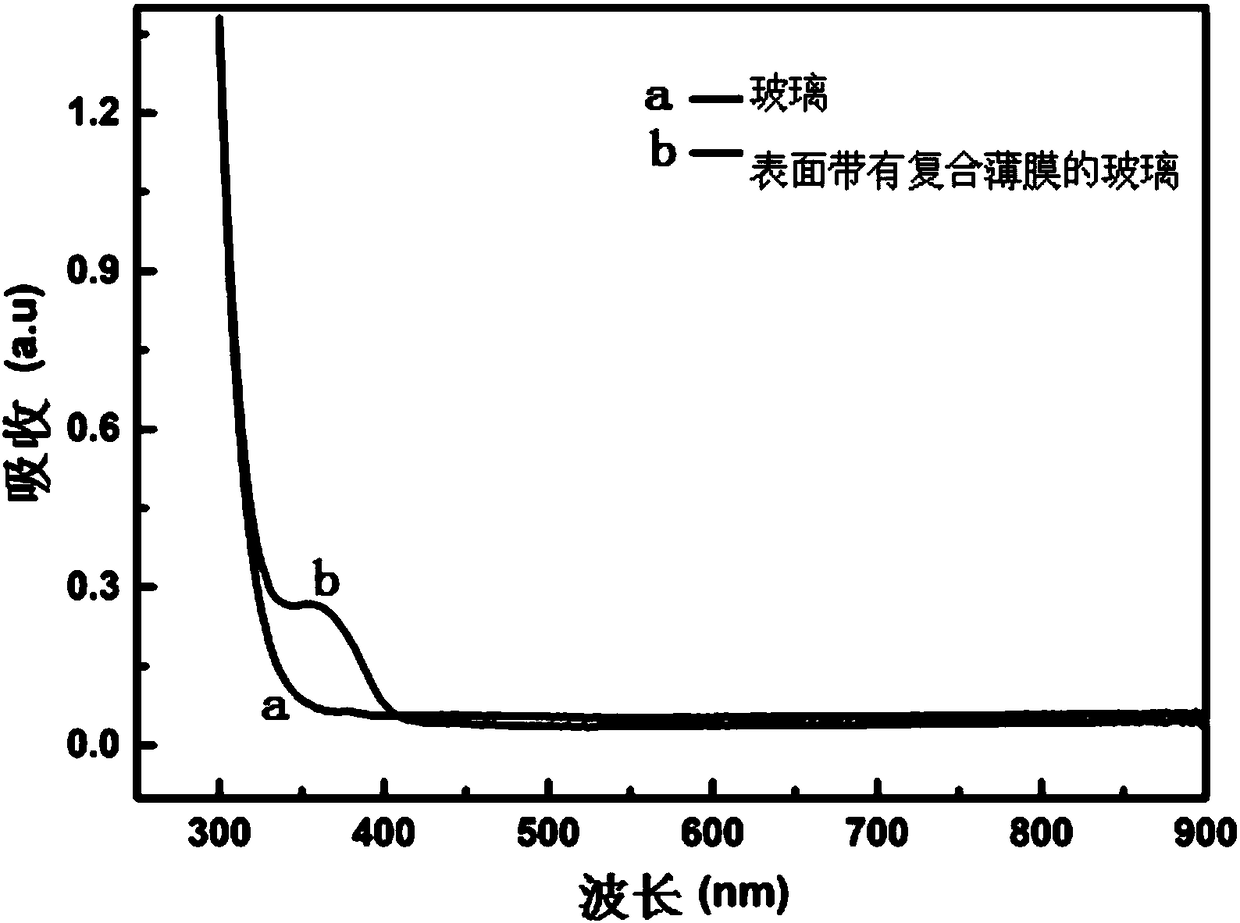

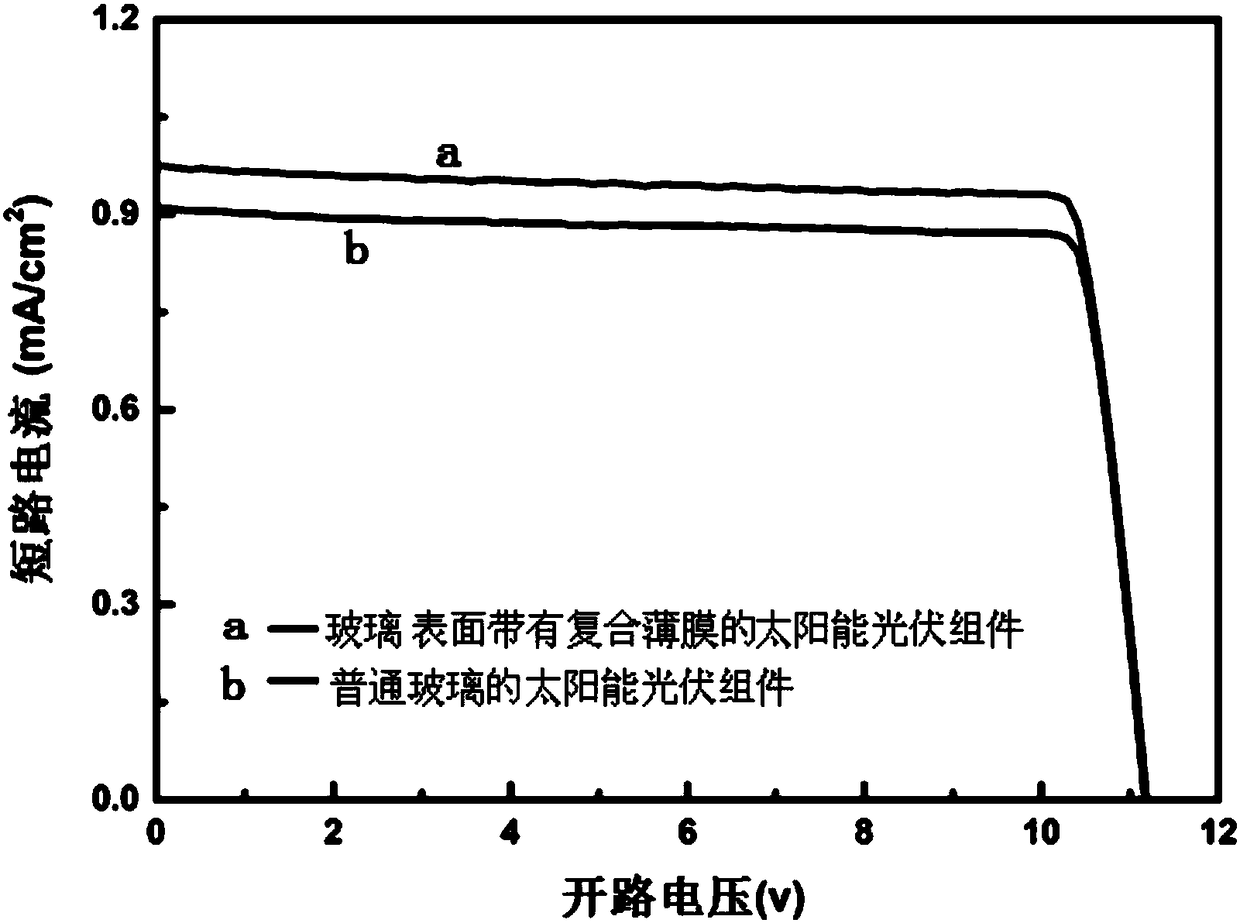

A solar photovoltaic, glass surface technology, applied in photovoltaic power generation, semiconductor/solid-state device manufacturing, electrical components and other directions, can solve the problems of poor transparency, high cost, poor utilization of ultraviolet light of composite materials, etc., to improve photovoltaic conversion efficiency, dispersion Good performance, improve the effect of photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment one: the preparation method of the composite film on the glass surface of the solar photovoltaic module of the present embodiment is carried out according to the following steps:

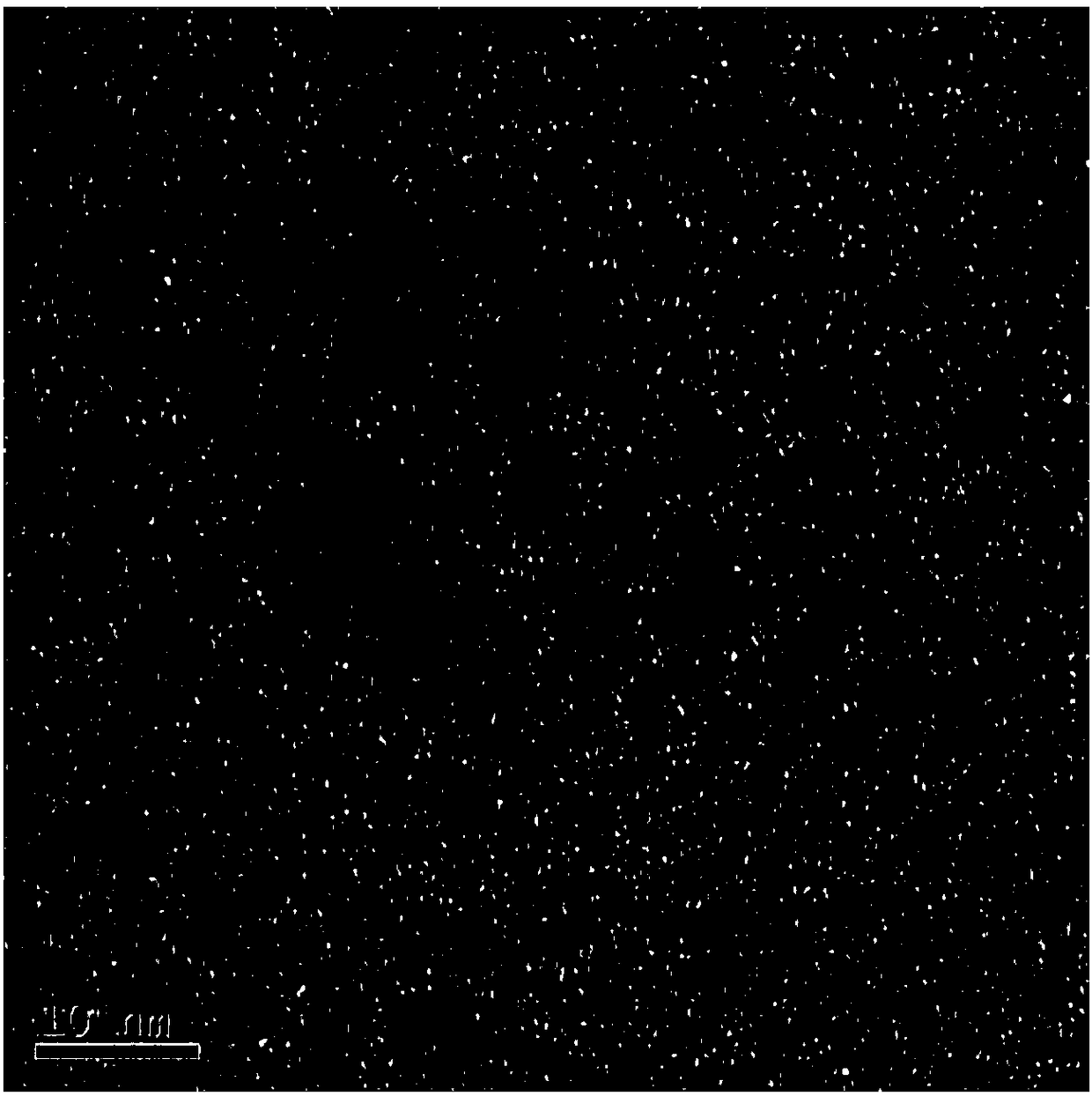

[0022] 1. Preparation of carbon quantum dot solution: Prepare an aqueous solution according to the mass concentration of the carbon source at 5-200g / L, then add a silane coupling agent and mix evenly to obtain a precursor solution; Hydrothermal reaction at 160-300°C for 5-20 hours, extraction and dialysis of the mixed liquid obtained after the hydrothermal reaction, to obtain a carbon quantum dot solution;

[0023] 2. Preparation of silica sol: Mix the silica sol precursor, absolute ethanol and deionized water at room temperature, adjust the pH to 2.5-6.5 with acid, then stir, evaporate, and age to obtain the silica sol solution; The silica sol precursor is an organic silica sol precursor or an inorganic silica sol precursor;

[0024] Three, the configuration of sol for c...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the carbon source is one or both of glucose and citric acid; the others are the same as Embodiment 1.

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: in step one, the silane coupling agent is one or more combinations of KH570, KH585, KH792; other and specific implementation Way 1 or 2 are the same.

[0028] In this embodiment, the silane coupling agent contains a nitrogen-hydrogen bond or a sulfhydryl bond to passivate the carbon quantum dots.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com