Sewage treatment agent and preparation method thereof

A technology of sewage treatment agent and solvent, which is applied in water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamic water/sewage treatment, etc. It can solve the problem of poor treatment effect of physical methods and cost of biological treatment High, complex process and other problems, to achieve good stability, good anti-color effect, and enhance the effect of adsorption bridging structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

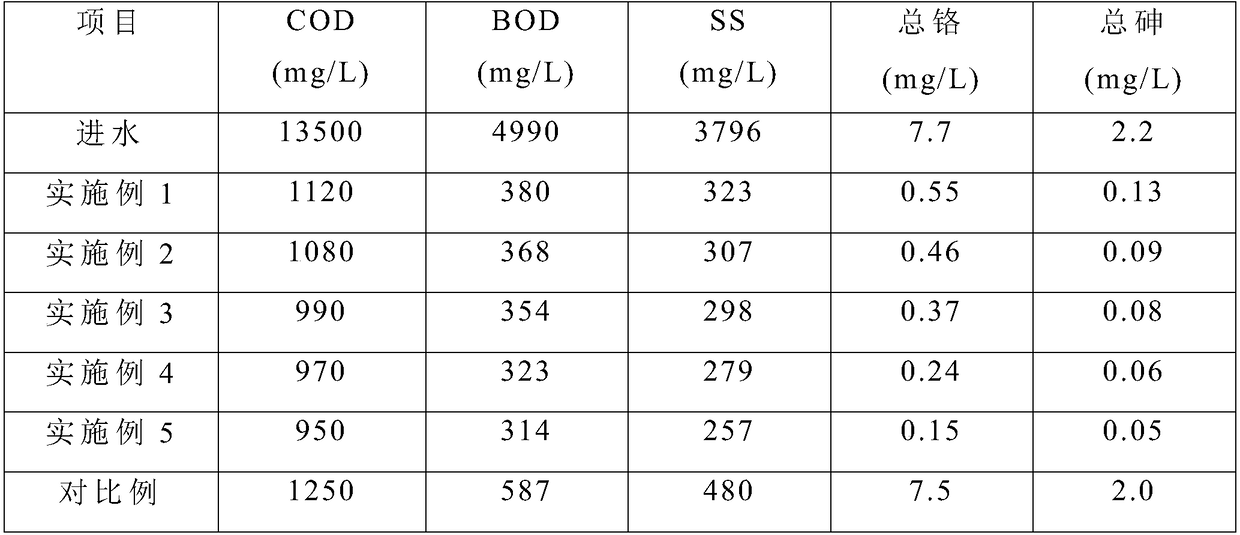

Examples

Embodiment 1

[0034] A preparation method of sewage treatment agent, comprising the steps of:

[0035] 1) Surface modification of polymeric aluminum iron silicate: add 30 g of polymeric aluminum iron silicate to 100 g of ethanol, then add 15 g of 3-chloropropyltriethoxysilane, stir and react at 40 ° C for 6 hours, and remove the solvent by rotary evaporation can;

[0036] 2) Amino starch-modified surface-modified polyaluminum iron silicate: add 30 g of the surface-modified polyaluminum iron silicate prepared in step 1) into 100 g of isopropanol, and add 10 g of amino starch to it, and stir at 40°C Reacted for 4 hours, and the solvent was removed by rotary evaporation;

[0037] 3) Dimethyl-vinyl phosphate transesterification: Add 30 g of amino starch modified surface-modified polyaluminum iron silicate prepared in step 2) into 100 g of acetone, then add 15 g of dimethyl-vinyl phosphate, KOH 5g and 5g of chloranil, react at 70°C for 10 hours, then filter, wash with water for 3 times, absorb...

Embodiment 2

[0042] A preparation method of sewage treatment agent, comprising the steps of:

[0043]1) Surface modification of polyaluminum iron silicate: add 35 g of polyaluminum iron silicate into 110 g of isopropanol, then add 18 g of 3-chloropropyltriethoxysilane, stir and react at 42°C for 6.5 hours, and spin evaporate Just remove the solvent;

[0044] 2) Amino starch-modified surface-modified polyaluminum iron silicate: add 35 g of the surface-modified polyaluminum iron silicate prepared in step 1) into 115 g of isopropanol, and add 13 g of amino starch to it, and stir at 45°C Reacted for 4.5 hours, and the solvent was removed by rotary evaporation;

[0045] 3) Dimethyl-vinyl phosphate transesterification: add 35 g of amino starch modified surface-modified polyaluminum iron silicate prepared in step 2) into 115 g of acetone, then add 17 g of dimethyl-vinyl phosphate, NaOH 6g and 6.5g of l,4-naphthoquinone were reacted at 75°C for 10.5 hours, then filtered, washed with water for 4 ...

Embodiment 3

[0050] A preparation method of sewage treatment agent, comprising the steps of:

[0051] 1) Surface modification of polyaluminum iron silicate: add 40 g of polyaluminum iron silicate to 135 g of n-butanol, then add 20 g of 3-chloropropyltriethoxysilane, stir and react at 45 °C for 7 hours, and spin evaporate Just remove the solvent;

[0052] 2) Amino starch-modified surface-modified polyaluminum iron silicate: add 40 g of the surface-modified polyaluminum iron silicate prepared in step 1) into 136 g of isopropanol, and add 15 g of amino starch to it, and stir at 48°C Reacted for 5 hours, and the solvent was removed by rotary evaporation;

[0053] 3) Dimethyl-vinyl phosphate transesterification: add 40 g of amino starch modified surface-modified polyaluminum iron silicate prepared in step 2) into 130 g of acetone, then add 20 g of dimethyl-vinyl phosphate, NaOCH 3 7.5g and 8g of chloranil were reacted at 80°C for 11 hours, then filtered, washed with water for 5 times, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com