Method for improving yield of glycolic acid in Escherichia coli

A technology of Escherichia coli and glycolic acid, applied in the field of bioengineering, can solve the problems of limited growth of bacteria and accumulation of acetic acid, and achieve the effect of reducing the accumulation of acetic acid and increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

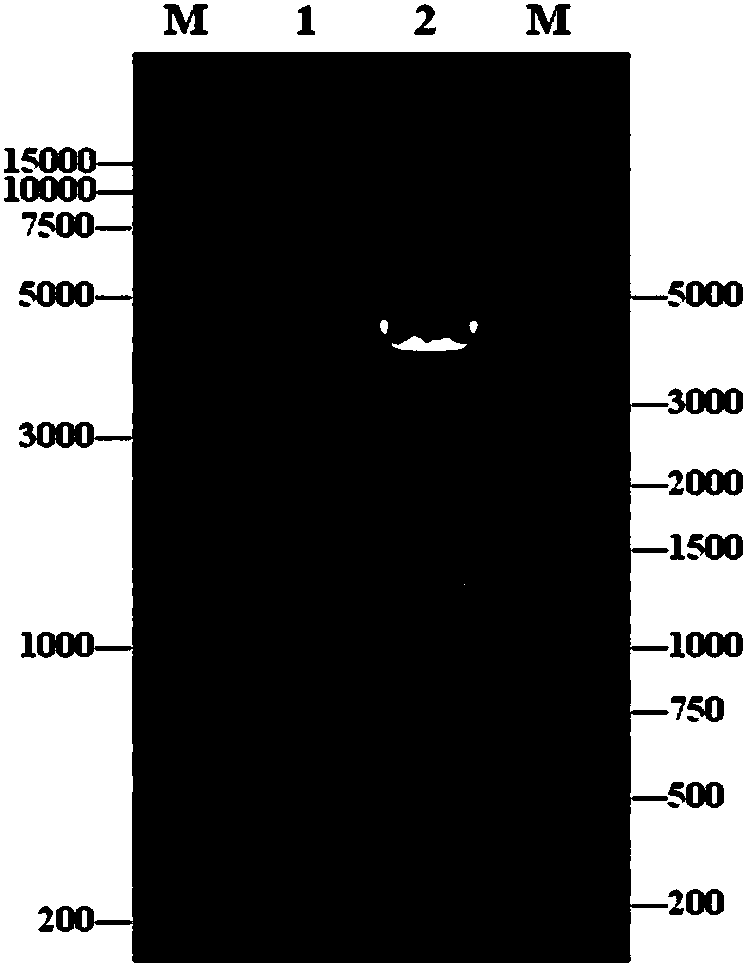

[0023] Example 1: Construction of recombinant plasmid pJNU-5 and acquisition of recombinant strains

[0024] Using Escherichia coli MG1655(DE3) genome as template to amplify target gene gltA by PCR

[0025] (pJNU-5F:TTAGGATCCAAGGAGATATAATGGCTGATACAAAAGCAAA, pJNU-5R:CGCAAGCTTTTAACGCTTGATATCGCTTTTA).

[0026] BamH I and Hind III double-digested the PCR-amplified gene fragment at 37°C for 2 hours, purified it with a PCR product purification kit, BamH I and Hind III double-digested plasmid pCDFDuet-1 at 37°C for two hours, and recovered the vector fragment with a gel recovery kit. T4 ligase to treat the target gene fragment and the carrier fragment, and treat at 16°C for 8-10 hours, add the above ligation reaction solution to 100 μL Escherichia coli JM109 transformation competent medium, place on ice for 30min, heat shock at 42°C for 90s, add 1mL LB liquid culture base, incubated at 37°C for 1 h on a shaker, and coated with streptomycin-resistant plates (50 mg / L). After culturin...

Embodiment 2

[0027] Embodiment 2: Construction of recombinant plasmid pJNU-4

[0028] The plasmid pTrc99A was digested with EcoR I and BamHI to obtain the vector fragment. EcoR I and BamHI double digestion plasmid pGLY-2 (disclosed in Dhamankar, H.; Tarasova, Y.; Martin, C.H.; Prather, K.L., Engineering E. coli for the biosynthesis of 3-hydroxy-γ-butyrolactone (3HBL) and 3,4-dihydroxybutyric acid (3,4-DHBA) as value-added chemicals from glucose as asole carbon source. Metabolic Engineering 2014, 25, 72-81.), to obtain the target gene (ycdW, aceAK) fragment. T4 ligase to treat the target gene fragment and the carrier fragment, and treat at 16°C for 8-10 hours, add the above ligation reaction solution to 100 μL Escherichia coli JM109 transformation competent medium, place on ice for 30min, heat shock at 42°C for 90s, add 1mL LB liquid culture base, incubated at 37°C for 1 h on a shaker, and coated with ampicillin-resistant plates (100 mg / L). The positive clones were picked for verification...

Embodiment 3

[0029] Example 3: Knockout of lactate dehydrogenase gene ldhA in MG1655 (DE3)

[0030] ldhA (lactate dehydrogenase) was knocked out by λ-Red recombinant method. The specific implementation steps are as follows. Using pKD4 as a template, using primer ko-ldhA F:

[0031] GTGTAGGCTGGAGCTGCTTC,ko-ldhA

[0032] R: ATGGGAATTAGCCATGGTCC amplifies the knockout frame, which contains 39 bp of homology arms at both ends of the target gene, two FRT sites and the Kana resistance gene. The MG1655 (DE3) strain transformed with pKD46 was inoculated in LB medium, cultivated overnight at 30°C, and then transferred to 50mL LB medium with a 1% inoculum size, while adding 100mg / L ampicillin and 10mM arabinose, 30 Cultivate to OD 600 =0.4~0.6, the three proteins on pKD46 can be fully expressed. Pre-cool on ice for 30 minutes, collect the bacteria by centrifugation at 5000r / min, then wash once with sterile water and twice with 10% glycerol, concentrate the final bacteria into 500 μL compete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com