Method for continuously extracting and purifying ginger polyphenol

A technology of ginger and combined extraction, used in agriculture and light industry, can solve the problems of high maintenance requirements, low extraction efficiency of phenolic substances, and large solvent consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0053] Experimental example: selection of process parameters

[0054] The raw material used in this experiment is Anqiu ginger provided by Shandong Datang Biotechnology Co., Ltd.

[0055] (1) Selection of enzymatic extraction process

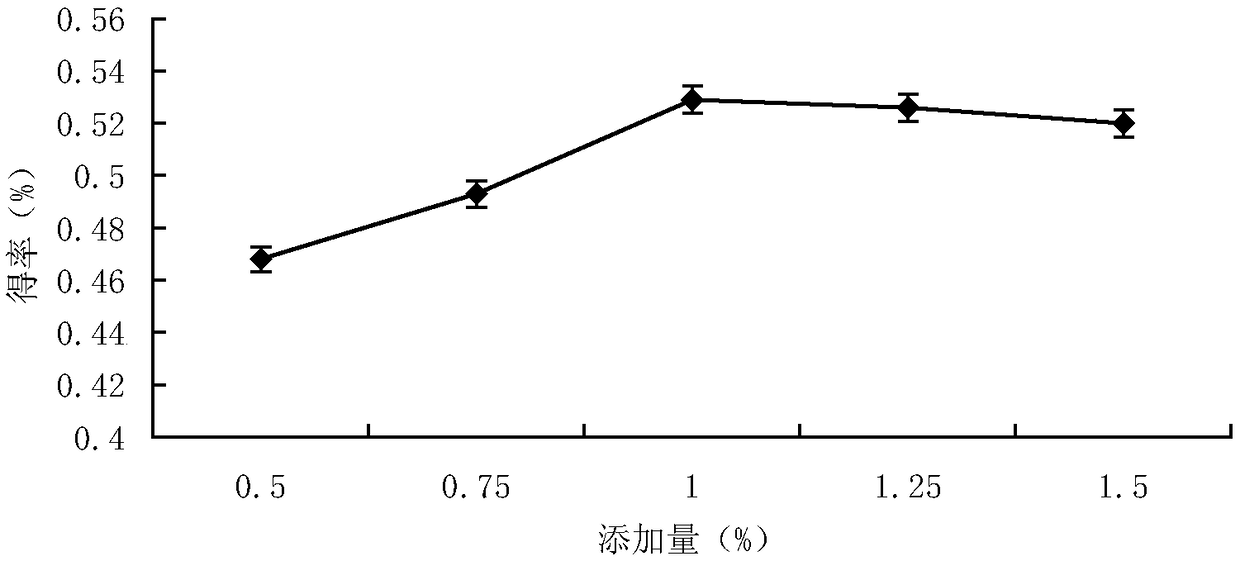

[0056] ① Enzyme dosage selection

[0057] According to experiments, when the amount of cellulase added is between 0.5% and 1%, the yield of polyphenols increases with the increase of enzyme amount, and reaches the maximum value at 1%. After more than 1%, the yield basically remained the same, and the difference was not significant. Such as figure 1 shown. Therefore, the optimal amount is 1%.

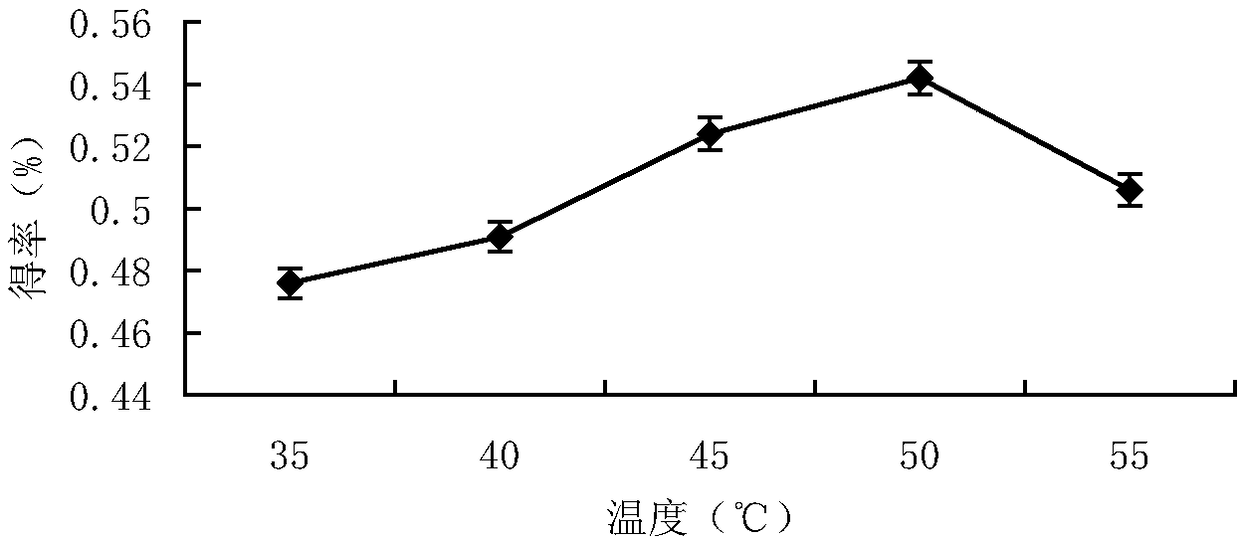

[0058] ②Enzymolysis temperature selection

[0059] According to experiments, within 50°C, as the temperature increases, the yield of polyphenols increases gradually, and reaches the maximum at 50°C. After 50°C, the yield gradually decreased with the increase of temperature. Such as figure 2 shown. Therefore, the optimum enzymatic hydrolysis temp...

Embodiment

[0168] Embodiment: the preparation of ginger polyphenol

[0169] Add 1g cellulase according to every 100g shredded ginger, enzymolysis 50min at 35°C, collect the supernatant, add 2 times (mass: volume) 80% ethanol solvent to the remaining ginger slag, and ultrasonically extract twice under 400W power. After 1.5 hours, the supernatants were collected twice and combined, and the yield of ginger polyphenols extracted by the enzyme-ultrasonic method was 0.551%;

[0170] Adjust the concentration of ginger polyphenols in the supernatant extracted by enzyme-ultrasonic method to 0.5mg / mL, and perform ultrafiltration purification. The conditions are 30KD ultrafiltration membrane, 30°C, 0.15MPa pressure, and the membrane flux is 33.34mL *m -2 *s -1 , collect the ultra-filtered ginger polyphenol liquid less than 30KD;

[0171] The ultrafiltration ginger polyphenol solution was purified by the AB-8 macroporous resin adsorption method. The static adsorption conditions were: the optimal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com