Microcapsule for self-repairing of cement-based micro-cracks and preparation method of microcapsule

A microcapsule self-repair technology, applied in the field of waterproof building materials, can solve problems such as lack of repair agent, failure of microcapsule capsule wall, and influence on self-repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

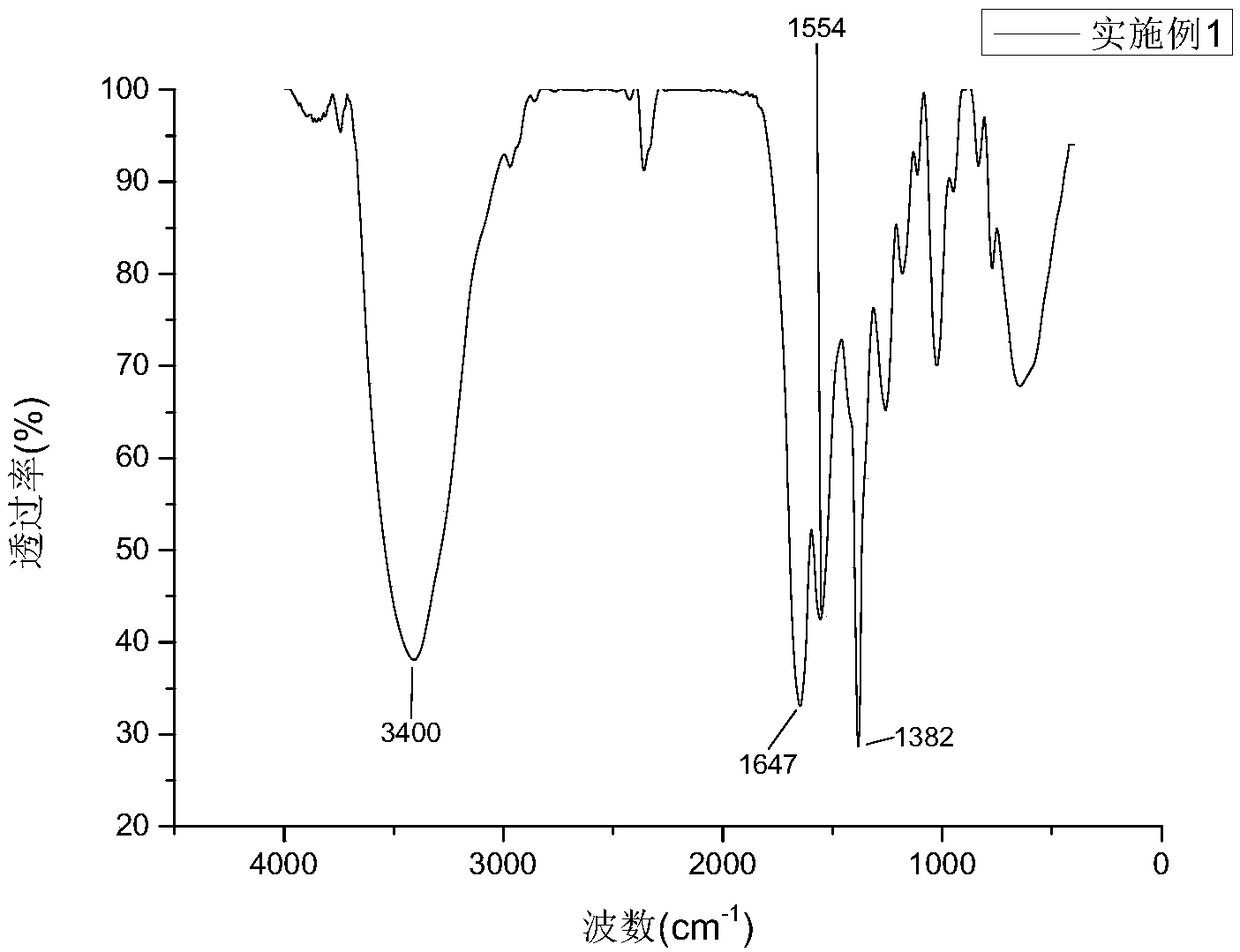

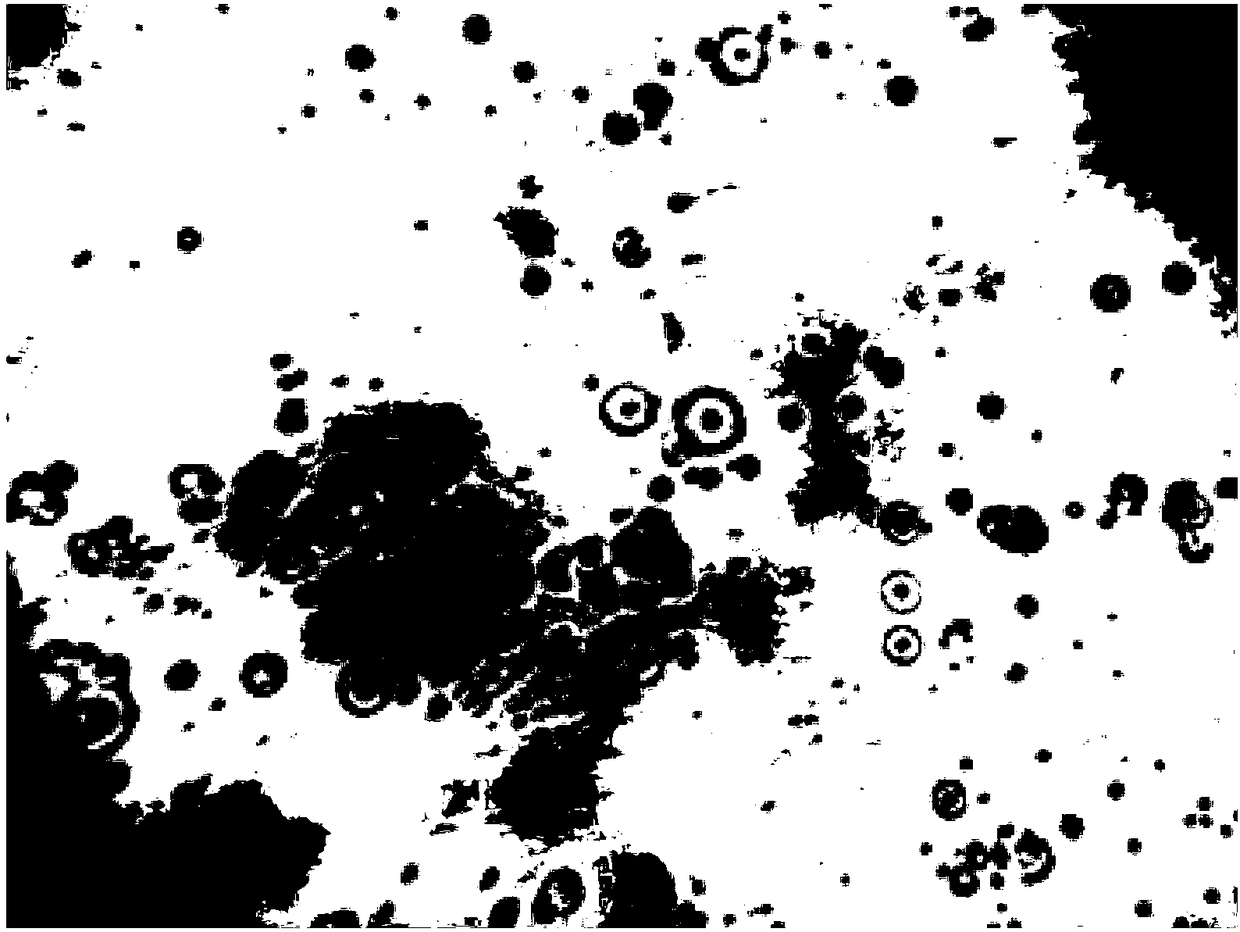

Embodiment 1

[0036] First put 13.5g of 37% formaldehyde solution, 5g of urea, and 0g of water in a reaction vessel with a mechanical stirring device and stir evenly, then add sodium hydroxide to adjust the pH to 8.0, and keep stirring at 50°C Heating in a constant temperature water bath for 1 hour to form a urea-formaldehyde resin prepolymer, and cooling to room temperature;

[0037] Then put the cooled urea-formaldehyde resin prepolymer with 5g of calcium nitrate, 0.8g of Span 80, 0.5g of resorcinol, and 0.5g of ammonium chloride in a reaction vessel and mix them evenly, and mix them evenly at 50°C while stirring. Heating in a constant temperature water bath for 40 minutes to obtain an emulsion;

[0038] Slowly add sulfurous acid dropwise to the emulsion to adjust the pH of the system to 2.0, and heat in a constant temperature water bath at 50°C for 1.5 hours while stirring;

[0039] Then heat up to 60°C, and heat in a constant temperature water bath for 1 hour while stirring to obtain a...

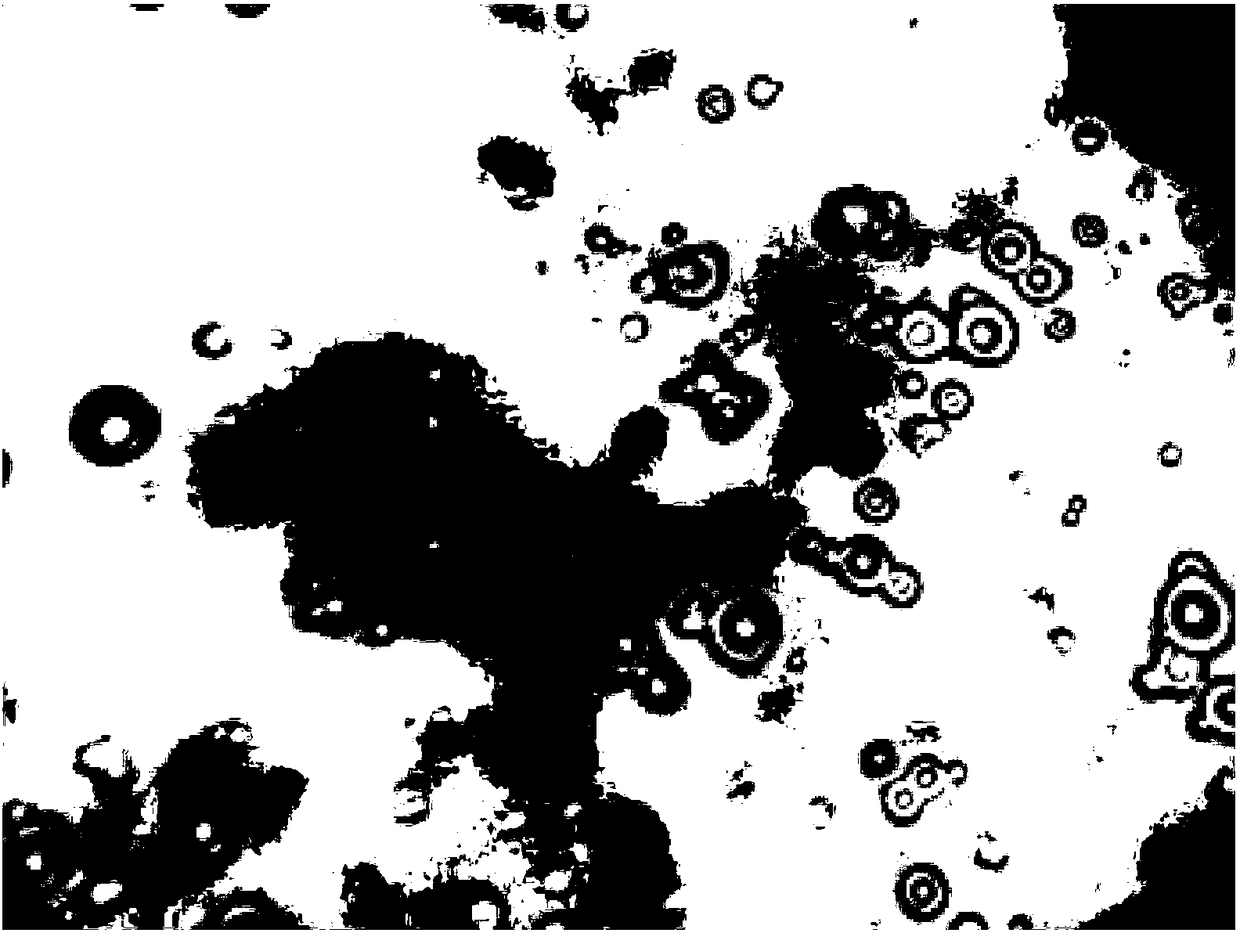

Embodiment 2

[0049] Put 12g of 37% formaldehyde solution, 4.5g of urea, and 2g of water in a reaction vessel with a mechanical stirring device and stir evenly, then add triethanolamine to adjust the pH to 8.0, and heat it in a constant temperature water bath at 55°C while stirring 1h, form urea-formaldehyde resin prepolymer, cool to room temperature;

[0050] Put the cooled urea-formaldehyde resin prepolymer and the aqueous solution of 5g sodium silicate, 0.8g Tween 80, 0.4g hydroquinone, 0.6g polyethylene glycol in the reaction vessel and mix evenly, stir while stirring at 55 Heating in a constant temperature water bath at ℃ for 1 hour to obtain an emulsion;

[0051] Slowly add acetic acid dropwise to the emulsion to adjust the pH of the system to 2.5, and heat in a constant temperature water bath at 55°C for 1.5 hours while stirring;

[0052] Then heat up to 65°C, and heat in a constant temperature water bath for 1 hour while stirring to obtain a suspension, at which time the capsule wa...

Embodiment 3

[0057] First put the mixture of 15g37% formaldehyde solution, 5.5g urea and 5g water in a reaction vessel with a mechanical stirring device and stir evenly, add ammonia water to adjust the pH to 8.5, and heat it in a constant temperature water bath at 50°C for 1 hour while stirring , forming a urea-formaldehyde resin prepolymer, cooled to room temperature;

[0058] Then put the cooled urea-formaldehyde resin prepolymer and 6g of sodium metaaluminate, 0.5g of sodium dodecylbenzene sulfonate, 0.4g of polypropylene glycol, and 0.5g of ammonium chloride in a reaction vessel and mix evenly while stirring While heating in a constant temperature water bath at 50°C for 50 minutes, an emulsion was obtained;

[0059] Slowly add sulfuric acid dropwise to the emulsion to adjust the pH of the system to 3.0, and heat in a constant temperature water bath at 50°C for 1.5 hours while stirring;

[0060] Then heat up to 60°C, and heat in a constant temperature water bath for 1.5 hours while sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com