Treatment agent for oily wastewater and preparation method of treatment agent

A technology for treating chemicals and wastewater, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. The effect of a wide range of sources and a small amount of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

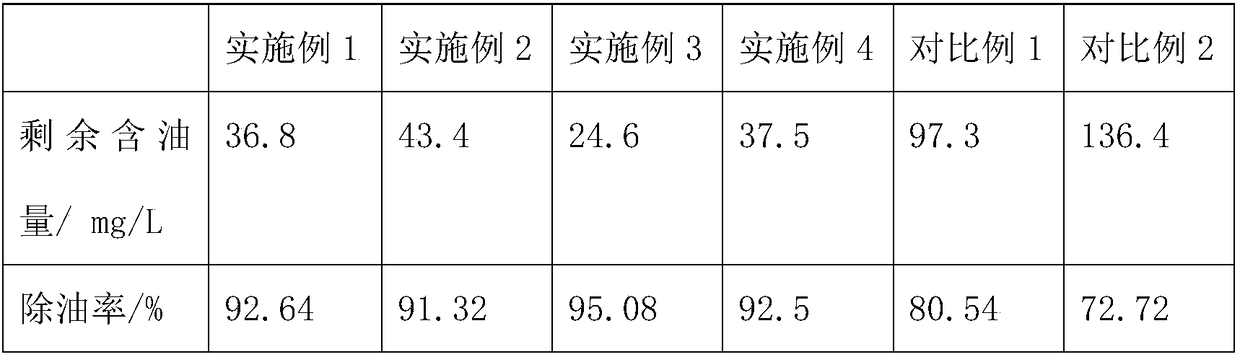

Examples

Embodiment 1

[0021] A treatment agent for oily wastewater, comprising the following raw materials in parts by weight: 6 parts of bentonite, 5 parts of vermiculite powder, 4 parts of polyvinyl alcohol, 1.3 parts of formamide, 3 parts of gelatin, 15 parts of pansy, and 6 parts of nano-graphene , 3 parts of magnetite slag, 2.4 parts of fruit tannin and 3.5 parts of tartaric acid. The particle diameter of the nano-graphene is 28nm, and the particle diameter of the vermiculite powder is 0.12mm.

[0022] The preparation method of the treatment agent of the oily wastewater, the specific steps are as follows:

[0023] Step 1, adding bentonite to 66% ethanol aqueous solution with a mass fraction of 4 times its weight and magnetically stirring evenly, adding the product into a muffle furnace and stirring and heating at 168 degrees Celsius for 90 minutes, and obtaining the first mixture after cooling;

[0024] Step 2, the pansy is expanded by low-temperature air flow, then extracted by supercritical...

Embodiment 2

[0030] A treatment agent for oily wastewater, comprising the following raw materials in parts by weight: 8 parts of bentonite, 7.5 parts of vermiculite powder, 4.8 parts of polyvinyl alcohol, 1.9 parts of formamide, 4 parts of gelatin, 18 parts of pansy, and 6.6 parts of nano-graphene , 3.5 parts of magnetite slag, 2.8 parts of fruit tannin and 4 parts of tartaric acid. Fruit tannins include blends of apple tannins, pomegranate tannins, and grape tannins.

[0031] The preparation method of the treatment agent of the oily wastewater, the specific steps are as follows:

[0032] Step 1, adding bentonite to 72% ethanol aqueous solution with a mass fraction 3 times its weight and magnetically stirring evenly, adding the product into a muffle furnace and stirring and heating at 166 degrees Celsius for 96 minutes, and obtaining the first mixture after cooling;

[0033] Step 2, the pansy is expanded by low-temperature air flow, then extracted by supercritical carbon dioxide extractio...

Embodiment 3

[0039] A treatment agent for oily wastewater, comprising the following raw materials in parts by weight: 11 parts of bentonite, 9.2 parts of vermiculite powder, 5.5 parts of polyvinyl alcohol, 2.4 parts of formamide, 4.8 parts of gelatin, 20 parts of pansy, and 7.4 parts of nano-graphene , 4.4 parts of magnetite slag, 3.6 parts of fruit tannin and 4.7 parts of tartaric acid. The particle diameter of the graphene nanometer is 36nm, and the particle diameter of the vermiculite powder is 0.1mm.

[0040] The preparation method of the treatment agent of the oily wastewater, the specific steps are as follows:

[0041] Step 1, adding bentonite to 70% ethanol aqueous solution with a mass fraction 5 times its weight and magnetically stirring evenly, adding the product into a muffle furnace and stirring and heating at 168 degrees Celsius for 105 minutes, and obtaining the first mixture after cooling;

[0042] Step 2, the pansy is expanded by low-temperature air flow, then extracted by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com