Doped metal diamond-like coating preparation method and its products

A technology of diamond coating and diamond layer, which is applied in metal material coating process, coating, vacuum evaporation plating, etc., can solve the problems of low atomic energy, low DLC percentage, low ionization rate, etc., to improve gas ionization The effect of increasing the ionization rate, improving production efficiency, and increasing the ionization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

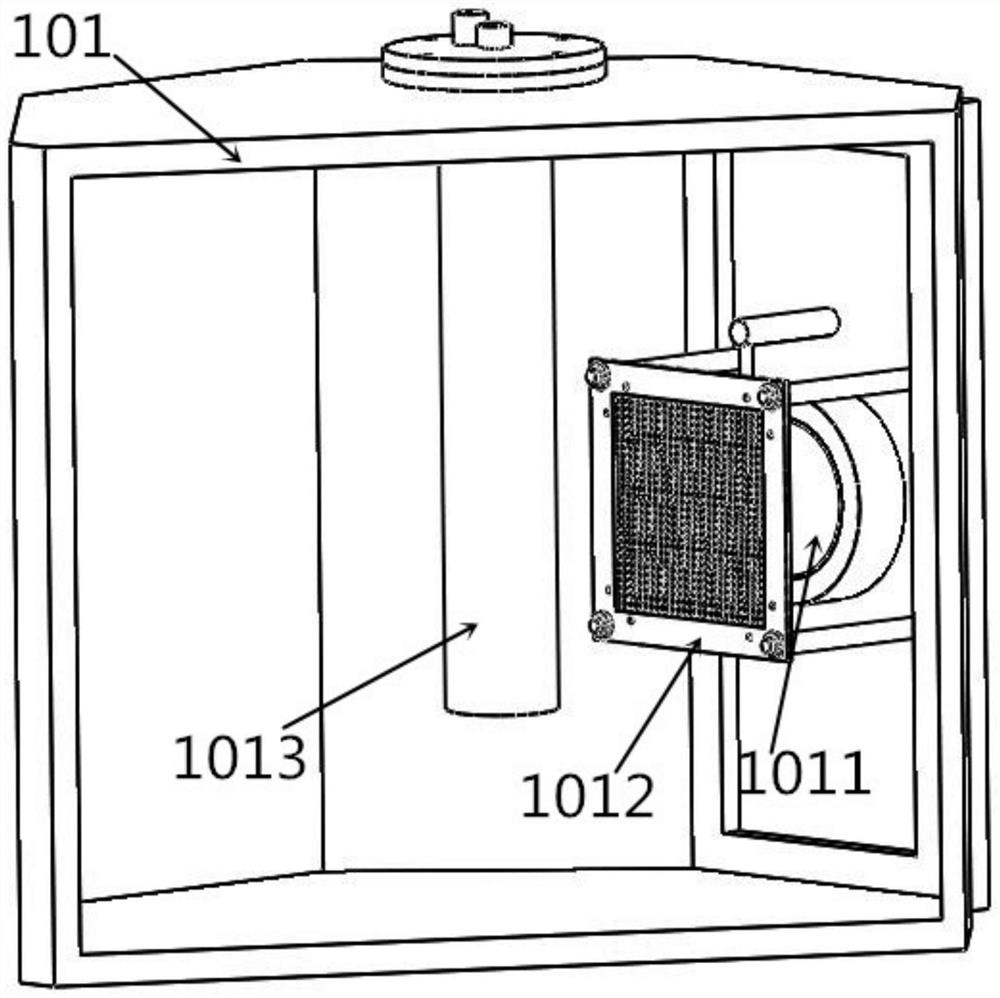

[0044] see figure 2 As shown: the arc ion plating equipment 101 for preparing the doped diamond-like coating of the present invention needs to add a gauze baffle plate 1012 with a suspended potential and a water-cooled anode 1013 on the basis of the original arc source 1011; Among them, the gauze baffle with suspended potential can filter out large particles. When the water-cooled anode is connected, the electrons in the discharge process of the arc source will be influenced by the electric field, and will be attracted to the water-cooled anode. Hydrocarbon gas collides to ionize the gas and efficiently produce diamond-like coatings; in addition, the metal atoms filtered by the gauze can change the ratio of doped metals to form gradients during the diamond-like deposition process by adjusting the arc current. Conducive to the surface properties of diamond-like coatings.

[0045] Explanation: Due to drawing needs, the gauze schematic diagram presented is an effect diagram, an...

Embodiment 2

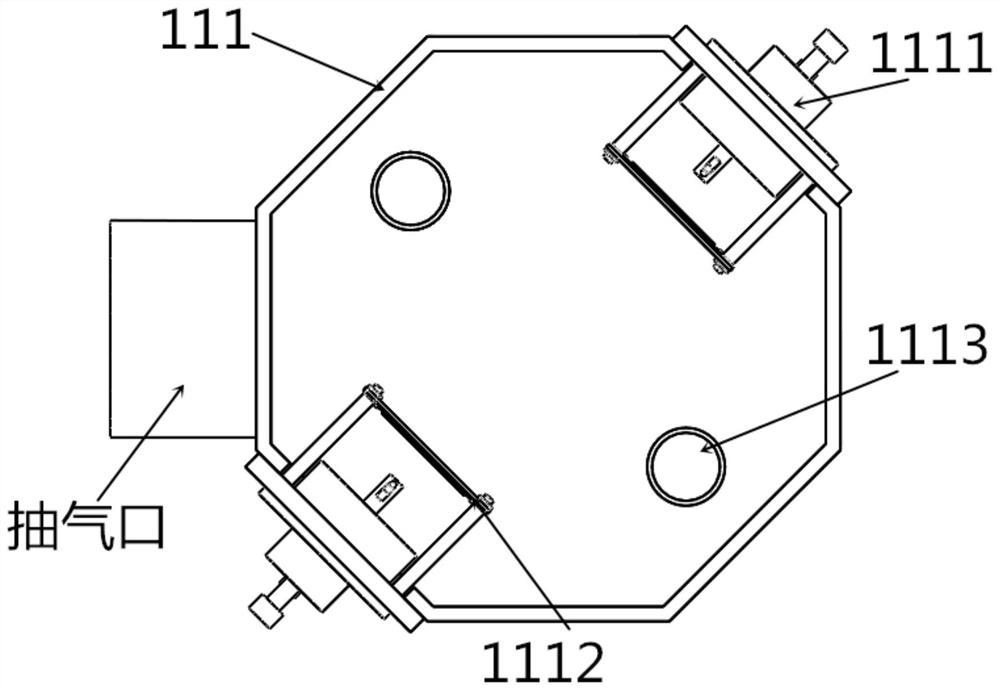

[0057] see figure 2 As shown: the arc ion plating equipment 111 for preparing the doped diamond-like coating of the present invention needs to add two gauze baffles 1112 with suspended potential and two water-cooled anodes 1113 on the basis of the original two sets of arc sources 1111; During the arc source discharge process, the gauze baffle with suspended potential can filter out large particles. When the water-cooled anode is connected, the electrons in the arc source discharge process will be influenced by the electric field and be attracted to the water-cooled anodes on both sides. During the electron movement, there will be hydrocarbon gas collisions, which will ionize the gas and efficiently produce diamond-like coatings; in addition, the metal atoms filtered by the gauze can be adjusted by arc current during the diamond-like deposition process to change the doping. The proportion of heterometals, forming a gradient, is beneficial to the surface properties of the diamo...

Embodiment 3

[0068] see Figure 4 Shown: the arc ion plating equipment 121 for preparing the doped diamond-like coating of the present invention needs to add four gauze baffles 1212 with suspended potential on the basis of the original four sets of arc sources 1211 and place a Water-cooled anode 1213; during the arc source discharge process, the gauze baffle with suspended potential can filter out large particles. When the water-cooled anode is connected, the electrons in the arc source discharge process will be influenced by the electric field and be attracted to the central position. On the water-cooled anode, in the process of electron movement, there will be hydrocarbon gas collisions, thereby ionizing the gas, and efficiently producing diamond-like coatings; in addition, the metal atoms filtered by the gauze can pass through the arc current during the diamond-like deposition process. Adjusting, changing the ratio of doped metals, forming a gradient, is beneficial to the surface proper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com