Preparation method of hydrophilic phenolphthalein polyethersulfone composite nanofiber ultrafiltration membrane

A technology of composite nanofibers and nanofiber membranes, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems that the hydrophilic modification of PES-C nanofiber composite ultrafiltration membranes is rarely mentioned, etc. Wide range of applications, improved hydrophobicity, and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

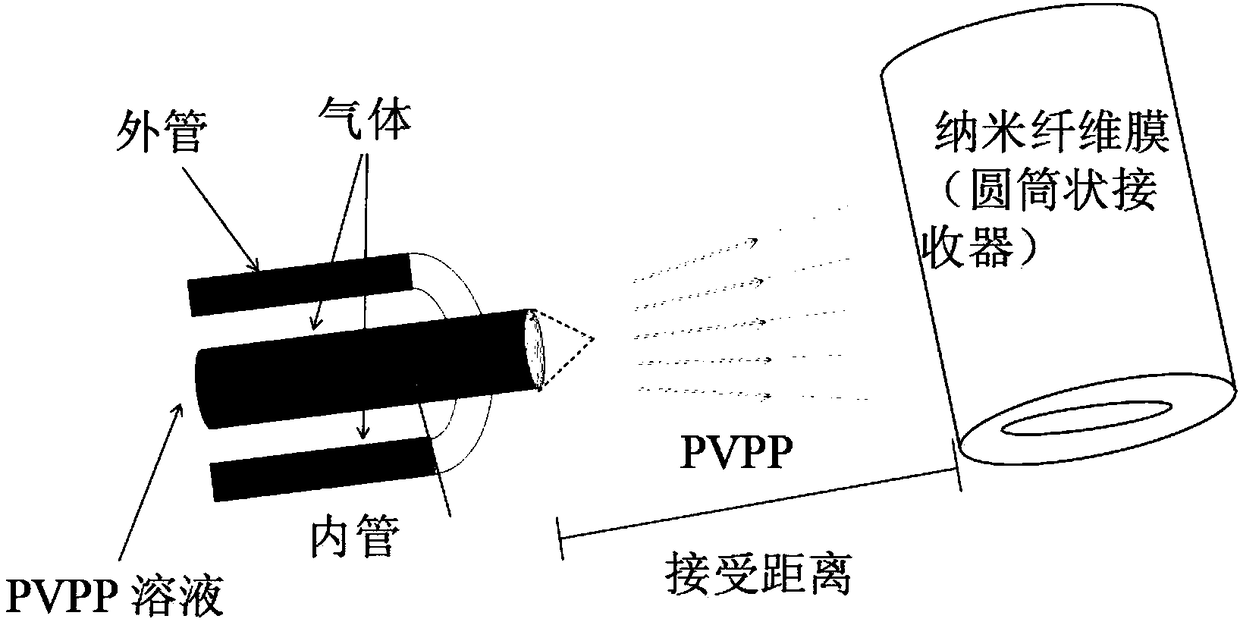

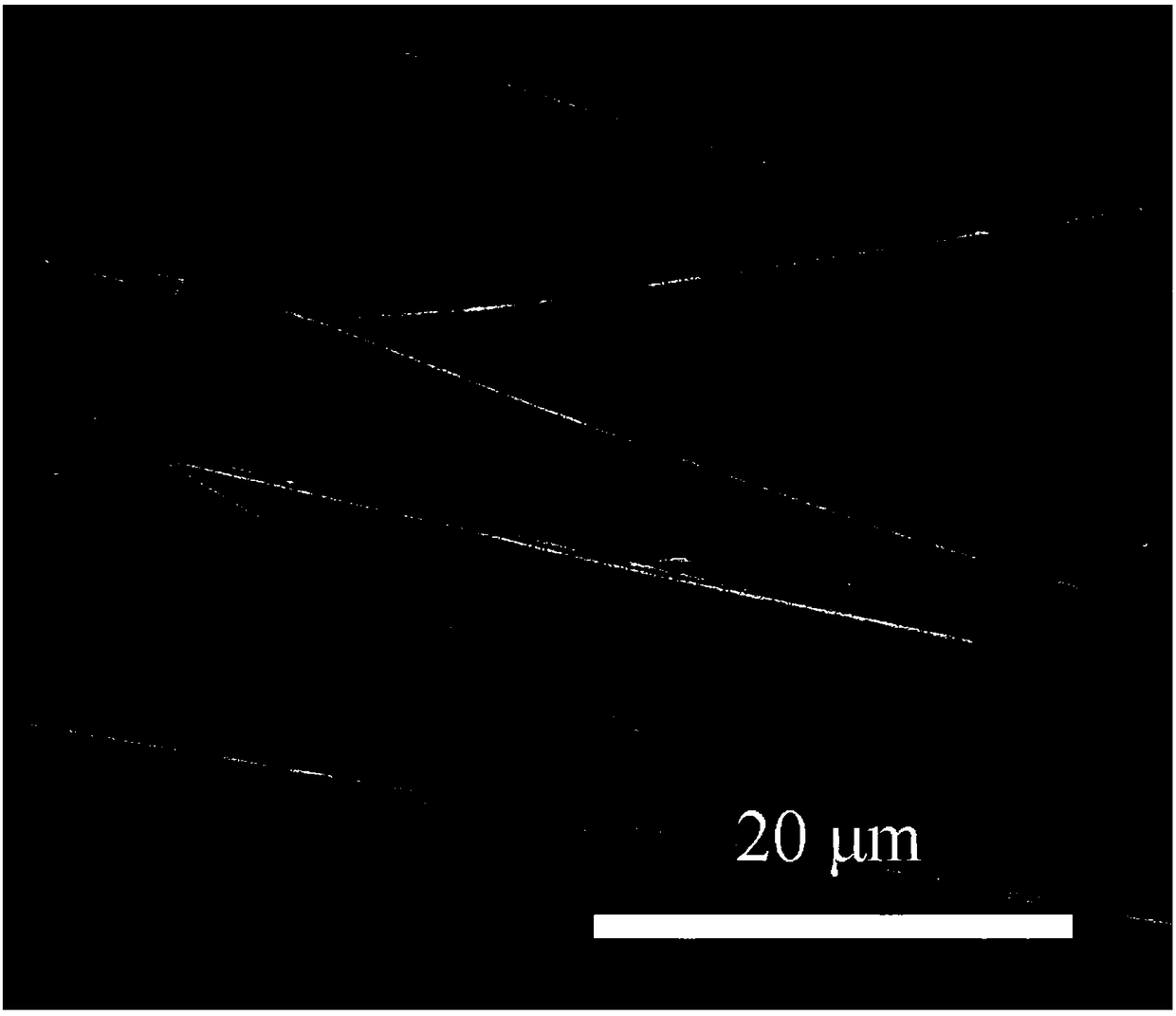

[0036] (1) Dissolve phenolphthalein polyethersulfone with an intrinsic viscosity of 1.0g / dL in DMF, prepare a 15wt% spinning solution, let it stand for defoaming, squeeze the spinning solution out of the spinning pinhole through a metering pump, and The nanofiber film is formed by air stretching and collection. The relevant process parameters are: spinneret diameter 0.8mm, propulsion speed 5ml / h per hole, spinning air pressure 0.08MPa, receiving distance 15cm, spinning time 2h, and the atmosphere used for spinning is nitrogen gas; the obtained nanofiber membrane was dried in vacuum at 80° C. for 10 h to obtain a PES-C nanofiber membrane.

[0037] (2) Prepare a 5wt% solution of PVPK30, add potassium persulfate as an initiator with a mass ratio of 2:1 to PVPK30, raise the temperature at 80°C for 5 hours, and obtain a PVPP solution.

[0038](3) Spray the PVPP solution in step (2) onto the surface of the PES-C nanofiber membrane in step (1) through a solution spraying device, ther...

Embodiment 2

[0044] (1) Dissolve phenolphthalein polyethersulfone with an intrinsic viscosity of 0.65g / dL in DMF, prepare a 25wt% spinning solution, let stand for defoaming, squeeze the spinning solution out of the spinning pinhole through a metering pump, and The nanofiber film is formed by air stretching and collection. The relevant process parameters are: spinneret diameter 0.7mm, propulsion speed 4ml / h per hole, spinning air pressure 0.12MPa, receiving distance 25cm, spinning time 2h, and the atmosphere used for spinning is Nitrogen, and vacuum-dry the obtained nanofiber membrane at 80° C. for 10 h to obtain a PES-C nanofiber membrane.

[0045] (2) Prepare a 3wt% solution of PVPK60, add sodium persulfate as an initiator with a mass ratio of 1:1 to PVPK60, and react at 70°C for 4 hours to obtain a PVPP solution.

[0046] (3) Spray the PVPP solution in step (2) onto the surface of the nanofiber membrane in step (1) through a solution spraying device, thereby obtaining the PES-C / PVPP comp...

Embodiment 3

[0050] (1) Dissolve phenolphthalein polyethersulfone with an intrinsic viscosity of 0.5g / dL in DMF, prepare a 30wt% spinning solution, let it stand for defoaming, squeeze the spinning solution out of the spinning pinhole through a metering pump, and The nanofiber membrane is formed by air stretching and collection. The relevant process parameters are: spinneret diameter 0.5mm, propulsion speed 5ml / h hole, spinning air pressure 0.2MPa, receiving distance 40cm, spinning time 2h, spinning atmosphere The obtained nanofiber membrane was dried under vacuum at 80° C. for 10 h under nitrogen gas to obtain a PES-C nanofiber membrane.

[0051] (2) Prepare a 2wt% solution of PVPK90, add ammonium persulfate as an initiator with a mass ratio of 1:2 to PVPK90, and react at 90°C for 2 hours to obtain a PVPP solution.

[0052] (3) Spray the PVPP solution in step (2) onto the surface of the PES-C nanofiber membrane in step (1) through a solution spraying device, thereby obtaining the PES-C / PVP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com