Preparation method of nanometer titanium dioxide

A nano-titanium dioxide, titanium dioxide technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of poor photocatalytic degradation activity, mixed crystal particle size, complex process, etc., to achieve low cost, prevent The effect of reunion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

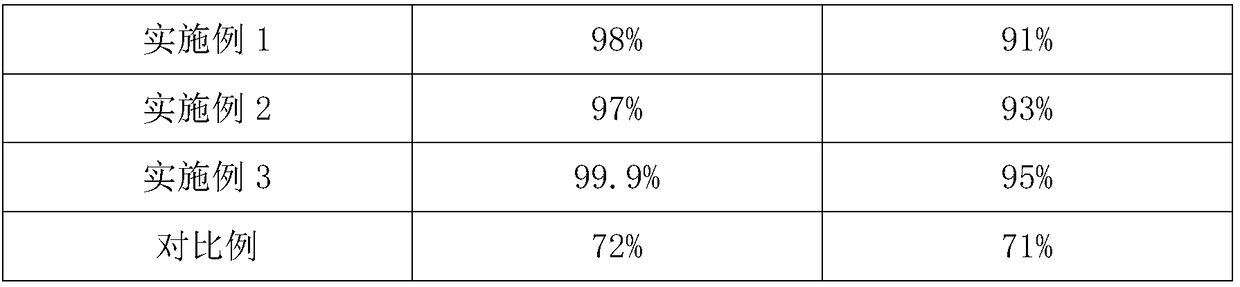

Embodiment 1

[0033] A preparation method of nano-titanium dioxide, comprising the steps of:

[0034] Step 1, adding n-butyl titanate to absolute ethanol, and then adding a dispersant to ultrasonically disperse until completely dissolved to obtain n-butyl titanate dispersion alcohol;

[0035] Step 2, adding the polymer surfactant into distilled water, stirring evenly until completely dissolved, to obtain a dropwise solution;

[0036] Step 3, slowly drop the dropping solution into the n-butyl titanate alcohol solution, seal and stir for 1 hour under slight heat to obtain a suspension;

[0037] Step 4, put the suspension into the reaction kettle for 1 hour of vacuum distillation reaction, after cooling, filter at low temperature to obtain a precipitate of encapsulated titanium dioxide;

[0038] Step 5, adding the encapsulated titanium dioxide precipitate into the ethanol aqueous solution for ultrasonic reaction for 10 minutes, then taking it out and drying it at high temperature to obtain na...

Embodiment 2

[0050] A preparation method of nano-titanium dioxide, comprising the steps of:

[0051] Step 1, adding n-butyl titanate to absolute ethanol, and then adding a dispersant to ultrasonically disperse until completely dissolved to obtain n-butyl titanate dispersion alcohol;

[0052] Step 2, adding the polymer surfactant into distilled water, stirring evenly until completely dissolved, to obtain a dropwise solution;

[0053] Step 3, slowly drop the dropping solution into the n-butyl titanate alcohol solution, seal and stir for 3 hours with slight heat to obtain a suspension;

[0054] Step 4, put the suspension into the reaction kettle for 3h under reduced pressure distillation reaction, after cooling, filter at low temperature to obtain the encapsulated titanium dioxide precipitate;

[0055] Step 5, adding the encapsulated titanium dioxide precipitate into the aqueous ethanol solution for ultrasonic reaction for 20 minutes, then taking it out and drying it at high temperature to obt...

Embodiment 3

[0067] A preparation method of nano-titanium dioxide, comprising the steps of:

[0068] Step 1, adding n-butyl titanate to absolute ethanol, and then adding a dispersant to ultrasonically disperse until completely dissolved to obtain n-butyl titanate dispersion alcohol;

[0069] Step 2, adding the polymer surfactant into distilled water, stirring evenly until completely dissolved, to obtain a dropwise solution;

[0070] Step 3: Slowly add the dropping solution into the n-butyl titanate alcohol solution, seal and stir for 2 hours with slight heat to obtain a suspension;

[0071] Step 4, put the suspension into the reaction kettle for 2 hours of vacuum distillation reaction, after cooling, filter at low temperature to obtain a particle-encapsulated titanium dioxide precipitate;

[0072] Step 5, add the encapsulated titanium dioxide precipitate into the aqueous ethanol solution for ultrasonic reaction for 15 minutes, then take it out and dry it at high temperature to obtain nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com