Modification treatment process for Calotropis gigantea fibers

A treatment process and fiber modification technology, which is applied in the field of Carlo silk fiber modification treatment process, can solve problems such as slippage, flying flowers, and easy brittle fracture of Carlo silk fiber, and achieve a wide range of raw material sources, increase the proportion of fiber mass, The effect of reducing fly problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

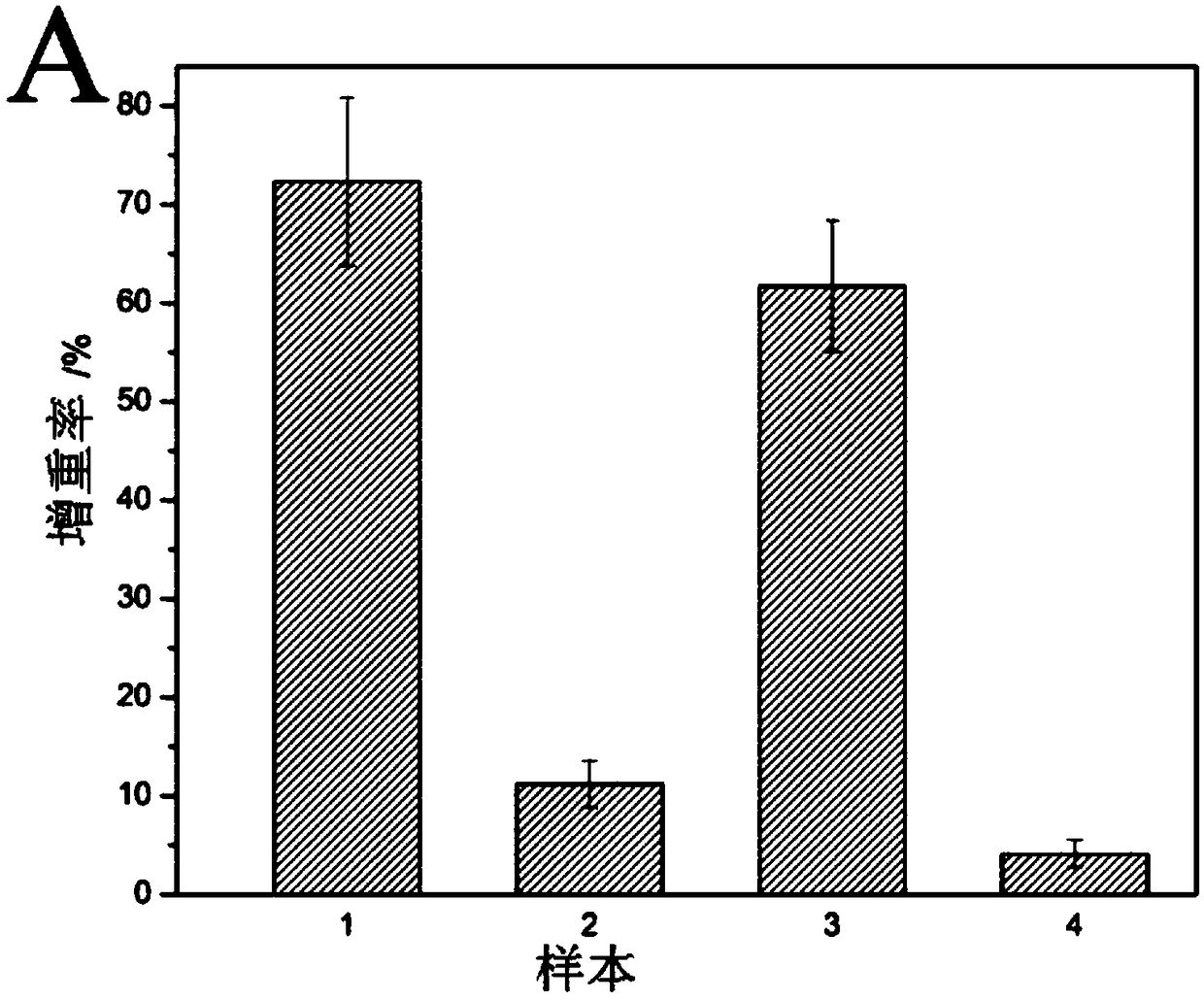

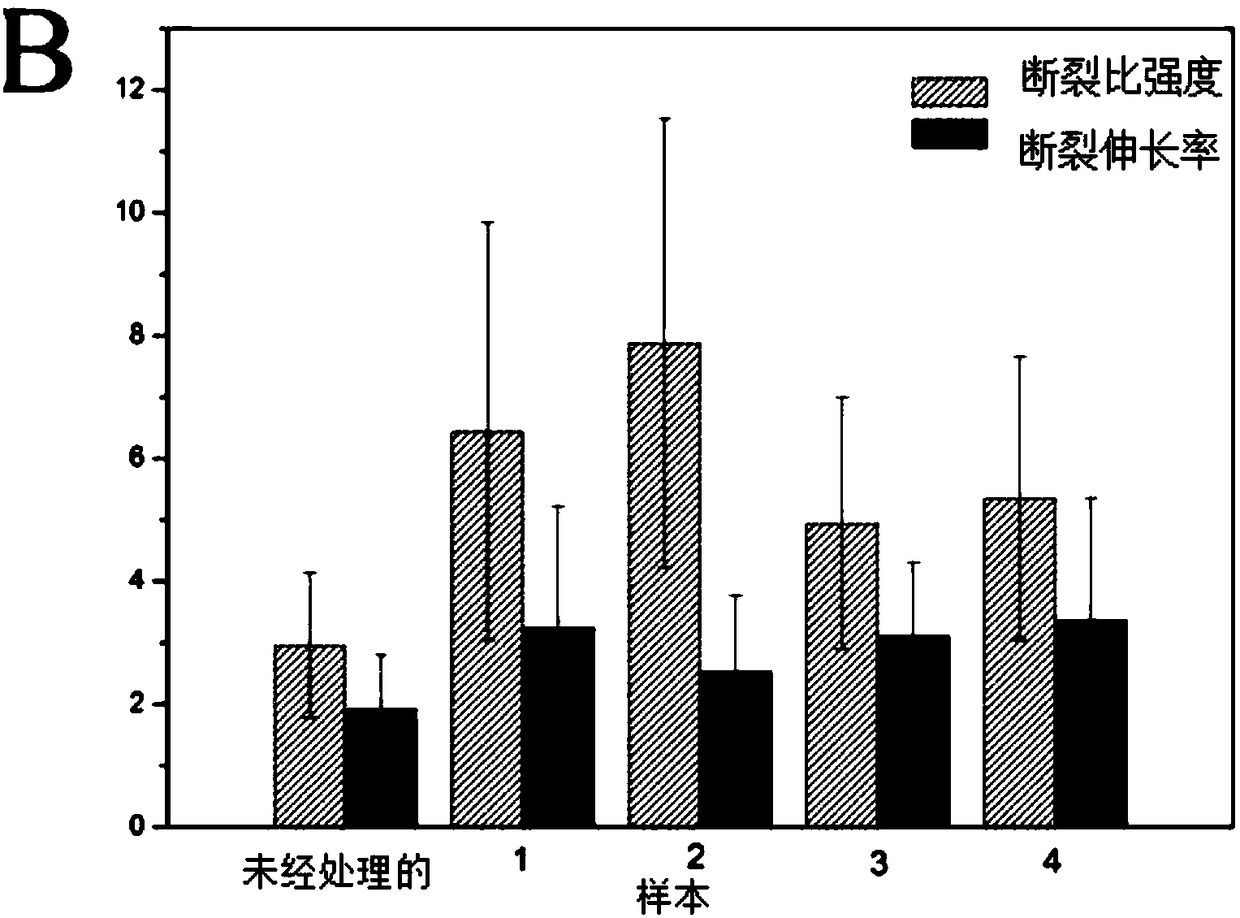

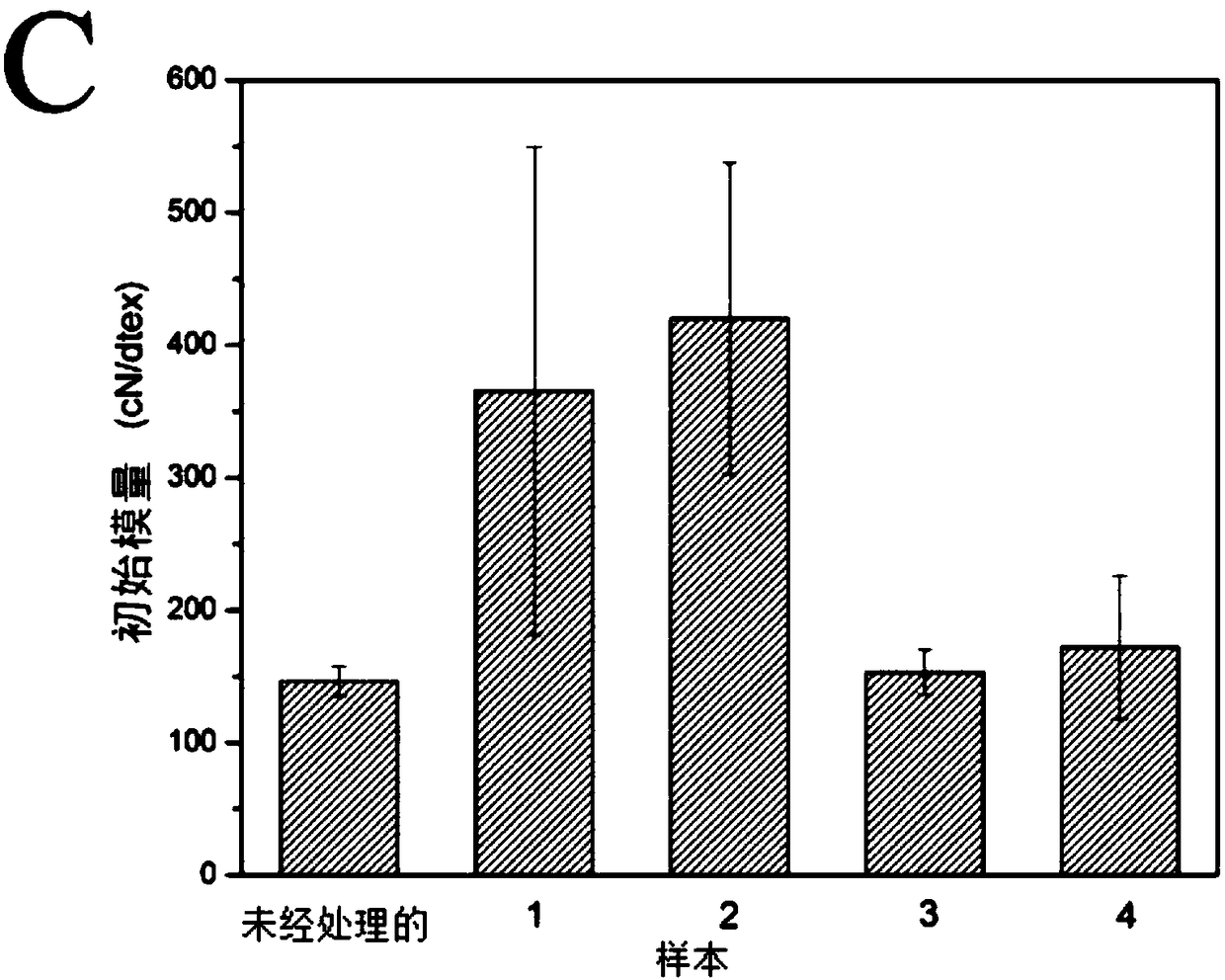

[0030] This implementation case shows a carlos fiber modification process, including:

[0031] Remove the impurities in the Carlo silk fiber, then dry the fiber in an oven to constant weight, put the fiber toughening plasticizer with an effective content of 6~12% into the spraying equipment and spray the dried Carlo silk The fibers are sprayed, and the fiber plasticizing and toughening agent is an auxiliary agent compounded by high molecular polymers, softeners, emulsifiers, organic metal salts, nonionic and anionic surfactants, among which high molecular polymers Polyacrylic acid, derivatives of polyacrylates or sodium alginate, softener is fatty alcohol polyoxyethylene ether, emulsifier is sodium dodecylbenzene sulfonate, organic metal salt is calcium chloride, non-ionic performance The active agent is Pingping plus O, and the anionic surfactant is sodium dodecylsulfonate. Spray 7~13g of cationic softener on 1g of Carlo silk fiber. When spraying, the Carlo silk fiber needs ...

Embodiment 2

[0033] This implementation case shows a carlos fiber modification process, including:

[0034] Remove the impurities in the Carlo silk fiber, then dry the fiber in an oven to constant weight, fill the water-based PU solution with a solid content of 5~25% into the spraying equipment and spray the dried Carlo silk fiber Treatment, the water-based PU solution is an anionic-based water-based polyurethane dispersion, the number-average relative molecular weight is 20,000-50,000, 1g of Carlo silk fiber is sprayed with 7~13g of water-based PU solution, and the Carlo silk fiber needs to be sprayed one by one Spread out to ensure that the fibers are sprayed evenly. The drying temperature is 80~145℃, and the drying time is 1~4h.

Embodiment 3

[0036] This implementation case shows a carlos fiber modification process, including:

[0037]Remove the impurities in the carrousel fiber, then dry the fiber to constant weight in an oven, disperse the carrousel fiber evenly, spray evenly on the carrousel fiber with wool and hair oil, and the wool and wool The oil is made of mineral oil, spindle oil, sage oil, oleic acid, emulsifier, softener, non-ionic and anionic surfactants after emulsification and stirring. The active substance content is 99%, and the pH value is 6-8. Among them, the emulsifier is sorbitan monostearate, polysorbate 60, sodium alkylsulfonate, the softener is castor oil polyoxyethylene ether, the nonionic surfactant is Peregal O (Peregal O), and the anion The surfactant is sodium alkyl sulfonate, add water to the crude oil to make an emulsion and use it, the mass ratio of crude oil and water is 1:3~9, 1g fiber uses 7-13g and crude oil emulsion, after treatment Place the Carlo silk fiber at a temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com