Photovoltaic module and fabrication method thereof

A photovoltaic module and photovoltaic material technology, applied in the field of optical materials, can solve the problems of limited current output capacity, poor ultraviolet stability, and low conversion efficiency, and achieve the effects of increasing current output capacity, weakening aging effect, and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In order to solve the above-mentioned technical problems existing in the prior art, an embodiment of the present invention provides a method for manufacturing a photovoltaic module.

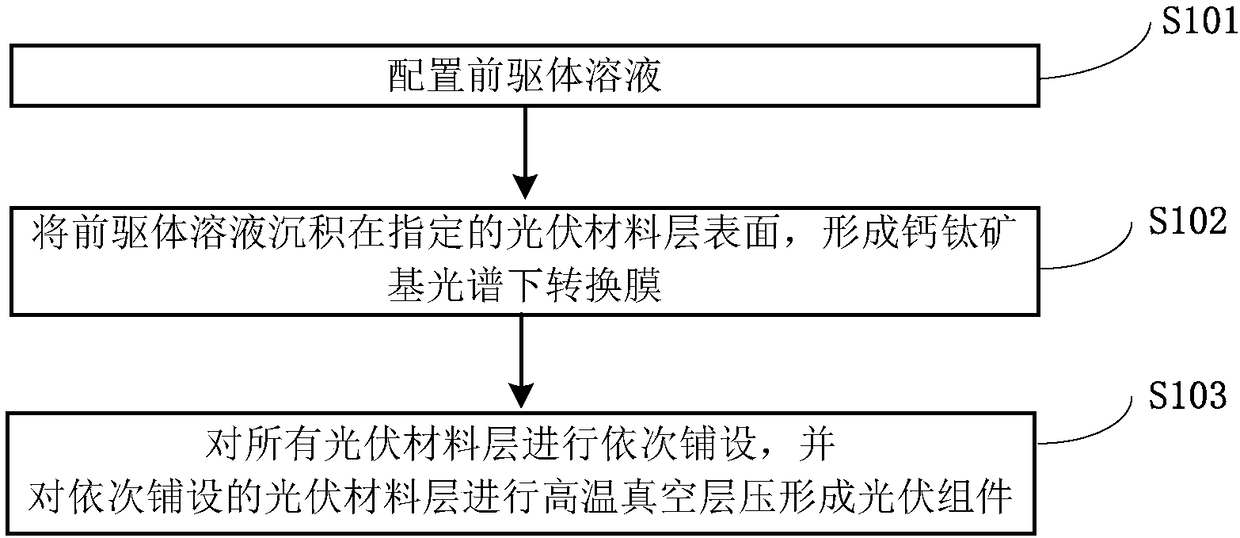

[0049] figure 1 A schematic flow chart of a method for preparing a photovoltaic module according to Embodiment 1 of the present invention is shown.

[0050] refer to figure 1 , the preparation method of the photovoltaic module in this embodiment includes the following steps.

[0051] Step S101, configuring a precursor solution.

[0052] Step S102 , depositing the precursor solution on the surface of the specified photovoltaic material layer to form the perovskite-based spectrum down-conversion film 5 .

[0053]Specifically, the configured precursor solution is evenly coated on the surface of the specified photovoltaic material layer by any one of spin coating method, casting method, blade coating method, dip coating method or spray coating method. Then, dry the precursor solution coate...

Embodiment 2

[0077] In order to solve the above-mentioned technical problems existing in the prior art, an embodiment of the present invention further provides a photovoltaic module.

[0078] Figure 7 A schematic structural diagram of a photovoltaic module according to Embodiment 2 of the present invention is shown.

[0079] refer to Figure 7 The photovoltaic module of this embodiment includes a backplane 1 , a first sealing film 2 , a photovoltaic cell unit 3 , a second sealing film 4 , a perovskite-based spectral down-conversion film 5 and a glass cover 6 arranged in sequence from top to bottom.

[0080] Specifically, the back sheet 1 can be selected from any one of Tedlar back sheet (polyvinyl fluoride PVF), fluorine-containing back sheet, and PET back sheet; the first sealing film 2 and the second sealing film 4 can be selected from ethylene-vinyl acetate copolymer Any one of poly(EVA), ethylene-octene copolymer (POE), polyvinyl butyral (PVB), polyurethane (PU) film; the battery un...

Embodiment 3

[0083] In order to solve the above-mentioned technical problems existing in the prior art, an embodiment of the present invention further provides a photovoltaic module.

[0084] Figure 8 A schematic structural diagram of a photovoltaic module according to Embodiment 3 of the present invention is shown.

[0085] refer to Figure 8 The photovoltaic module of this embodiment includes a backplane 1 , a first sealing film 2 , a photovoltaic cell unit 3 , a perovskite-based spectrum down-conversion film 5 , a second sealing film 4 and a glass cover 6 arranged in sequence from top to bottom.

[0086] The details of the above photovoltaic material layers are the same as those of the photovoltaic material layers in the real-time example 2 photovoltaic module, and will not be repeated here. At the same time, the beneficial effect of applying the photovoltaic module of this embodiment is the same as that of the real-time example 2 photovoltaic module, and will not be repeated here. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com