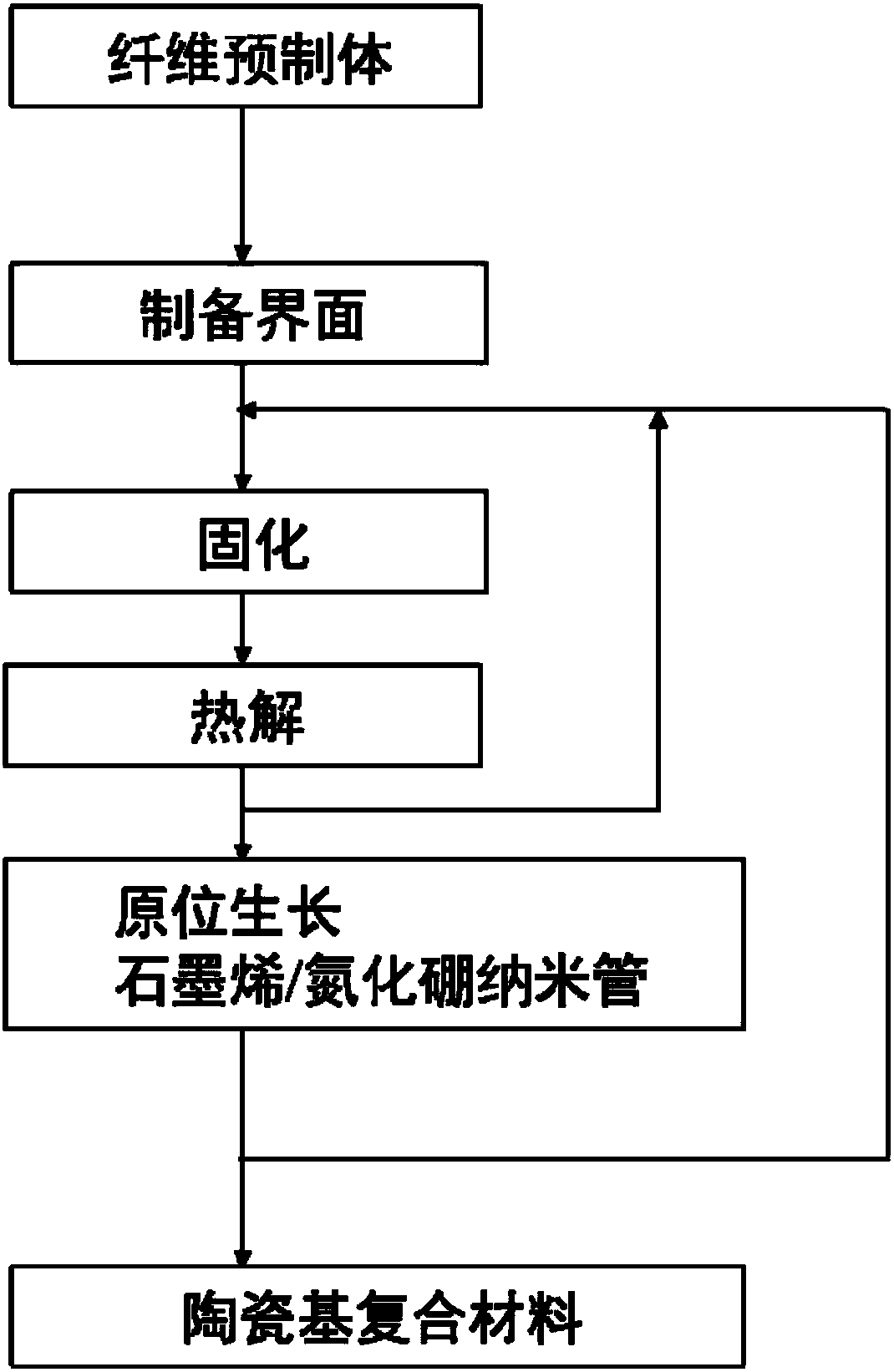

Densification method of PIP (precursor infiltration pyrolysis) in combination with in-situ growth of graphene or boron nitride nanotube ceramic matrix composite

A boron nitride nanotube and composite material technology, which is applied in the field of densification of PIP combined with in-situ growth graphene/boron nitride nanotube ceramic matrix composite materials, can solve problems such as affecting the performance of materials, and achieves a simple preparation method and improved High performance and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027]The preparation method of the slurry includes the steps of: adding graphene into the ethanol aqueous solution, stirring evenly, and ultrasonically dispersing for 0.5-5 hours to prepare a graphene dispersion with a concentration of 0.5-5 g / L; mixing the graphene dispersion and boron Powder mixing, first use zirconia ball milling for 50-130 hours, and then use steel ball milling for 3-24 hours to obtain slurry; wherein, the ratio of ball to material is (1-150): 1, and the rotating speed is 200-450rpm; The volume fraction of ethanol is 20%-50%, and the mass ratio of graphene dispersion liquid and boron powder is (5-50):1.

[0028] S4 (Cyclic Densification): Repeat the steps of S2 and / or S3 for the initial product of the ceramic matrix composite material to obtain an in-situ growth graphene / boron nitride nanotube dense fiber reinforced ceramic matrix composite material.

Embodiment 1

[0031] This embodiment provides a method for densifying a PIP combined in-situ growth graphene / boron nitride nanotube ceramic matrix composite material, comprising the steps of:

[0032] S1 (preparing interface layer): depositing a silicon carbide interface layer on the surface of the silicon carbide carbon fiber preform fabric to obtain a preform prepared with an interface layer;

[0033] Among them, the silicon carbide interface layer was prepared by chemical vapor deposition (CVD), with MTS as the precursor, hydrogen with a flow rate of 200sccm as the carrier gas and diluent gas, and argon with a flow rate of 75sccm as the protective gas.

[0034] S2 (immersion cracking): put the preform prepared with the interface layer into the precursor solution and immerse it for 24 hours. After the immersion is completed, take the immersed preform out of the immersion equipment, put it in the air, and let it dry naturally at room temperature. Dry, then put it into an oven to dry at 120...

Embodiment 2

[0041] This embodiment provides a method for densifying a PIP combined in-situ growth graphene / boron nitride nanotube ceramic matrix composite material, comprising the steps of:

[0042] S1 (preparing the interface layer): depositing a pyrolytic carbon layer on the surface of the silicon carbide SiC fiber preform fabric to obtain a preform prepared with an interface layer;

[0043] Among them, when chemical vapor deposition (CVD) is used to prepare the pyrolytic carbon layer, methane is used as the gas source, and N 2 For the carrier gas, the temperature is 900 ℃, the pressure is 3kPa.

[0044] S2 (immersion cracking): put the preform prepared with the interface layer into the precursor solution and immerse it for 24 hours. After the immersion is completed, take the immersed preform out of the immersion equipment, put it in the air, and let it dry naturally at room temperature. Dry, then put it into an oven to dry at 120°C for 5 hours; take it out after drying, heat up to 300...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com