Preparation method of zinc sulfide and graphene oxide compound and application of compound to lithium-sulfur battery positive electrode material

A graphene and composite technology, applied in the field of new energy materials, can solve the problems of ineffective fixation, poor coulombic efficiency, electrode pulverization, etc., and achieve the effect of accelerating transfer and transmission, accelerating kinetic reaction, and mild preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

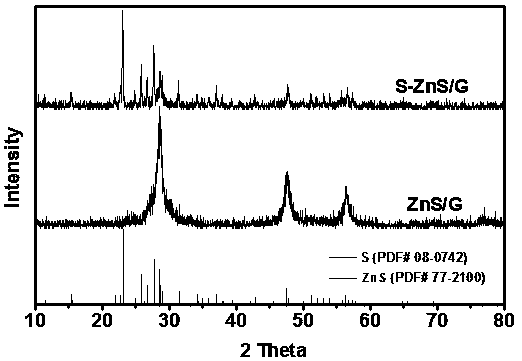

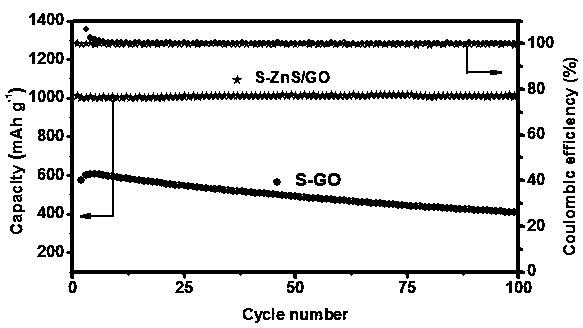

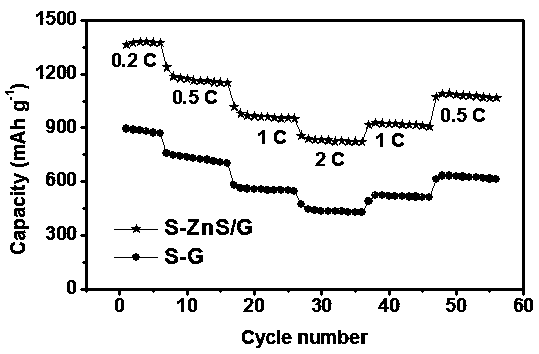

[0036] A preparation method of a composite (ZnS / GO) material of zinc sulfide and graphene oxide:

[0037] Synthesis method of ZnS / GO: 0.408 ml of carbon disulfide (CS 2 ) solution and 70 ml of ethylenediamine solution (0.075 M) were stirred and mixed until CS 2 The droplets were completely dissolved; after that, 60 mg of GO was added to 80 mL of ethylene glycol and sonicated for 120 min; then, this solution was added to the above solution and continued to stir for 60 min. Finally, 35 mL of zinc nitrate (Zn(NO 3 ) 2 ) solution (0.05 M) was added dropwise to the mixture under continuous stirring, transferred to the kettle, 180 o C was heated for 12 h, cooled to room temperature, and the samples were centrifuged and washed with deionized water and ethanol. placed at 60 o Dry in an oven at C for 12 h;

[0038] Preparation of S-ZnS / GO: Prepare 60 mL of 1 mg / mL ZnS / GO solution, and then mix with 0.24 g of Na 2 SO 3 , 1.22 g of Na 2 S·9H 2 O was stirred and mixed for 30 mi...

Embodiment 2

[0045] Synthesis method of ZnS / GO: 0.408 mL of carbon disulfide (CS 2 ) solution and 75 mL of ethylenediamine solution (0.075 M) were stirred and mixed until CS 2 The droplets evaporate completely. Afterwards, 60 mg of GO was added to 80 mL of ethylene glycol for sonication; then, this solution was added to the above solution, and the stirring was continued for 120 min. Finally, 37.5 mL of zinc nitrate (Zn(NO3) 2 ) solution (0.05M) was added dropwise to the mixture under continuous stirring, and transferred to the kettle, 180 o C was heated for 12 h, cooled to room temperature, and the samples were centrifuged and washed with deionized water and ethanol. placed at 80 o C oven-dried for 12 h.

[0046] Preparation of S-ZnS / GO: Prepare 60 mL of 1 mg / mL ZnS / GO solution. Then with 0.24 g of Na 2 SO 3 , 1.22 g of Na 2 S·9H 2 O was stirred and mixed for 30 min, after which 8 mL of 1 mol / L H 2 SO 4 Continue to stir for 12h, the product is separated by centrifugation, and ...

Embodiment 3

[0053] Synthesis method of ZnS / GO: 0.408 mL of carbon disulfide (CS 2 ) solution and 70 mL of ethylenediamine solution (0.075 M) were stirred and mixed until CS 2 The droplets evaporate completely. Afterwards, 60 mg of GO was added to 80 mL of ethanol for sonication. Then, this solution was added to the above solution, and the stirring was continued for 30 min. Finally, 30 ml of zinc nitrate (Zn(NO 3 ) 2 ) solution (0.05 M) was added dropwise to the mixture under continuous stirring, transferred to a 100 mL kettle, 180 o C was heated for 12 h, cooled to room temperature, and the samples were centrifuged and washed with deionized water and ethanol. placed at 70 o C oven-dried for 12 h.

[0054] Preparation of S-ZnS / GO: Prepare 60 mL of 1 mg / mL ZnS / GO solution. Then with 0.24 g of Na 2 SO 3 , 1.22 g of Na 2 S·9H 2 O was stirred and mixed for 30 min, after which 8 mL of 1 mol / L H 2 SO 4 Continue to stir for 12h, the product is separated by centrifugation, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com