Preparation and application of a highly biocompatible biodegradable bone filling material

A technology of filling materials and compounds, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problems of not improving the degradation performance of PPDO in vitro

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

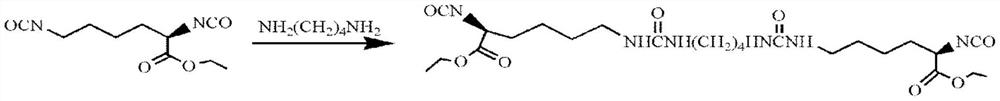

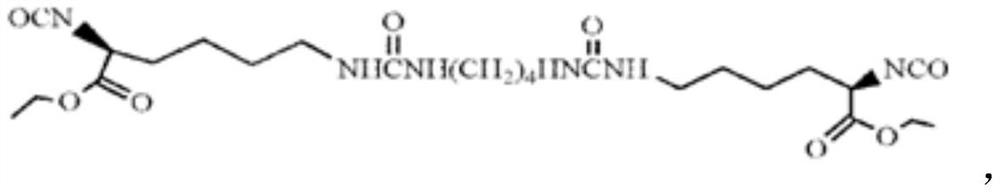

[0075] Preparation of Diisocyanate Chain Extender LBL Containing Urea Structure

[0076] Under dry nitrogen protection and mechanical stirring, add 1,4-butanediamine dropwise to L-lysine diisocyanate (-NCO:-NH 2 =8:1, molar ratio), after reacting at room temperature for 2h, add four times the volume of n-hexane to the reaction product, after stirring evenly, obtain a white solid by suction filtration, wash with n-hexane repeatedly until the filtrate IR detects that there is no -NCO absorption Peak (2270cm -1 ), vacuum-dried to constant weight to obtain white powder LBL.

Embodiment 2

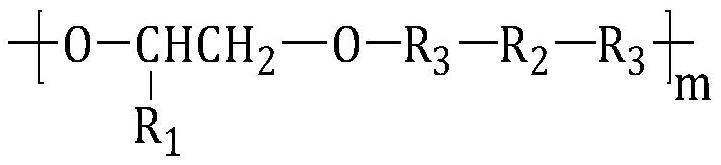

[0078] Under the protection of dry nitrogen, 6.5g (5mmol) terminal dihydroxypolyethylene glycol phosphorylcholine compound (PC-(OH) 2 ,M n =1300) and 60.0g (25mmol) polydioxanone (PPDO, M n =2400) were mixed, N,N-dimethylformamide (DMF) was added to dissolve (0.5g / mL), the temperature of the reaction system was raised to 80°C, and a DMF solution (1.0g / mL) of LBL (30.6mmol) was added dropwise, After the dropwise addition, keep the temperature and continue the reaction for 4.0 hours, lower to room temperature, then add DMF to make a solution with a concentration of about 10%, settle with 8 times the volume of glacial ether, and dry the obtained solid under vacuum at 35°C to obtain high biocompatibility and biodegradability Polyurethane urea;

[0079] Dissolve the polyurethane urea in dioxane, control the mass volume concentration to 60%, stir the solution at 40° C. for 12 hours to obtain a homogeneous solution, put it into a mold (polytetrafluoroethylene) and freeze-dry to obt...

Embodiment 3

[0081] Under the protection of dry nitrogen, 6.5g (5mmol) terminal dihydroxypolyethylene glycol phosphorylcholine compound (PC-(OH) 2 ,M n =1300) and 48.0g (20mmol) polydioxanone (PPDO, M n =2400) were mixed, N,N-dimethylformamide (DMF) was added to dissolve (0.5g / mL), the temperature of the reaction system was raised to 85°C, a DMF solution (1.0g / mL) of LBL (25.8mmol) was added dropwise, After the dropwise addition, keep the temperature and continue the reaction for 3.5 hours, lower to room temperature, then add DMF to make a solution with a concentration of about 10%, settle with 8 times the volume of glacial ether, and dry the obtained solid under vacuum at 35°C to obtain high biocompatibility and biodegradability Polyurethane urea;

[0082] Dissolve the polyurethane urea in dioxane, control the mass volume concentration to 60%, stir the solution at 40° C. for 12 hours to obtain a homogeneous solution, put it into a mold (polytetrafluoroethylene) and freeze-dry to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com