Ternary lithium ion battery positive electrode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of increasing the difficulty and cost of material storage, decreasing cycle performance and safety performance, and low efficiency of initial charge and discharge, and achieving shortened The effect of charging and discharging time, improving electrochemical performance and reducing charge transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of ternary lithium ion battery cathode material that one embodiment of the present invention proposes, it comprises:

[0028] Graphene is mixed with an organic solvent to obtain a graphene slurry;

[0029] Mixing and ball milling the graphene slurry with metal compounds and organic solvents, adding ternary materials, and continuing ball milling to obtain a mixed slurry;

[0030] Suction filter or rotary evaporate the mixed slurry, and dry at 100-130°C for 12-36 hours to obtain a mixed powder;

[0031] The mixed powder is calcined in an inert gas atmosphere to obtain a positive electrode material for a ternary lithium ion battery.

[0032] Preferably, the organic solvent is at least one of N-methylpyrrolidone, ethanol, acetone and tetrahydrofuran.

[0033] Preferably, the metal compound is aluminum hydroxide and / or magnesium hydroxide.

[0034] Preferably, the rotating speed of the ball mill is 250r / min, the ball milling time is 20-240min,...

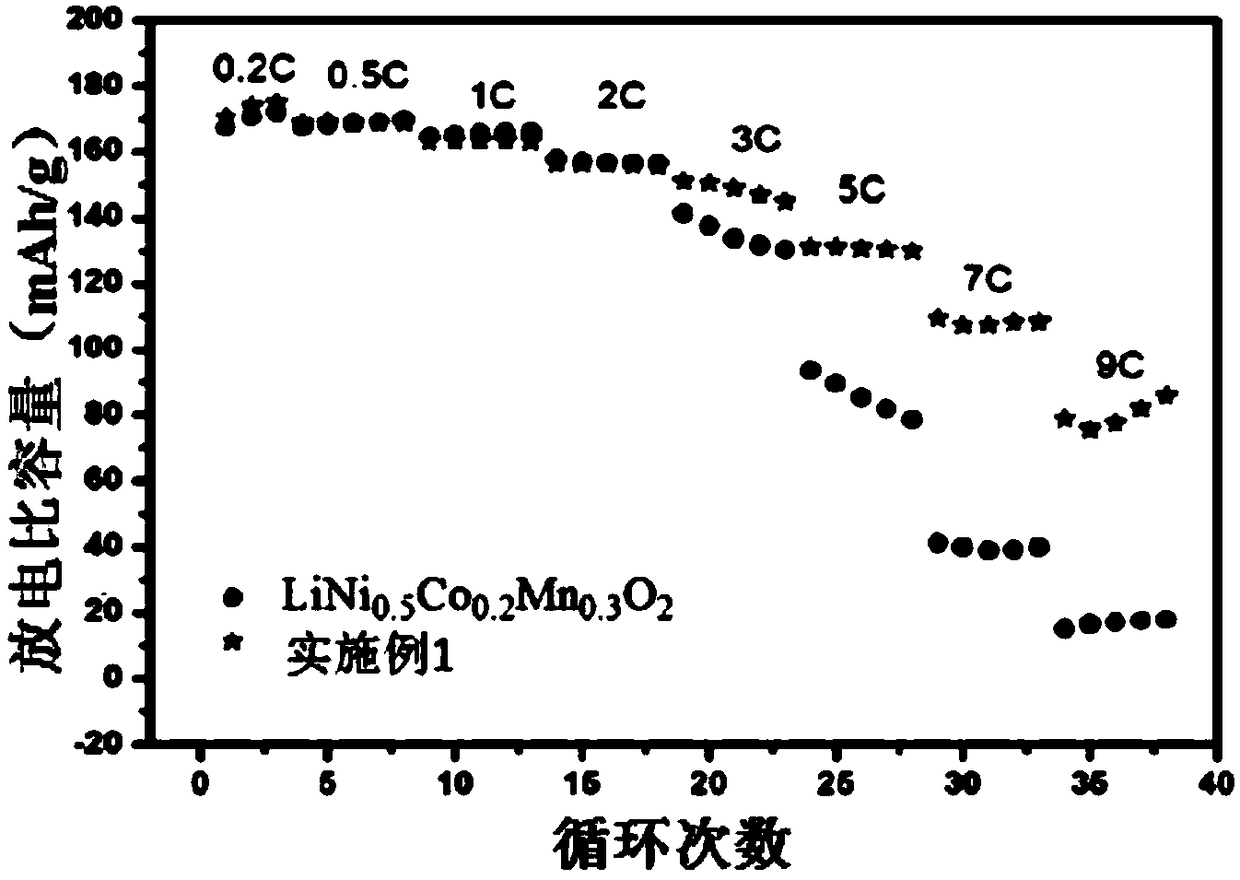

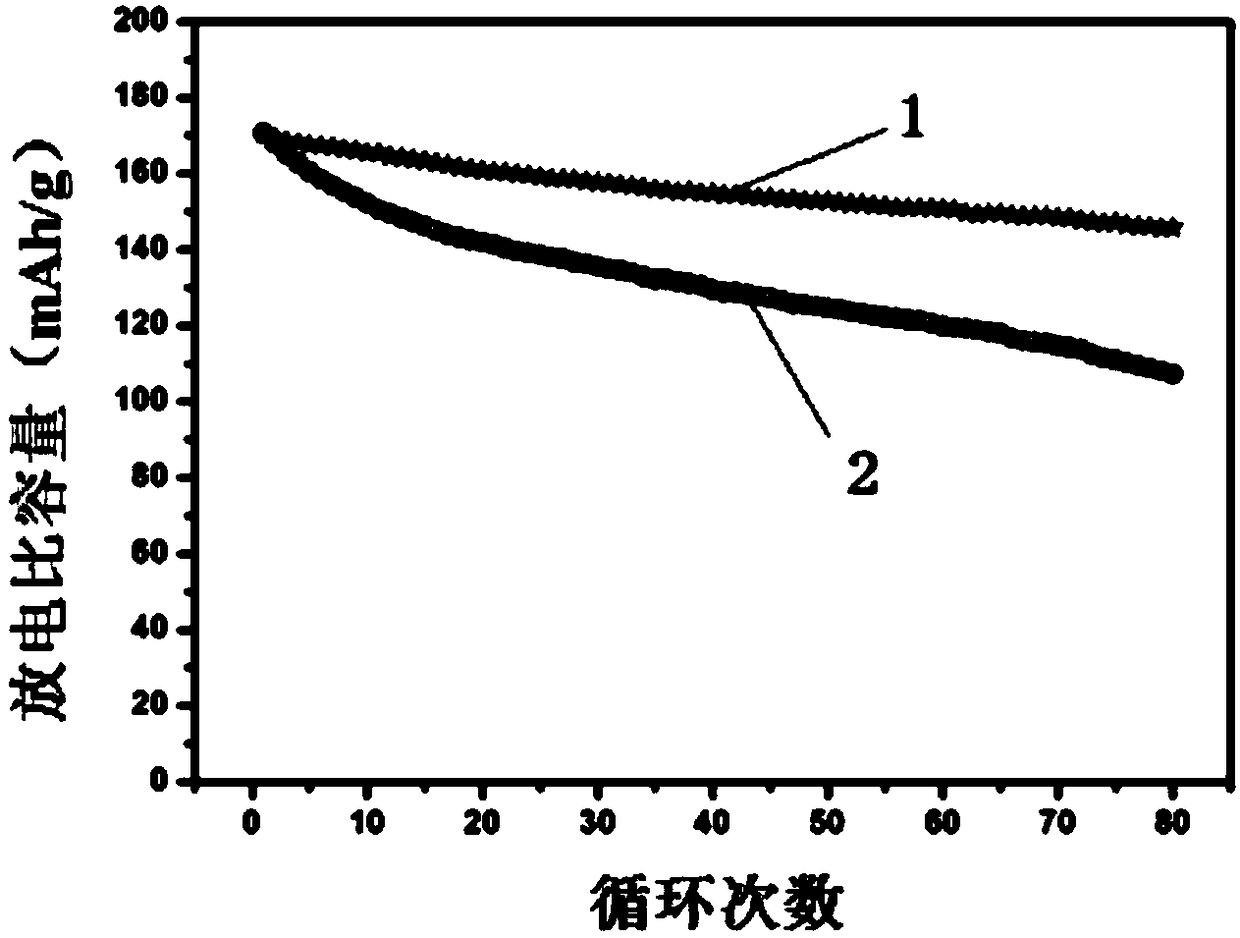

Embodiment 1

[0041] A kind of preparation method of ternary lithium ion battery cathode material that one embodiment of the present invention proposes, it comprises:

[0042] Graphene is mixed with N-methylpyrrolidone to obtain graphene slurry;

[0043] 0.061g Al(OH) 3 Add to 30.26g, 2wt% graphene slurry, and add 50g N-methylpyrrolidone at the same time to reduce the viscosity; after mixing, ball mill in a ball mill for 50min at a speed of 300r / min, changing the direction of rotation every 5min ; join LiNi 0.5 co 0.2 mn 0.3 o 2Powder 50g, then continue ball milling for 90min, the rotating speed is 300r / min, to obtain mixed slurry;

[0044] The mixed slurry was subjected to a rotary evaporation operation in a rotary evaporator to evaporate the solvent N-methylpyrrolidone, and then placed in a vacuum drying oven for vacuum drying for 24 hours at a drying temperature of 120°C to obtain a mixed powder;

[0045] The mixed powder was calcined at 850 °C for 6 h in an inert gas atmosphere in...

Embodiment 2

[0050] A kind of preparation method of ternary lithium ion battery cathode material that one embodiment of the present invention proposes, it comprises:

[0051] Graphene is mixed with N-methylpyrrolidone to obtain graphene slurry;

[0052] 0.015g Mg(OH) 2 Add to 26.85g, 3wt% graphene slurry, and add 46.78g N-methylpyrrolidone at the same time to reduce the viscosity; after mixing, ball mill in a ball mill for 50min at a speed of 300r / min, changing the rotation every 5min Orientation; add LiNi 0.6 co 0.2 mn 0.2 o 2 Powder 50g, then continue ball milling for 90min, the rotating speed is 300r / min, to obtain mixed slurry;

[0053] The mixed slurry was subjected to a rotary evaporation operation in a rotary evaporator to evaporate the solvent N-methylpyrrolidone, and then placed in a vacuum drying oven for vacuum drying for 24 hours at a drying temperature of 120°C to obtain a mixed powder;

[0054] The mixed powder was calcined at 700 °C for 5 h in an inert gas atmosphere i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com