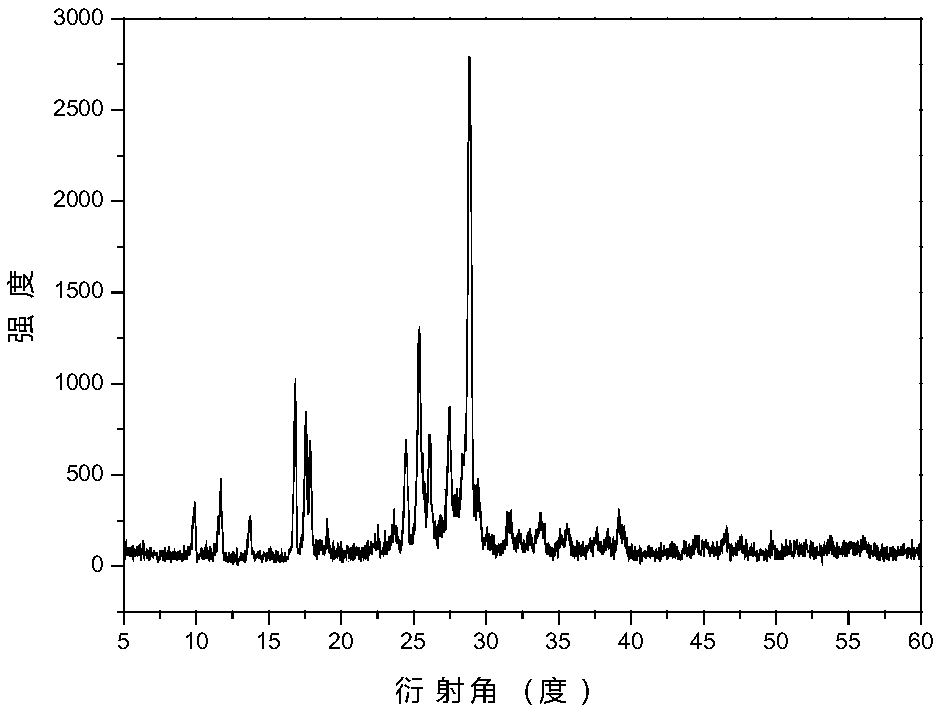

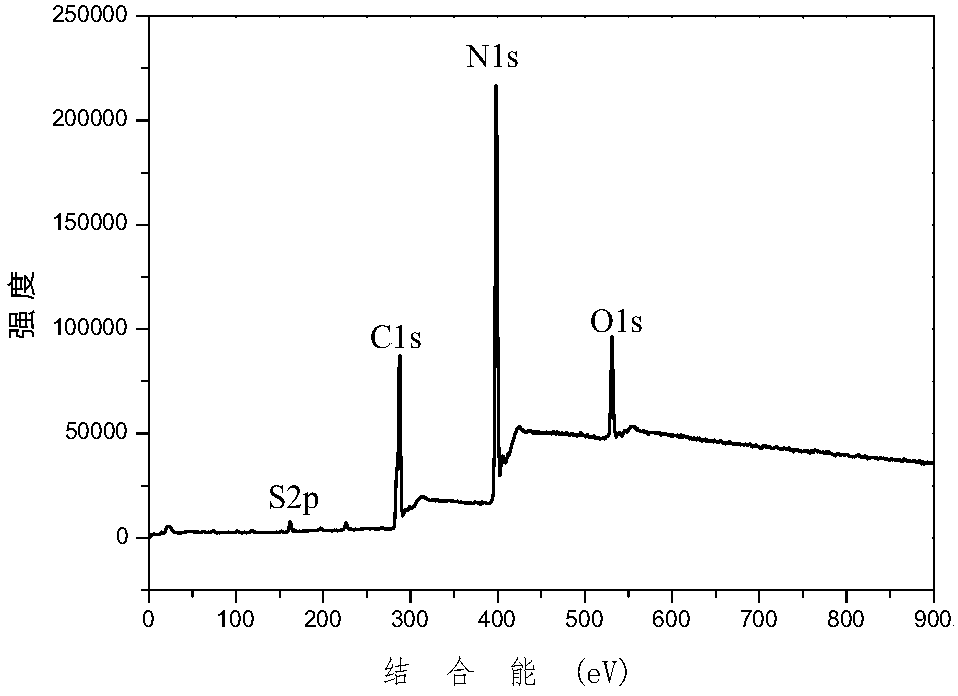

Nitrogen sulfur doped carbon nanosphere synthesized by solid-phase microwave method, preparation method and application thereof

A technology of carbon nanospheres and nitrogen doping, which is applied in the direction of nanotechnology, nanocarbon, and nanotechnology for materials and surface science, and can solve the problems of complicated experimental operation steps, expensive instruments and equipment, high energy consumption, etc., and achieve Good cycle stability, high specific capacity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The method for preparing nitrogen-sulfur-doped carbon nanospheres synthesized by solid-phase microwave method comprises the following steps:

[0033] (1) Mix carbon source, nitrogen source, sulfur source, and sodium α-alkenyl sulfonate in a molar ratio, and grind on an agate mortar for 10-20 minutes to obtain a mixture;

[0034] (2) Grinding graphene on an agate mortar for 10-20min to obtain powder, the obtained powder has a magnetic field strength of 6300-6800GS, an ultrasonic power of 500-600W, a temperature of 50-55°C, and a rotation speed of 200-300r / min, stirring for 30-40min to obtain graphene energy powder;

[0035] (3) Mix the mixture prepared in step (1), the graphene energy powder prepared in step (2), alkane coupling agent KH-57, and ethylene-acrylic acid copolymer in molar ratios, and grind them for 15 minutes in an agate mortar. -25min, to prepare the mixed powder, put the obtained mixed powder into a special glass beaker for microwave oven, then put the ...

Embodiment 1

[0040] A solid-phase microwave synthesis of carbon nanospheres doped with nitrogen and sulfur, in molar parts, including the following raw materials: 1 part of carbon source, 2.5 parts of nitrogen source, 2.3 parts of sulfur source, 0.09 part of graphene energy powder, silane di 0.03 parts of joint agent KH-57, 0.04 parts of sodium α-olefin sulfonate, and 0.2 parts of ethylene-acrylic acid copolymer.

[0041] The carbon source is glucose.

[0042] The nitrogen source is urea.

[0043] The sulfur source is thiourea.

[0044] The method for preparing nitrogen-sulfur-doped carbon nanospheres synthesized by solid-phase microwave method comprises the following steps:

[0045] (1) Mix carbon source, nitrogen source, sulfur source, and sodium α-alkenyl sulfonate in a molar ratio, and grind for 10 minutes on an agate mortar to obtain a mixture;

[0046] (2) Grinding graphene on the agate mortar for 10min to obtain powder, the obtained powder is 6500GS in magnetic field strength, 560W...

Embodiment 2

[0050] A solid-phase microwave synthesis of carbon nanospheres doped with nitrogen and sulfur, in molar parts, including the following raw materials: 1 part of carbon source, 3 parts of nitrogen source, 1.2 parts of sulfur source, 0.06 part of graphene energy powder, silane di 0.02 parts of joint agent KH-57, 0.05 parts of sodium α-olefin sulfonate, and 0.1 parts of ethylene-acrylic acid copolymer.

[0051] The carbon source is glucose.

[0052] The nitrogen source is urea.

[0053] The sulfur source is thiourea.

[0054] The method for preparing nitrogen-sulfur-doped carbon nanospheres synthesized by solid-phase microwave method comprises the following steps:

[0055] (1) Mix the carbon source, nitrogen source, sulfur source, and sodium α-alkenyl sulfonate in a molar ratio, and grind for 20 minutes on an agate mortar to obtain a mixture;

[0056] (2) Grinding on the agate mortar for 12min to make powder, the obtained powder is 6300GS in magnetic field strength, 500W in ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com