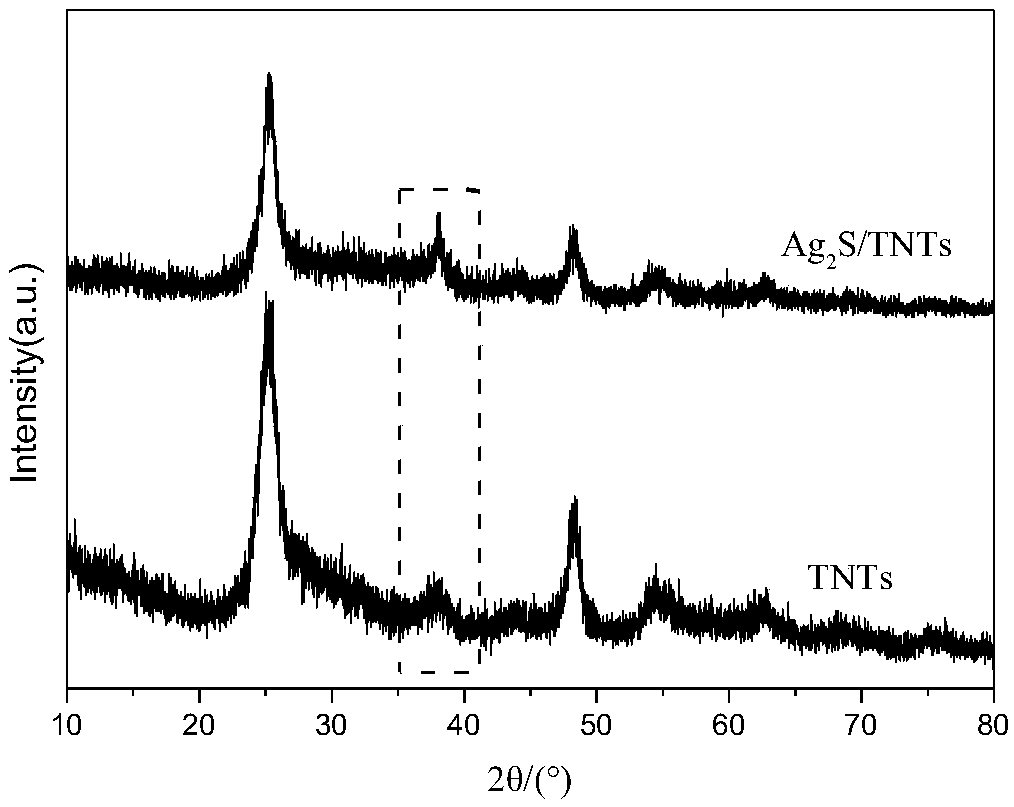

Method for preparing TiO2 nanotubes (TNTs) based composite through biological method

A technology for titanium dioxide and composite materials, which is applied in the field of biological preparation of titanium dioxide tube-based composite materials, can solve the problems of harsh conditions, secondary environmental pollution, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

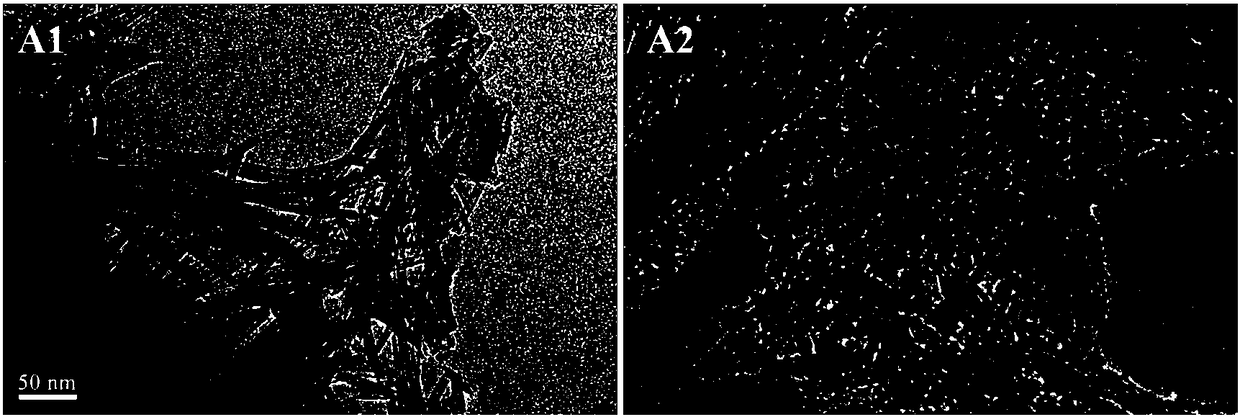

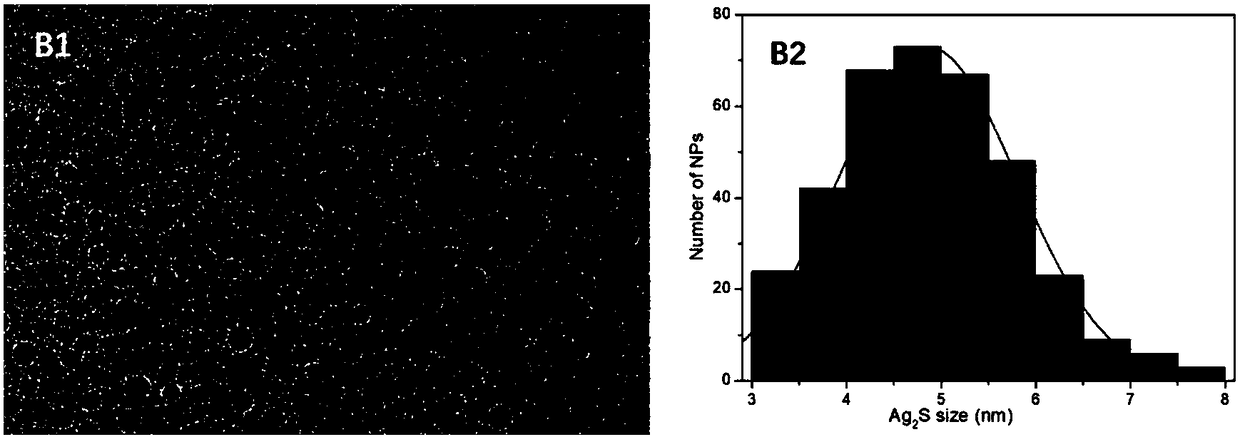

[0034] A method for biologically preparing titanium dioxide tube-based composite materials, comprising the steps of:

[0035] S1. Prepare LB medium: take tryptone 10g / L, yeast powder 5g / L, and NaCl 10g / L as the standard, weigh a certain amount of tryptone, yeast powder, and NaCl, add them to deionized water, mix well, and pack Seal it, sterilize it under high temperature and high pressure, and store it after cooling down for later use.

[0036] S2. Preparation of anaerobic medium: Weigh 4.766g of N-(2-hydroxyethyl)piperazine-N'-2-ethanesulfonic acid, 2.242g of sodium lactate, 0.46g of sodium chloride, 0.255g of ammonium sulfate, seven Magnesium sulfate hydrate 0.024g, trace element stock solution 5mL, ultrapure water 950mL, mix well, adjust pH to 7.0 with 0.1mol / L NaOH solution, set volume to 1L and divide into serum bottles, fill with nitrogen for 5min to exhaust The dissolved oxygen in the bottle is sealed with a butyl rubber stopper, capped, sterilized at high temperature ...

Embodiment 2

[0043] A kind of preparation method that biological method prepares titanium dioxide tube-based composite material, its steps are identical with embodiment 1, difference is:

[0044] In step S1, the amounts of each raw material prepared were tryptone 8g / L, yeast powder 7g / L, and NaCl 8g / L.

[0045] In the S2 step, with the final constant volume of 1L as the standard, the dosages of the prepared raw materials are respectively: 4.5g of N-(2-hydroxyethyl)piperazine-N'-2-ethanesulfonic acid, 2.5g of sodium lactate, and Sodium chloride 0.4g, ammonium sulfate 0.3g, magnesium sulfate heptahydrate 0.04g, trace element stock solution 2mL, ultrapure water 950mL; wherein the concentration of NaOH solution used for pH adjustment is 0.05mol / L; , the amount of each raw material added is: nitrilotriacetic acid 1.0g, magnesium sulfate 2.0g, calcium chloride dihydrate 0.5g, sodium chloride 1.5g, manganese sulfate 0.3g, zinc sulfate heptahydrate 0.01g, heptahydrate Ferrous sulfate 0.15g, cobal...

Embodiment 3

[0051] A method for biologically preparing titanium dioxide tube-based composite material, the steps of which are the same as in Example 1, except that:

[0052] In the S1 step, the amounts of each raw material prepared were respectively 12 g / L of tryptone, 3 g / L of yeast powder, and 12 g / L of NaCl.

[0053] In the S2 step, with the final constant volume of 1 L as the standard, the dosages of each raw material prepared are: 5.0 g of N-(2-hydroxyethyl)piperazine-N'-2-ethanesulfonic acid, 2.0 g of sodium lactate, and Sodium chloride 0.5g, ammonium sulfate 0.2g, magnesium sulfate heptahydrate 0.01g, trace element stock solution 7mL, ultrapure water 950mL; wherein the concentration of NaOH solution used for pH adjustment is 0.2mol / L; when preparing the trace element stock solution , the amount of each raw material added is: nitrilotriacetic acid 2.0g, magnesium sulfate 3.0g, calcium chloride dihydrate 1.5g, sodium chloride 0.5g, manganese sulfate 0.7g, zinc sulfate heptahydrate 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com