Preparation method and application of hollow carbon sphere micro-nano agglomerate/sulfur composite material

A hollow carbon sphere and composite material technology, which is applied to sulfur compounds, chemical instruments and methods, carbon fluoride, etc., can solve the problem of low tap density of nano hollow carbon spheres, reduced active substance content, and easy cracking and powder removal of pole pieces. problem, to achieve the effects of good cycle performance, improved tap density, and simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

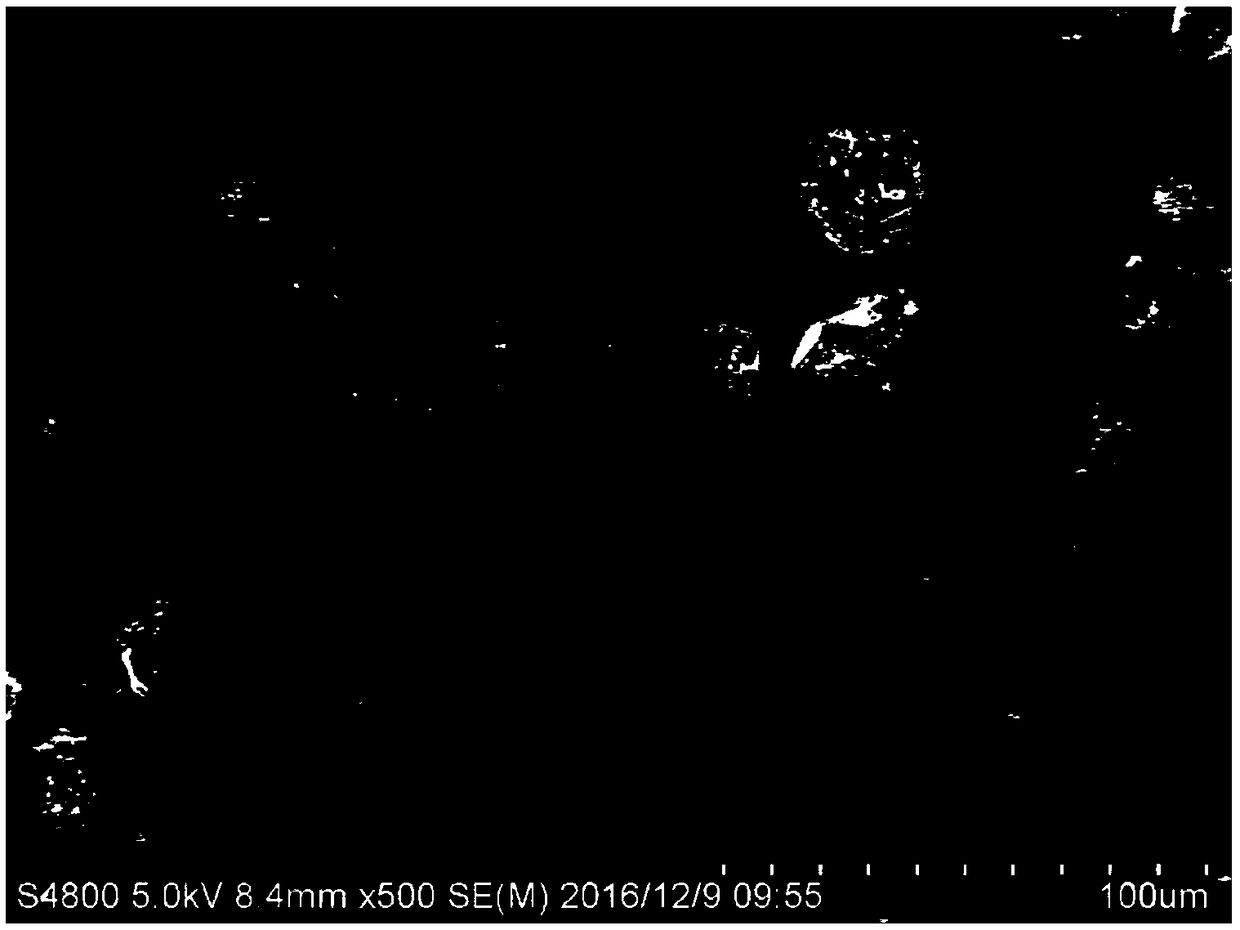

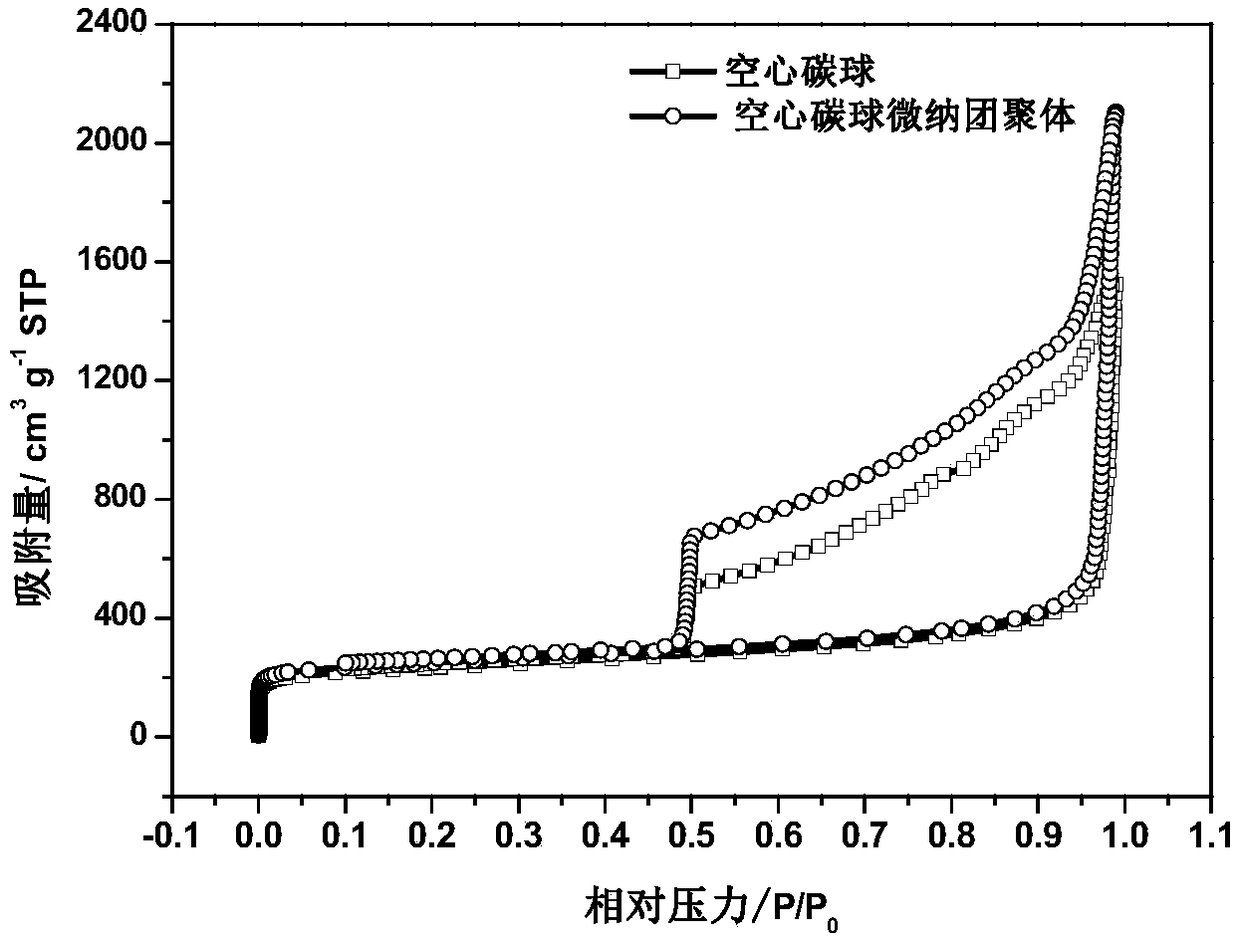

[0035]A method for preparing hollow carbon sphere micro-nano aggregates, comprising the following steps:

[0036] (1) Add 15ml of tetraethyl orthosilicate to a mixed solvent consisting of 10ml of ammonia water, 200ml of ethanol, and 100ml of water under magnetic stirring, stir at 30°C for 2h, then add 10g of glucose, stir for 2h, place in water React in a hot kettle at 190°C for 12 hours, and centrifugally filter the product to obtain caramelized glucose-coated silicon dioxide nanosphere powder.

[0037] (2) Disperse 2.0 g of caramelized glucose-coated silica nanosphere powder in 20 ml of water, ultrasonicate for 3 h, and then dissolve 10 g of LA133 (multi-component polyacrylonitrile copolymer water-based adhesive) aqueous solution with a solid content of 10% Add dropwise to the above dispersion liquid and stir evenly, and stir at 80°C until evaporated to dryness to obtain a hollow carbon sphere micro-nano structure precursor.

[0038] (3) The hollow carbon sphere micro-nano ...

Embodiment 2

[0043] A method for preparing hollow carbon sphere micro-nano aggregates, comprising the following steps:

[0044] (1) Add 15ml of tetraethyl orthosilicate to a mixed solvent of 10ml of ammonia, 200ml of ethanol, and 10ml of water under magnetic stirring, stir at 30°C for 10min, then add 10ml of resorcinol in ethanol ( Containing 1.44g resorcinol), 2.12g formaldehyde aqueous solution (mass fraction of formaldehyde is 37wt%), continue to stir for 12h, then react at 80°C-120°C for 12h-24h, separate the solid-liquid of the obtained product, and obtain yellow phenolic aldehyde Resin-coated silica nanosphere powder.

[0045] (2) Disperse 2.0 g of phenolic resin-coated silica nanosphere powder in 20 ml of water, ultrasonicate for 3 h, then add 10 g of an aqueous solution of polyurethane adhesive with a solid content of 10% to the above dispersion and stir evenly, 100 °C until evaporated to dryness to obtain a hollow carbon sphere micro-nano structure precursor.

[0046] (3) The ho...

Embodiment 3

[0050] A method for preparing a hollow carbon sphere micro-nano aggregate / sulfur composite material, comprising the following steps:

[0051] (1) Add 15ml of tetraethyl orthosilicate to a mixed solvent of 10ml of ammonia, 200ml of ethanol, and 10ml of water under magnetic stirring, stir at 30°C for 10min, then add 10ml of resorcinol in ethanol ( Containing 1.44g resorcinol), 2.12g formaldehyde aqueous solution (mass fraction of formaldehyde is 37wt%), continue to stir for 12h, then react at 80°C-120°C for 12h-24h, separate the solid-liquid of the obtained product, and obtain yellow phenolic aldehyde Resin-coated silica nanosphere powder.

[0052] (2) Disperse 2.0g of phenolic resin-coated silica nanosphere powder in 20ml of water, ultrasonicate for 3h, and then add 10g of LA133 (multi-component polyacrylonitrile copolymer water-based adhesive) solution with a solid content of 10% dropwise into the Stir in the above dispersion liquid evenly, and stir at 80° C. until evaporated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com