Black phosphorus and gelatin based composite hydrogel and application thereof to bone tissue engineering

A composite hydrogel and gelatin technology, applied in tissue regeneration, medical science, prostheses, etc., can solve the problems of harm to the body, slow bone repair process, low dynamic matching degree, etc., achieve good mechanical properties, promote the formation, The effect of high-intensity biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1 Preparation of black phosphorus-gelatin composite hydrogel

[0064] 1. A composite hydrogel based on black phosphorus and gelatin, prepared by the following steps:

[0065] (1) Preparation of black phosphorus nanosheets: black phosphorus was ground in N-methylpyrrolidone for 10 min, ultrasonically treated for 10 h at 1000 W, centrifuged at 8000 r / min for 10 min, and the supernatant was taken at 15000 r / min / min centrifugation, the resulting precipitated part is black phosphorus nanosheets, and its diameter is 250-300 nm;

[0066] (2) Preparation of pre-polymerization solution: gelatin with a molecular weight of 10000 was methacrylated and then dissolved in pure water to prepare a 10% methacrylated gelatin solution, and 0.17% (w / v) of DMSO was added Photoinitiator I2959, mix well to get the pre-polymerization solution;

[0067] Among them, the method for methacrylated gelatin is as follows: gelatin with a molecular weight of 10,000 is dissolved in PBS buffer ...

Embodiment 2

[0069] Embodiment 2 performance test

[0070] 1. Carry out performance detection to the composite hydrogel of the present invention

[0071] (1) if figure 1 As shown, the hydrogel prepared by the present invention has a complete shape, is transparent, and has good mechanical properties, and the hydrogel formed at the same time shows different shades of silvery black according to the content of black phosphorus.

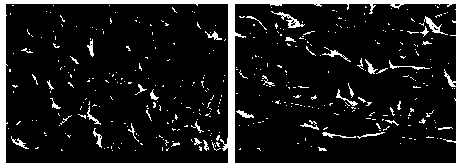

[0072] (2) if figure 2 It can be seen from the SEM images that the hydrogel prepared by the present invention has a good pore structure, which can provide a suitable growth space for bone cells, and the bone cells can adhere and grow well, facilitating the growth and reproduction of cells.

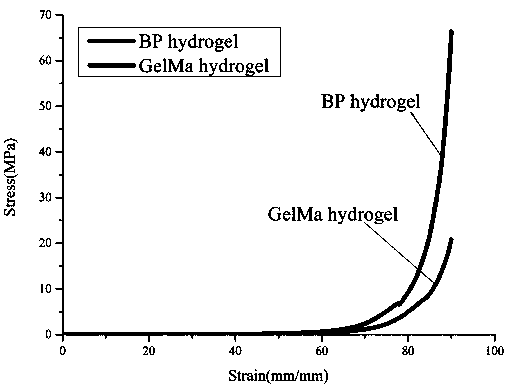

[0073] (3) if image 3 As shown, the mechanical performance test proves that under the same conditions, the pressure bearing capacity of the composite hydrogel (BPhydrogel) containing black phosphorus is significantly better than that of the composite hydrogel group (GelMa hyd...

Embodiment 3

[0083] Example 3 Adding Arg-UPEA to black phosphorus-gelatin composite hydrogel

[0084] The other conditions of the preparation method are the same as in Example 1, the only difference is that: in step (3) of the preparation method of the composite hydrogel, 2% (w / v) of arginine-based Unsaturated polyester amide (Arg-UPEA), dissolved and mixed with black phosphorus nanosheets, so that the black phosphorus content is 0.001%.

[0085] The results found that both the composite hydrogel without Arg-UPEA and the composite hydrogel with Arg-UPEA had good biocompatibility and osteogenic ability; compared with the composite hydrogel without Arg-UPEA , the black phosphorus and gelatin-based composite hydrogel added Arg-UPEA further improved the controlled release ability of black phosphorus, the reason may be that the chargeability of Arg-UPEA enhanced the interaction between cells.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com