Steel mill integrated sewage treatment system with low dosage and high recovery rate and treatment method thereof

A sewage treatment system with high recovery rate technology, applied in neutralization water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of many coagulants, low wastewater recovery rate and high cost , to achieve the effect of reducing the degree of corrosion, reducing the consumption of medicine and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

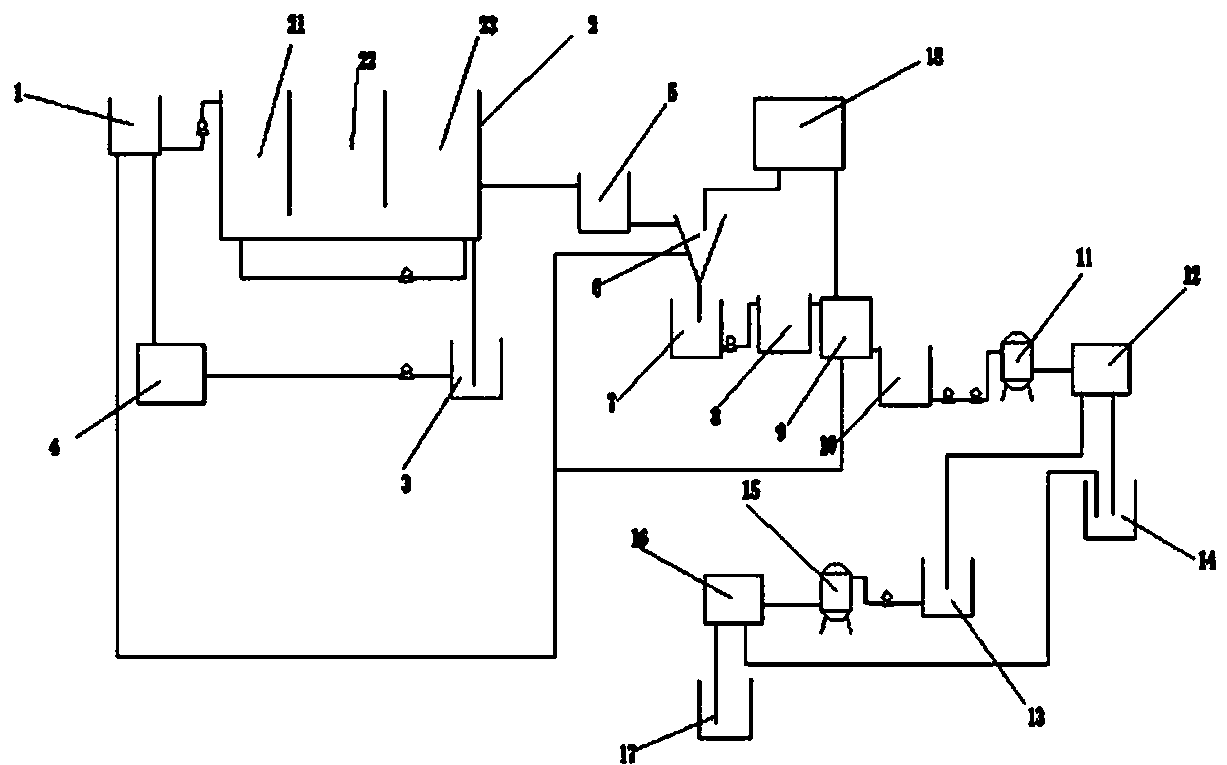

[0020] Embodiment 1: as figure 1 As shown, the comprehensive sewage treatment system of a steel plant with low dosage and high recovery rate includes a regulating tank 1, a high-efficiency sedimentation device 2, a neutralization reaction tank 5, a V-shaped filter tank 6, an intermediate tank 7, a self-cleaning filter 8, Ultrafiltration device 9, ultrafiltration water tank 10, No. 1 security filter 11, No. 1 reverse osmosis device 12, No. 1 thick water tank 13, reuse water tank 14, No. 2 concentration device, sludge dehydration device 4, backwashing device 18 , regulating tank 1, high-efficiency sedimentation device 2, neutralization reaction tank 5, V-shaped filter tank 6, intermediate tank 7, self-cleaning filter 8, ultrafiltration device 9, ultrafiltration water tank 10, No. 1 security filter 11, The No. 1 concentration device 12 and the reuse water pool 14 are sequentially connected through pipelines. The No. 1 reverse osmosis device 12 is provided with a No. 1 concentrate...

Embodiment 2

[0021] Example 2: During operation, steel plant raw material area, sintering area, pelletizing area, blast furnace area, oxygen production area, steelmaking, continuous casting area, wire bar area, power plant area (including demineralized water station), softened water station After the sewage and wastewater in the whole site, such as public and auxiliary areas, are uniform in water quality and quantity in the adjustment pool 1, the raw water pump is pressurized and lifted into the rapid mixing pool 21 in the high-efficiency sedimentation device, and then lime or soda ash is added to adjust the pH to 9-10.5. Add polyaluminum chloride for coagulation and precipitation, the dosage of polyaluminum chloride is 10-20kg / 1,000 tons of wastewater; the water after coagulation and precipitation enters the flocculation reaction tank 22 in the high-efficiency sedimentation device to flocculate with polyacrylamide reaction, the dosage of polyacrylamide is 20-50kg / 1000 tons of wastewater, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com