Energy-storage light-emitting coating and preparation method thereof

An energy-storing luminescent and energy-storing luminescent powder technology, applied in the field of coatings, can solve the problems of reducing the luminous brightness of the coating, easy agglomeration or sedimentation, and reducing the adhesion between the coating and the substrate, so as to improve the luminous intensity and resist adverse environments. The effect of improving energy storage luminous performance and weather resistance, improving adhesion and stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] An energy-storing luminous paint, comprising the following components in mass percentage:

[0054]

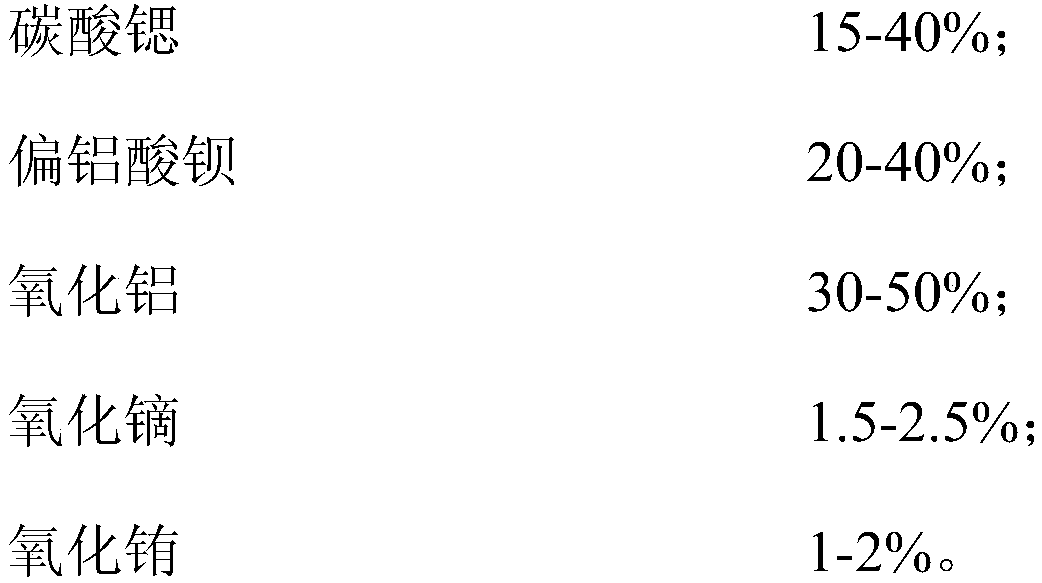

[0055] Among them, the energy storage luminescent powder is composed of the following components in mass percentage:

[0056]

[0057] The preparation method of the above-mentioned energy storage luminous coating is as follows:

[0058] (1) Dissolve polyamide wax in n-butanol, mix with energy storage luminescent powder, and then ball mill for 1 hour;

[0059] (2) drying the slurry obtained in step (1) at 100° C. in a vacuum environment to obtain a coated energy-storage luminescent powder;

[0060] (3) Mix the coated energy-storage luminescent powder obtained in step (2) with the water-based resin and water to obtain the energy-storage luminescent paint.

Embodiment 2

[0062] An energy-storing luminous paint, comprising the following components in mass percentage:

[0063]

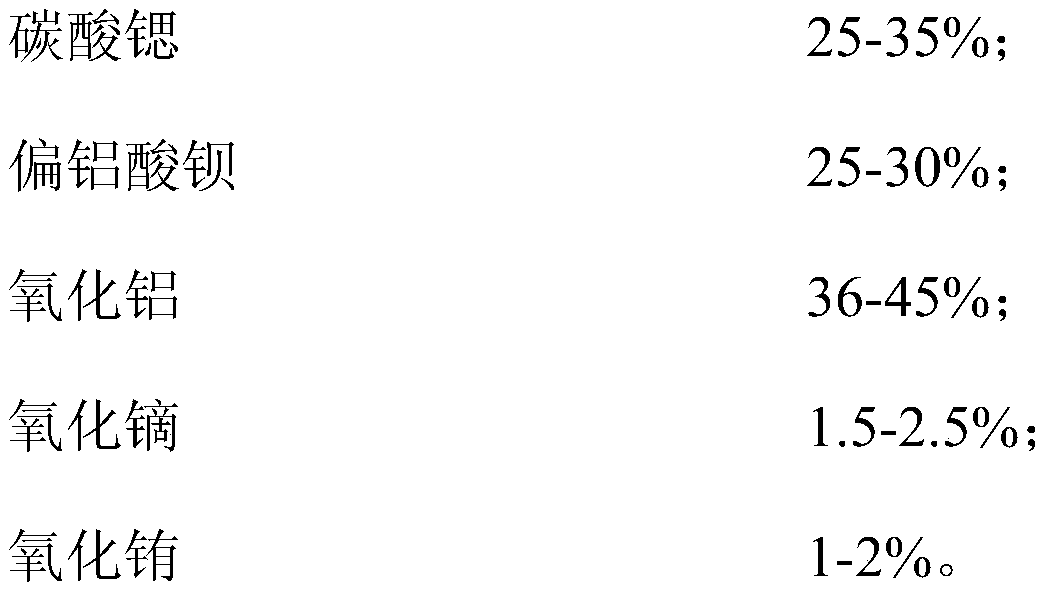

[0064] Among them, the energy storage luminescent powder is composed of the following components in mass percentage:

[0065]

[0066] The preparation method of the above-mentioned energy storage luminous coating is as follows:

[0067] (1) Dissolve polyamide wax in n-butanol, mix with energy storage luminescent powder, and then ball mill for 1.5h;

[0068] (2) drying the slurry obtained in step (1) at 105° C. in a vacuum environment to obtain a coated energy-storage luminescent powder;

[0069] (3) Mix the coated energy-storage luminescent powder obtained in step (2) with the water-based resin and water to obtain the energy-storage luminescent paint.

Embodiment 3

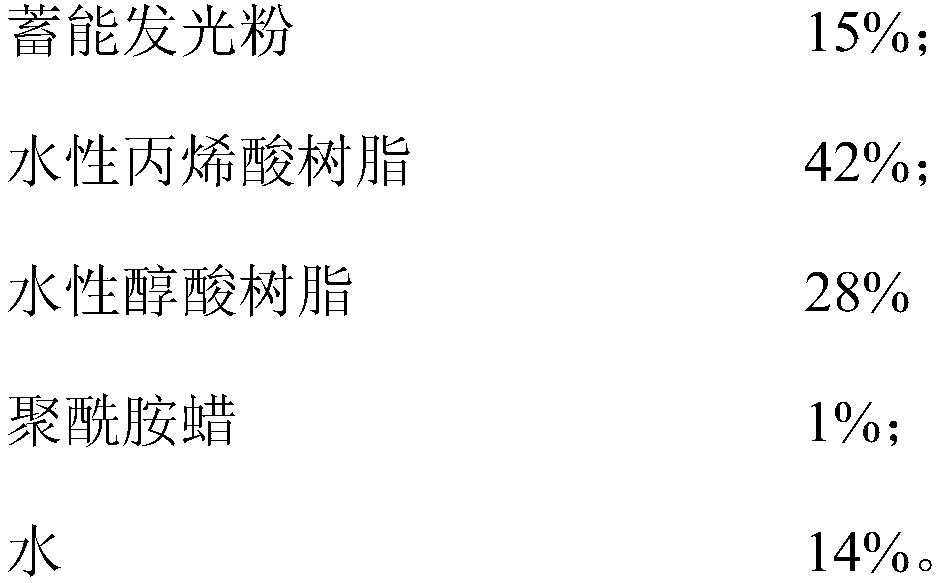

[0071] An energy-storing luminous paint, comprising the following components in mass percentage:

[0072]

[0073]

[0074] Among them, the energy storage luminescent powder is composed of the following components in mass percentage:

[0075]

[0076] The preparation method of the above-mentioned energy storage luminous coating is as follows:

[0077] (1) Dissolve polyamide wax in n-butanol, mix with energy storage luminescent powder, and then ball mill for 2 hours;

[0078] (2) drying the slurry obtained in step (1) at 110° C. in a vacuum environment to obtain a coated energy-storage luminescent powder;

[0079] (3) Mix the coated energy-storage luminescent powder obtained in step (2) with the water-based resin and water to obtain the energy-storage luminescent paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com