Cobalt disulfide nanocrystal / graphene composite electrode material and preparation method thereof

A graphene composite and cobalt disulfide technology, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc., can solve the problem of affecting catalytic characteristics and energy storage cycle stability, active sites cannot be fully exposed, Iron disulfide decomposition acceleration and other issues, to achieve the effect of improving electrochemical performance, high production efficiency, and uniform material distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

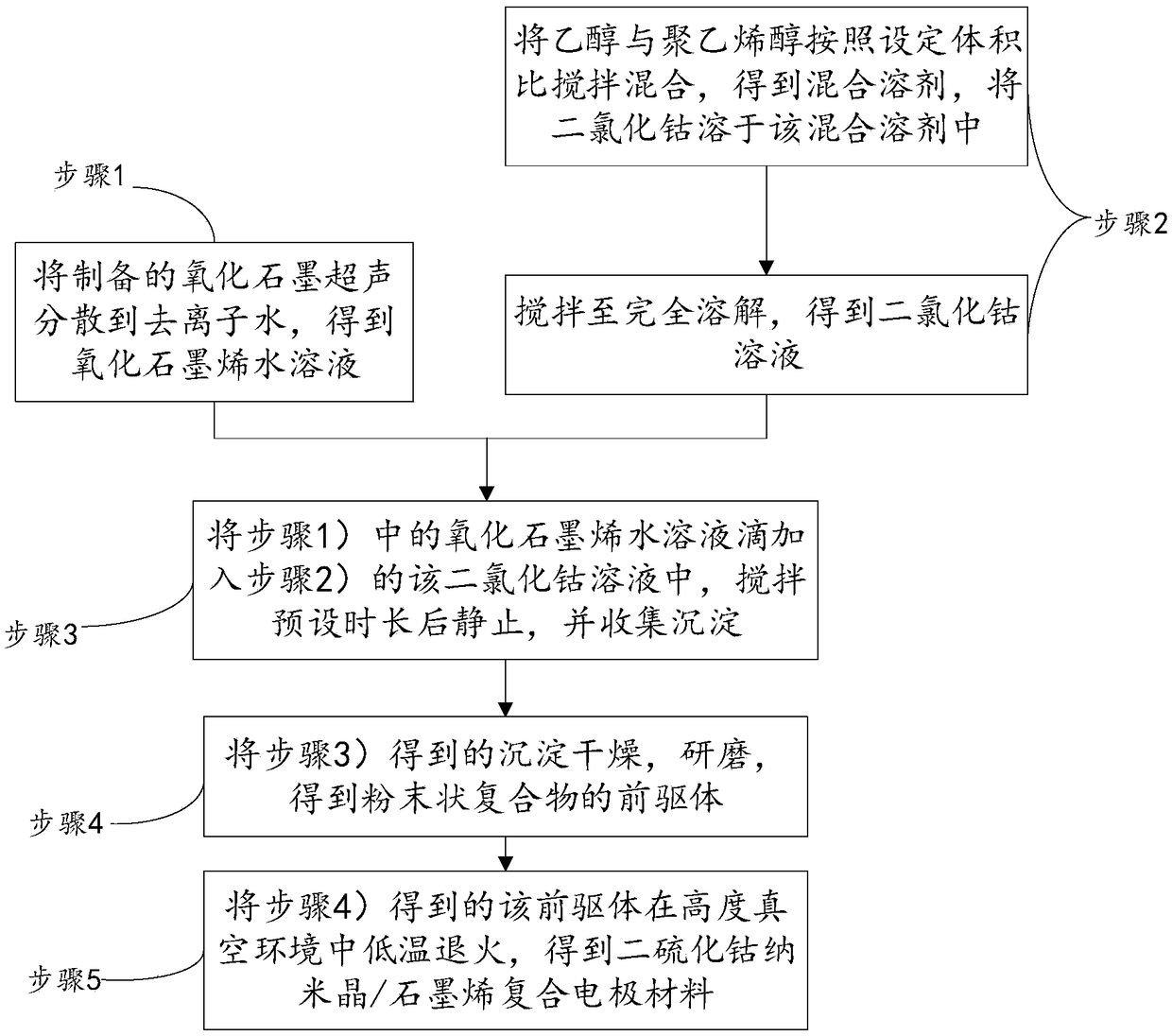

Embodiment 1

[0036] This embodiment relates to a method for preparing a cobalt disulfide nanocrystal / graphene composite electrode material. An electrode material composed of cobalt disulfide nanocrystal grains and graphene with a size of 1-10 nanometers is prepared by vacuum low-temperature calcination. The preparation method of the composite electrode material composites cobalt disulfide nano crystal grains and single-layer graphene. The graphene is a single layer of graphite, which is composed of hexagonal arrangement of carbon atoms, has high internal carrier mobility, good thermal conductivity, high specific surface area, and excellent mechanical strength. Due to the strong π-π interaction between graphene sheets, the sheets are easily re-stacked to form a graphite-like structure. Pure cobalt disulfide has low resistivity, good catalytic activity and chemical stability, but it is prone to self-agglomeration, and the active sites cannot be fully exposed, which affects its catalytic prop...

Embodiment 1

[0054] The cobalt disulfide nanocrystal / graphene composite electrode material was prepared with the mass ratio of graphene oxide to cobalt dichloride being 3:1.

[0055] Stir and mix absolute ethanol and polyvinyl alcohol at a volume ratio of 6:1 to obtain a mixed solution. Take 2 ml of the mixed solution, then dissolve 0.04 g of cobalt dichloride in the mixed solution, stir evenly, and slowly add 10 ml of graphene oxide dropwise, for example, the concentration of graphene oxide is: 3 mg / ml. Stir ultrasonically for 1 hour, stand still, collect the precipitate by centrifugation, wash several times with deionized water, for example three times, and freeze-dry to obtain the composite precursor. Finally, under a vacuum environment of 40 Pascals, the temperature was kept at 350° C. for 0.5 hours to obtain a cobalt disulfide nanocrystal / graphene composite electrode material.

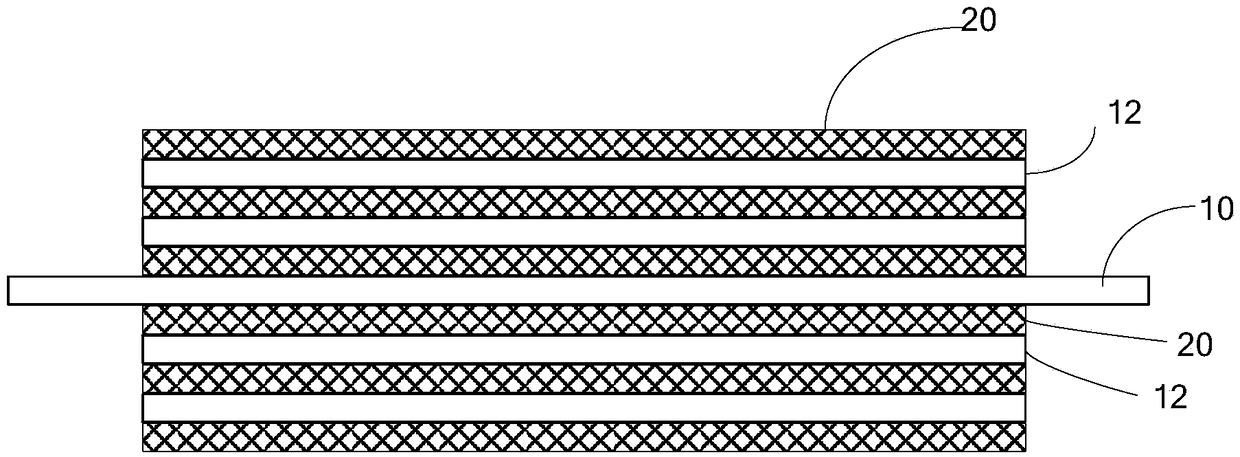

[0056] Add carbon black and adhesive to the collected product, grind and mix evenly, apply the slurry on c...

Embodiment 2

[0058] The cobalt disulfide nanocrystal / graphene composite electrode material was prepared with the mass ratio of graphene oxide to cobalt dichloride being 5:1.

[0059] Stir and mix absolute ethanol and polyvinyl alcohol at a volume ratio of 1:1, and take 4 ml of the mixed solution. Then 0.2 g of cobalt dichloride was dissolved in the mixed solution, and after stirring for 5 hours, 40 ml of graphene oxide was slowly added dropwise, for example, the concentration of graphene oxide was: 25 m g / ml, stirred ultrasonically for 2 hours, and stood still. The precipitate was collected by centrifugation, washed three times with deionized water, and dried in vacuum to obtain the composite precursor. Finally, under a vacuum atmosphere of 10 Pascals, the temperature was kept at 300° C. for 2 hours to obtain a cobalt disulfide nanocrystal / graphene composite electrode material.

[0060] Add carbon black and adhesive to the collected product, grind and mix evenly, apply the slurry on coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com