Boron tailings planting soil and preparation method thereof

A technology of tailings and boron mud, applied in the directions of botanical equipment and methods, clay products, planting substrates, etc., can solve problems such as environmental pollution, reduce the occupation of land resources and pollute the environment, improve the utilization rate, reduce alkali return and The effect of the burst problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

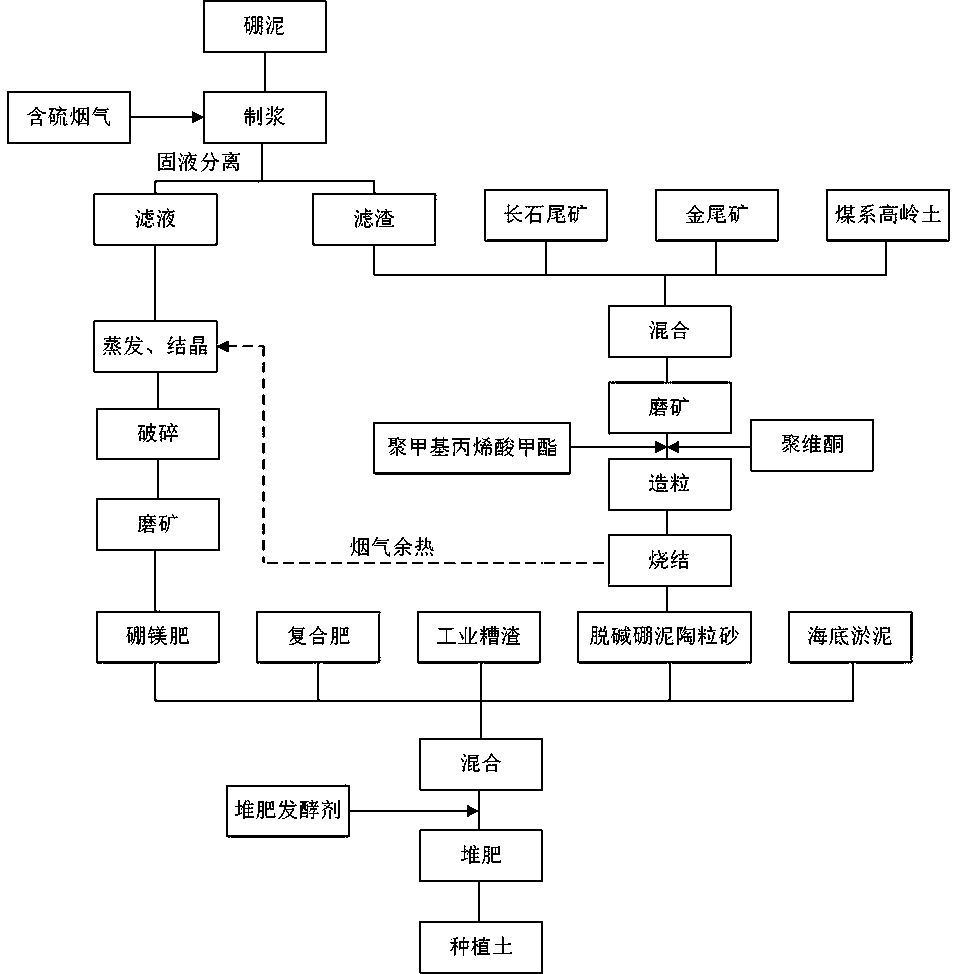

Method used

Image

Examples

Embodiment 1

[0029] (1) Configure the boron mud into a slurry with a solid-to-liquid ratio of 6:1, and feed it into the slurry with a flow rate of 3.2m 3 / h sulfur-containing flue gas. After fully reacting, the slurry is subjected to solid-liquid separation to obtain the filtrate and filter residue. The filtrate is evaporated and crystallized by waste heat of the flue gas, crushed by a cone crusher, and ground by a rod mill to make a particle size of 0.1 mm boron magnesium fertilizer;

[0030] (2) Feed the dealkalized boron mud, feldspar tailings, gold tailings, and coal series kaolin into the ball mill for grinding according to the mass ratio of 62:15:15:8, and obtain a mixture of -200 mesh accounting for 95% Tailings powder, then mix the mixed tailings powder: polymethyl methacrylate and povidone according to the mass ratio of 90:5:5, and then granulate it through a tooth-stirring granulator to obtain particles smaller than 2mm. The particles were fired at a high temperature of 1100°C i...

Embodiment 2

[0035] (1) Boron mud is configured into a slurry with a solid-to-liquid ratio of 6.3:1, and a flow rate of 3.4 m is passed into the slurry 3 / h sulfur-containing flue gas. After fully reacting, the slurry is subjected to solid-liquid separation to obtain the filtrate and filter residue. The filtrate is evaporated and crystallized by waste heat of the flue gas, crushed by a cone crusher, and ground by a rod mill to make a particle size of 0.5 mm boron magnesium fertilizer;

[0036] (2) Feed dealkalized boron mud, feldspar tailings, gold tailings, and coal-based kaolin into a ball mill for grinding in a mass ratio of 65:13:15:7 to obtain a mixture of -200 mesh accounting for 95% Tailings powder, then mix the mixed tailings powder: polymethyl methacrylate and povidone according to the mass ratio of 95:2:3, and then granulate it through a tooth-stirring granulator to obtain particles smaller than 2mm. The particles were fired at a high temperature of 1100°C in a waterfall rotary ...

Embodiment 3

[0041] (1) Boron mud is configured into a slurry with a solid-to-liquid ratio of 6.5:1, and a flow rate of 3.5 m is introduced into the slurry 3 / h sulfur-containing flue gas. After fully reacting, the slurry is subjected to solid-liquid separation to obtain the filtrate and filter residue. The filtrate is evaporated and crystallized by waste heat of the flue gas, crushed by a cone crusher, and ground by a rod mill to make a particle size of 1mm. boron magnesium fertilizer;

[0042] (2) Feed dealkalized boron mud, feldspar tailings, gold tailings, and coal series kaolin into the ball mill for grinding at a mass ratio of 70:13:10:7 to obtain a mixture of -200 mesh accounting for 95% Tailings powder, then mix the mixed tailings powder: polymethyl methacrylate and povidone according to the mass ratio of 92:3:5, and then granulate through a tooth-stirring granulator to obtain particles smaller than 2mm. The particles were fired at a high temperature of 1100°C in a waterfall rotar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com