Injection-type high-strength degradable porous magnesium phosphate bone repairing material

A magnesium phosphate bone and repair material technology, applied in the field of medical materials, can solve problems such as poor osseointegration and bone ingrowth, and achieve the effects of promoting bone ingrowth, guiding bone growth, and reducing thermal damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

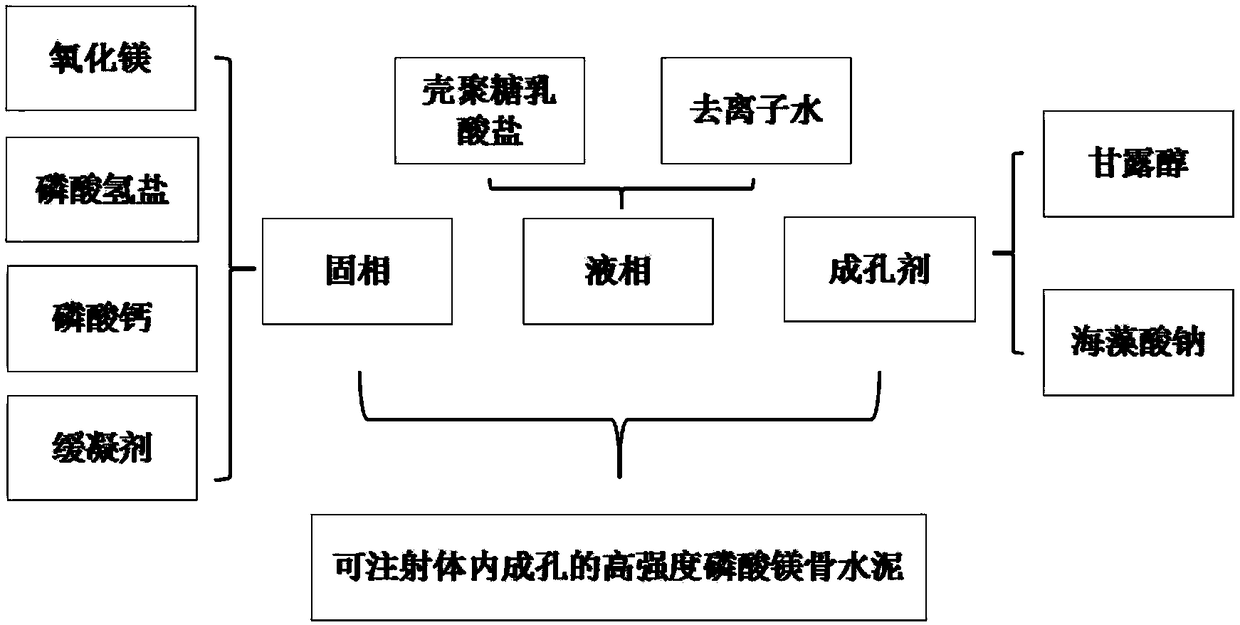

[0029] An injection-type high-strength degradable porous magnesium phosphate bone repair material, its process flow diagram is shown in figure 1 , the specific preparation steps are as follows:

[0030] 1) Mix 100 parts (parts by weight, the same below) of sintered magnesium oxide powder, 400 parts of phosphate, 50 parts of calcium phosphate, and 20 parts of retarder (10 parts each of L-lysine and L-tryptophan) , to obtain the solid phase of magnesium phosphate bone cement;

[0031] 2) adding chitosan lactate into deionized water, preparing a water-soluble chitosan solution with a concentration of 10 wt%, shaking evenly to obtain a liquid phase;

[0032] 3) mixing mannitol crystals and sodium alginate in a mass ratio of 1:2 to obtain a pore-forming agent;

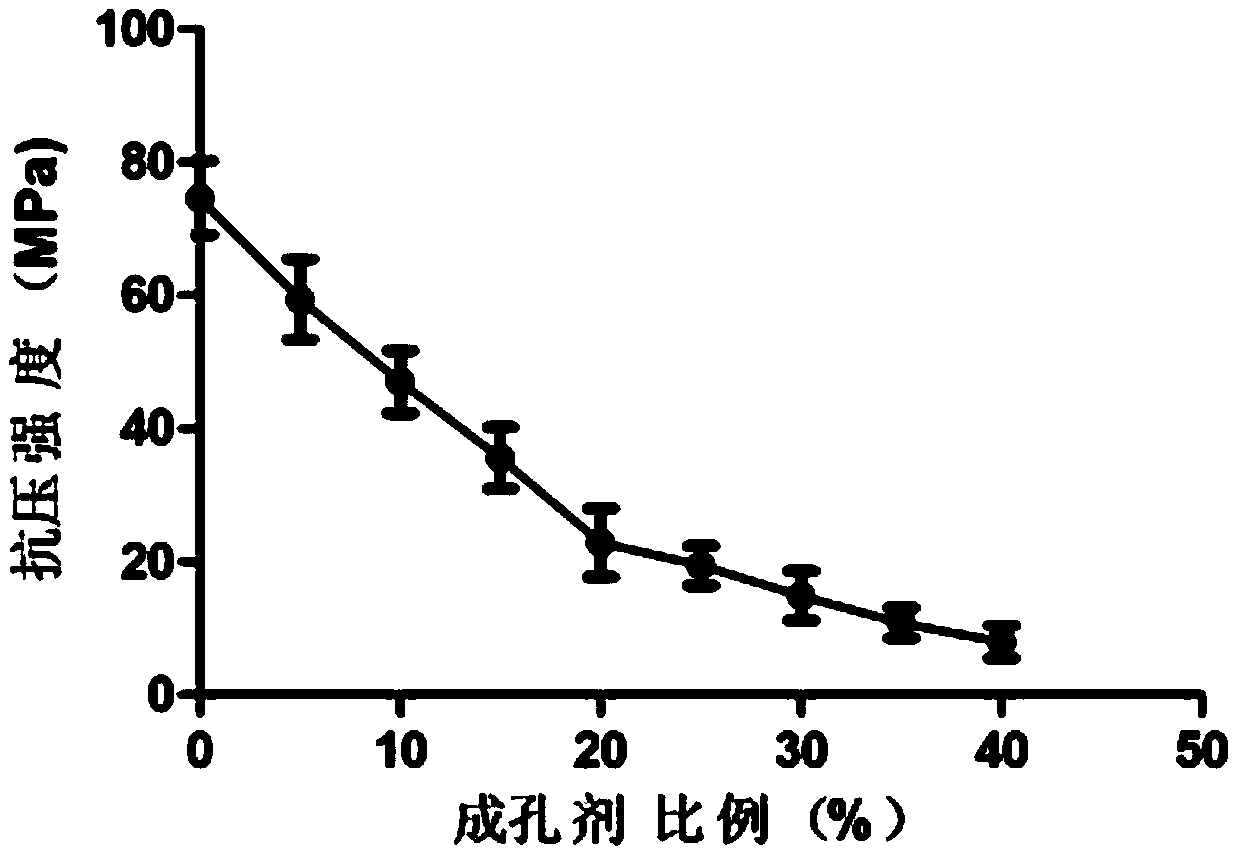

[0033] 4) First add a pore-forming agent in the solid phase, and the amount of the pore-forming agent added is 10% of the solid phase mass; then according to the solid-liquid ratio of 1g / ml (the solid-liquid ratio refers ...

Embodiment 2

[0038] The preparation method of the porous magnesium phosphate bone repair material described in this embodiment is roughly the same as in Example 1, except that the solid phase in step 1) consists of 100 parts of sintered magnesium oxide powder, 400 parts of phosphate, 50 parts of calcium phosphate, 40 parts of retarder (20 parts each of L-lysine and L-tryptophan) are mixed, the concentration of chitosan lactate solution is 15wt%, and the pore forming agent consists of mannitol crystals and sodium alginate 2 : 1 mass ratio mixed, the amount of pore forming agent added is 15% of the solid phase mass, and the solid-to-liquid ratio is 2g / ml.

[0039] The final setting time of the porous magnesium phosphate bone repair material obtained in this example is 17.5 minutes; the highest reaction temperature is 43.7° C.; the compressive strength is 43.6 MPa; the porosity is 29.5%.

Embodiment 3

[0041] The preparation method of the porous magnesium phosphate bone repair material described in this embodiment is roughly the same as in Example 1, except that the solid phase in step 1) consists of 100 parts of sintered magnesium oxide powder, 400 parts of phosphate, 50 parts of calcium phosphate, 40 parts of retarder (20 parts each of L-lysine and L-tryptophan) are mixed, the concentration of chitosan hydrochloride solution is 15wt%, and the pore-forming agent consists of mannitol crystals and sodium alginate 1 : 1 mass ratio mixed, the amount of pore forming agent added is 20% of the solid phase mass, and the solid-to-liquid ratio is 2g / ml.

[0042]The final setting time of the porous magnesium phosphate bone repair material obtained in this example was 18.4 minutes; the highest reaction temperature was 44.8° C.; the compressive strength was 37.8 MPa; the porosity was 33.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Final setting time | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com