Edible packaging membrane with good barrier function and preparation method of edible packaging membrane

A high-barrier, packaging film technology, used in sustainable packaging, packaging, wrapping paper, etc., can solve the problems of easy deliquescence, spoilage, poor mechanical properties, and low network density, and achieve good biological phase. Capacitance and degradability, enhanced mechanical properties, good heat sealability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

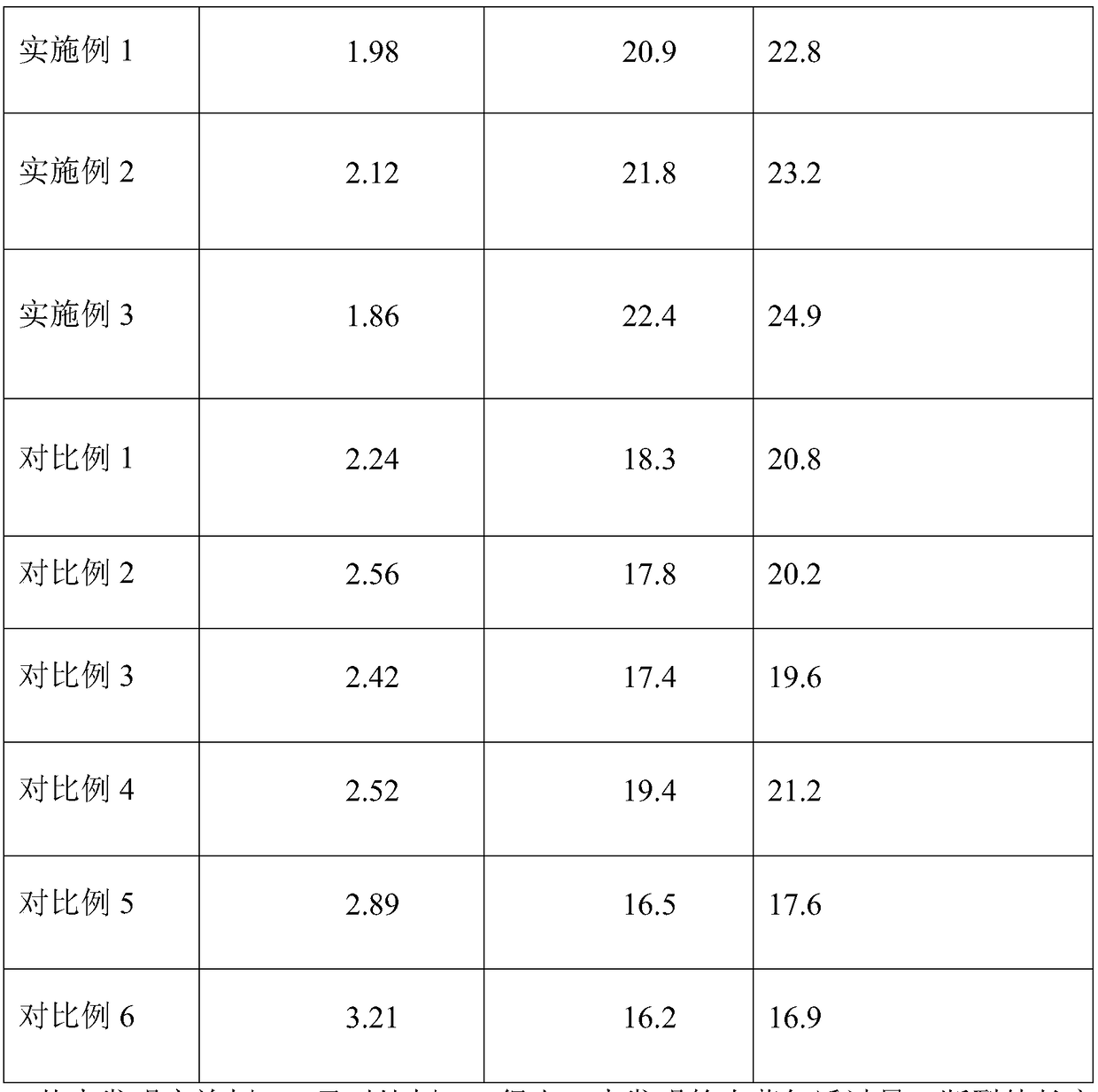

Embodiment 1

[0026] An edible packaging film with high barrier function of this embodiment includes the following raw materials:

[0027] Modified cross-linked starch, gelatin, powdered cellulose, pentaerythritol phthalate, barrier enhancer, isoamyl acetate;

[0028] The modified cross-linked starch includes the following raw materials by weight: 32 parts of cross-linked starch, 24 parts of watermelon rind nanocellulose, 14 parts of carrageenan, 6 parts of ethyl cellulose aqueous suspension, 4 parts of maltitol, and magnesium aluminum silicate 2 parts, 1 part talcum powder, 14 parts deionized water;

[0029] The cross-linked starch is wheat starch and corn starch, which uses sodium hexametaphosphate as a cross-linking agent and sodium hydroxide as a catalyst to obtain cross-linked starch;

[0030] The preparation method of the watermelon rind nanocellulose is to wash the watermelon rind with clean water, and then cut into pieces of uniform size, and then send them to a drying box for drying, dryin...

Embodiment 2

[0043] An edible packaging film with high barrier function of this embodiment includes the following raw materials:

[0044] Modified cross-linked starch, gelatin, powdered cellulose, pentaerythritol phthalate, barrier enhancer, isoamyl acetate;

[0045] The modified cross-linked starch includes the following raw materials by weight: 38 parts of cross-linked starch, 30 parts of watermelon rind nanocellulose, 18 parts of carrageenan, 12 parts of ethyl cellulose aqueous suspension, 8 parts of maltitol, and magnesium aluminum silicate 5 parts, 3 parts talc, 20 parts deionized water;

[0046] The cross-linked starch is wheat starch and corn starch, which uses sodium hexametaphosphate as a cross-linking agent and sodium hydroxide as a catalyst to obtain cross-linked starch;

[0047] The preparation method of the watermelon rind nanocellulose is to wash the watermelon rind with clean water, then cut into pieces of uniform size, and then send it to a drying box for drying, drying for 25 minu...

Embodiment 3

[0060] An edible packaging film with high barrier function of this embodiment includes the following raw materials:

[0061] Modified cross-linked starch, gelatin, powdered cellulose, pentaerythritol phthalate, barrier enhancer, isoamyl acetate;

[0062] The modified cross-linked starch includes the following raw materials by weight: 35 parts of cross-linked starch, 27 parts of watermelon rind nanocellulose, 16 parts of carrageenan, 9 parts of ethyl cellulose aqueous suspension, 6 parts of maltitol, magnesium aluminum silicate 3.5 parts, 2 parts talcum powder, 17 parts deionized water;

[0063] The cross-linked starch is wheat starch and corn starch, which uses sodium hexametaphosphate as a cross-linking agent and sodium hydroxide as a catalyst to obtain cross-linked starch;

[0064] The preparation method of the watermelon rind nanocellulose is to wash the watermelon rind with clean water, and then cut it into pieces of uniform size, and then send it to a drying box for drying, dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com