A kind of high-speed spinning nylon 6 chips and preparation method thereof

A high-speed spinning, nylon technology, used in rayon manufacturing, textile and papermaking, monocomponent polyamide rayon, etc. Processability, good effect of adjusting molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

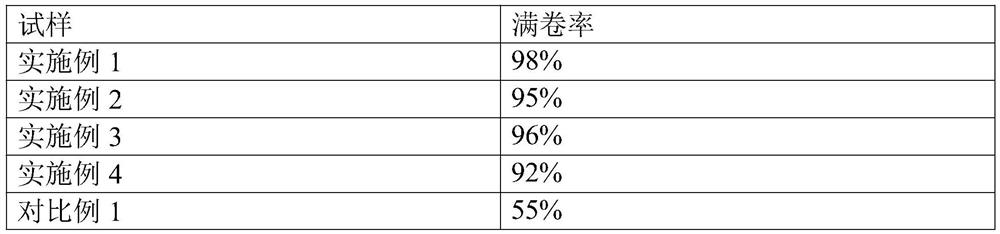

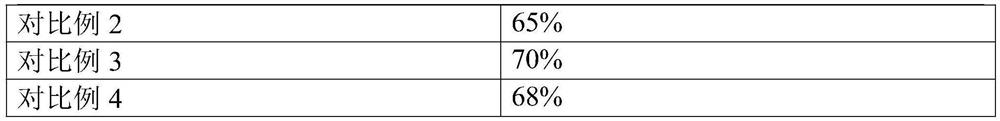

Examples

Embodiment 1

[0041] Embodiment 1: a kind of high-speed spinning nylon 6 chips, comprising the following materials in parts by weight:

[0042] Caprolactam 2300 parts;

[0043] 2 parts polycarbonate;

[0044] 1 part of titanium dioxide;

[0045] 1 part filler;

[0046] 2 parts toughening agent;

[0047] 1 part light stabilizer;

[0048] 3 parts of cross-linking agent;

[0049] 1 part of flame retardant;

[0050] 1 part antioxidant;

[0051] 7 parts of regulator;

[0052] Described conditioner comprises following material by weight:

[0053] 4 parts of 4,4-dimethyl-2,4-diphenyl-1-butene;

[0054] 2 parts of diisopropyl di(acetylacetonate) titanate;

[0055] 1 part of 3,3',5,5'-tetra-tert-butyldiphenolquinone;

[0056] 2 parts of polyethylene glycol mono-4-nonylphenyl ether;

[0057] 1 part of tris(dipropylene glycol) phosphite;

[0058] 2 parts of 2,2-dimethyl-1,3-propanediol.

[0059] The filler is a mixture of calcium carbonate and magnesium carbonate with a mass ratio of 2:1...

Embodiment 2

[0075] Embodiment 2: a kind of high-speed spinning nylon 6 chips, comprising the following materials in parts by weight:

[0076] Caprolactam: 2000 parts;

[0077] 1 part polycarbonate;

[0078] 2 parts of titanium dioxide;

[0079] 1 part filler;

[0080] 1 part of toughening agent;

[0081] 1 part light stabilizer;

[0082] 2 parts of crosslinking agent;

[0083] 1 part of flame retardant;

[0084] 1 part antioxidant;

[0085] 5 parts of regulator;

[0086] Described conditioner comprises following material by weight:

[0087] 4 parts of 4,4-dimethyl-2,4-diphenyl-1-butene;

[0088] 2 parts of diisopropyl di(acetylacetonate) titanate;

[0089] 1 part of 3,3',5,5'-tetra-tert-butyldiphenolquinone;

[0090] 2 parts of polyethylene glycol mono-4-nonylphenyl ether;

[0091] 1 part of tris(dipropylene glycol) phosphite;

[0092] 2 parts of 2,2-dimethyl-1,3-propanediol.

[0093] The filler is a mixture of calcium carbonate and magnesium carbonate with a mass ratio of 2...

Embodiment 3

[0109] Embodiment 3: a kind of high-speed spinning nylon 6 chips, comprising the following materials in parts by weight:

[0110] Caprolactam: 2500 parts;

[0111] 3 parts polycarbonate;

[0112] 1 part of titanium dioxide;

[0113] 2 parts filler;

[0114] 2 parts toughening agent;

[0115] 2 parts of light stabilizer;

[0116] 4 parts of crosslinking agent;

[0117] 1 part of flame retardant;

[0118] 1 part antioxidant;

[0119] 8 parts of regulator;

[0120] Described conditioner comprises following material by weight:

[0121] 4 parts of 4,4-dimethyl-2,4-diphenyl-1-butene;

[0122] 2 parts of diisopropyl di(acetylacetonate) titanate;

[0123] 1 part of 3,3',5,5'-tetra-tert-butyldiphenolquinone;

[0124] 2 parts of polyethylene glycol mono-4-nonylphenyl ether;

[0125] 1 part of tris(dipropylene glycol) phosphite;

[0126] 2 parts of 2,2-dimethyl-1,3-propanediol.

[0127] The filler is a mixture of calcium carbonate and magnesium carbonate with a mass ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com