A kind of homogeneous non-combustible polyurethane foam thermal insulation material and preparation method thereof

A polyurethane foam, thermal insulation technology, applied in the field of new materials, can solve the problems of difficult to achieve industrialized production, poor fire resistance, etc., and achieve the effects of good mechanical strength, good thermal insulation performance, and improved flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

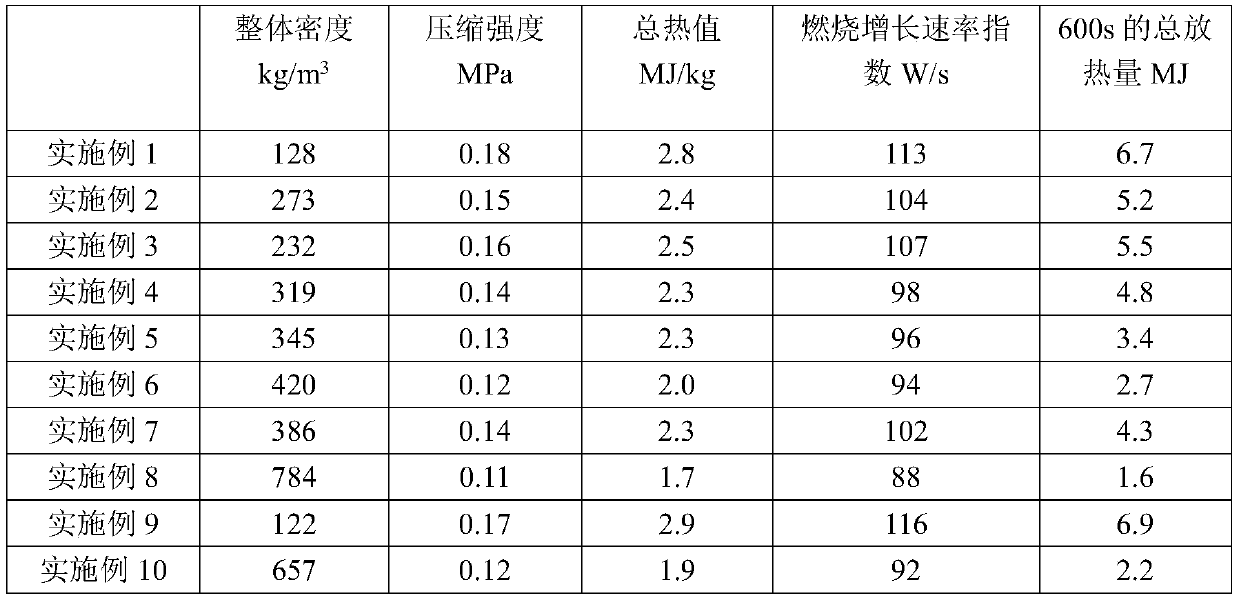

Examples

Embodiment 1

[0040] Flame retardant: by weight, get 140 parts of flame retardant (100 parts of red phosphorus, 40 parts of trimethyl phosphate);

[0041] Inorganic filler: in parts by weight, take 1020 parts of inorganic filler (940 parts of 150 mesh silica sand, 80 parts of 250 mesh perlite), the loose bulk density of inorganic filler is 1.6g / cm 3 .

[0042] Polyurethane rigid foam foaming material: by weight, white material: 100 parts of polyether polyol (H4110, Hongbaoli, 60 parts; HP3202, Hongbaoli, 30 parts; HP3201, Hongbaoli, 10 parts) , 23 parts of blowing agent (10 parts of cyclopentane, 13 parts of n-pentane), 4.2 parts of catalyst (1.4 parts of pentamethyl dimethylene triamine, 1.8 parts of dimethylcyclohexylamine, 2,4,6 - 1.0 parts of tris(dimethylaminomethyl)phenol), 2.2 parts of silicone surfactant (AK8830, Mester), 1.5 parts of water; black material: 158 parts of polyphenyl polymethylene polyisocyanate (M50, BASF). The weight ratio of white material to black material is 10...

Embodiment 2

[0046] Flame retardant: by weight, get 360 parts of flame retardant (200 parts of aluminum hydroxide, 100 parts of expanded graphite, 60 parts of trishydroxymethyl phosphine oxide);

[0047] Inorganic filler: by weight, take 1840 parts of inorganic filler (1320 parts of 200 mesh quartz sand, 160 parts of 100 mesh montmorillonite, 360 parts of 400 mesh limestone), the loose bulk density of inorganic filler is 1.5g / cm 3 .

[0048] Polyurethane rigid foam foaming material: by weight, white material: 100 parts of polyether polyol (HP2502, 60 parts of Hongbaoli; HP3201, 40 parts of Hongbaoli), 34 parts of foaming agent (HFC-365mfc 14 parts, HFC-245fa 20 parts), catalyst 2.2 parts (N-methylmorpholine 0.6 parts, dimethylbenzylamine 1.2 parts, quaternary ammonium salt TMR-20.4 parts), silicone surfactant 0.5 parts (Niax L- 5440, Momentive), 3.0 parts of water, mixed evenly; black material: 224 parts of polyphenyl polymethylene polyisocyanate (PM100, Wanhua). The weight ratio of whit...

Embodiment 3

[0052] Flame retardant: by weight, take 420 parts of flame retardant (200 parts of antimony trioxide, 160 parts of zinc borate, 40 parts of tricumyl phosphate, 20 parts of triphenyl phosphate);

[0053] Inorganic filler: by weight, take 1460 parts of inorganic filler (1100 parts of 120 mesh slag, 290 parts of 300 mesh calcite, 70 parts of 1000 mesh diatomite), the loose bulk density of inorganic filler is 1.4g / cm 3 .

[0054] Polyurethane rigid foam foaming material: by weight, white material: 80 parts of polyether polyol (H4110, Hongbaoli, 60 parts; HP3201, Hongbaoli, 20 parts), polyester polyol 20 parts (PS -2502, Stepan), 26 parts of foaming agent (16 parts of cyclopentane, 10 parts of HFC-365mfc), 1.5 parts of catalyst (0.2 part of dibutyltin dilaurate, 0.8 part of dimethylcyclohexylamine, trihexahydrogen 0.5 parts of oxazine), 1.8 parts of silicone surfactant (B8486, Degussa), 2.0 parts of water, mix well; black material: 185 parts of polyphenyl polymethylene polyisocyan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com