Pre-separation method for ethanediol and 1,2-butanediol-containing raw material and preparation method of epoxybutane

A technology of butylene oxide and ethylene glycol, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve problems such as large amount of waste water, difficult product separation, large investment, etc., to achieve The effect of low equipment investment cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

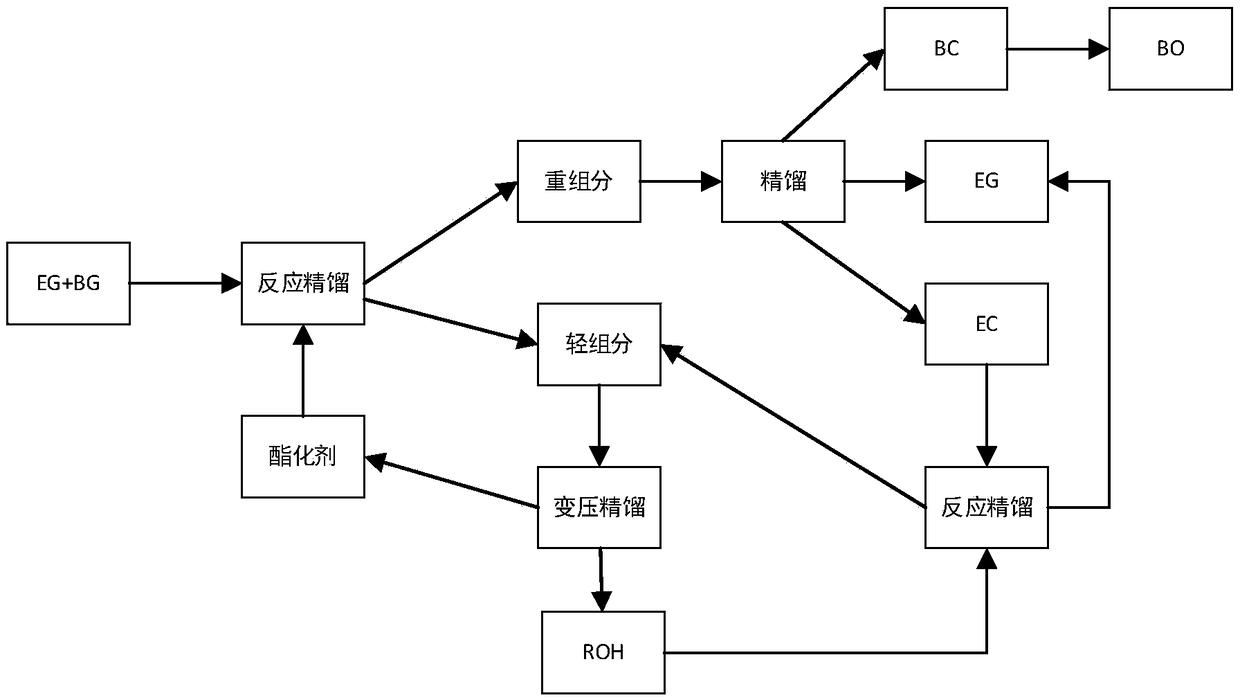

[0071] see figure 1 , is a schematic flow chart of a method for preparing butylene oxide in one embodiment, and the corresponding method for preparing butylene oxide includes the following steps S210 to S260:

[0072] S210, reacting and rectifying the raw material containing ethylene glycol and 1,2-butanediol and the esterification esterification agent under the action of a catalyst to obtain the light component of the corresponding reaction product containing the esterification agent and the light component containing ethylene carbonate and carbonic acid Heavy component of butenyl esters.

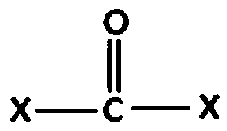

[0073] Wherein, the structural general formula of esterifying agent is as follows:

[0074]

[0075] In this structural formula, X is Cl, NH 2 Or OR, R is a C1-C4 linear or branched alkyl group.

[0076] That is, the esterification agent is phosgene, urea, dimethyl carbonate, diethyl carbonate, dipropyl carbonate, dibutyl carbonate, etc., which are not listed here, as long as the abo...

Embodiment 1

[0113] Reactive distillation of raw materials containing 95% ethylene glycol and 5% 1,2-butanediol and dimethyl carbonate under the action of sodium methoxide to obtain light components containing methanol and dimethyl carbonate and ethylene carbonate And the heavy component of butylene carbonate, wherein the top temperature of reactive distillation is 64°C, the kettle temperature is 100°C, the number of plates is 50, the absolute pressure is 1Bar, and the mol ratio of dimethyl carbonate and mixed alcohol in the raw material is 1.3:1, The molar ratio of sodium methoxide to mixed alcohol in the raw material is 0.01:1.

[0114] After the heavy components containing ethylene carbonate and butylene carbonate are subjected to primary rectification, high-purity ethylene glycol is extracted from the top of the tower, and a mixture of ethylene carbonate, butylene carbonate and sodium methylate is extracted from the bottom of the tower. The above-mentioned mixture of ethylene carbonate...

Embodiment 2

[0120] The raw material containing 40% ethylene glycol and 60% 1,2-butanediol and diethyl carbonate are subjected to reactive distillation under the action of tetrabutyl titanate to obtain light components containing ethanol and diethyl carbonate and The heavy components of ethylene carbonate and butylene carbonate, wherein the top temperature of reactive distillation is 90°C, the kettle temperature is 130°C, the number of trays is 69, the absolute pressure is 1Bar, and the molar ratio of diethyl carbonate to mixed alcohol in the raw material is 4 :1, the molar ratio of tetrabutyl titanate to the mixed alcohol in the raw material is 0.05:1.

[0121] After the heavy components containing ethylene carbonate and butylene carbonate are subjected to primary rectification, high-purity ethylene glycol is extracted from the top of the tower, and ethylene carbonate, butylene carbonate and tetrabutyl titanate are extracted from the bottom of the tower The mixture of ethylene carbonate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com