Special color carbon black dye and preparation method thereof

A pigment carbon black, a special technology, applied in the field of dyes, can solve the problems of dyeing fastness and poor dyeing performance, and achieve the effects of excellent dyeing performance, increased added value and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides the preparation method of above-mentioned a kind of special pigment carbon black dyeing, comprises the following steps:

[0044] Polyamide resin, polyvinyl alcohol, monomethyl succinate, lignocellulose, plant ash, hemp vine, carbon black, fumed silica, paraffin, sodium citrate, dispersant, color fixing agent, defoamer 1. Add the fragrance agent into the water, mix evenly and adjust the pH value of the solution to 4-5 to obtain the product.

[0045] Here polyamide resin, polyvinyl alcohol, monomethyl succinate, lignocellulose, plant ash, hemp vine, carbon black, fumed silica, paraffin, sodium citrate, dispersant, color fixing agent, defoamer Agent, fresh fragrance agent are all the same as above, no longer repeat them here.

[0046] In the above technical solution, the preparation process is simple, the prepared dye has excellent dyeing performance, the dyed cloth is uniform in color, and is not easy to fade, the dyeing fastness is good...

Embodiment 1

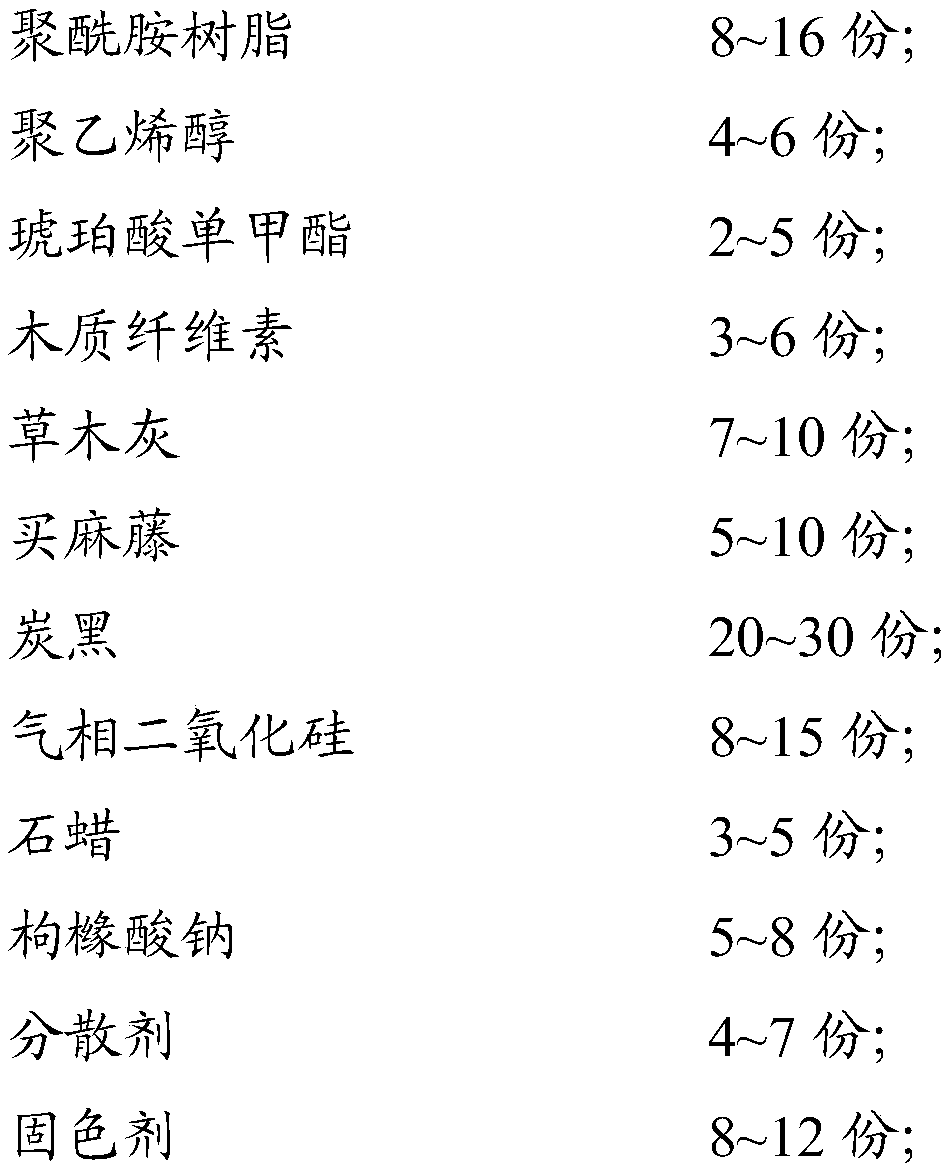

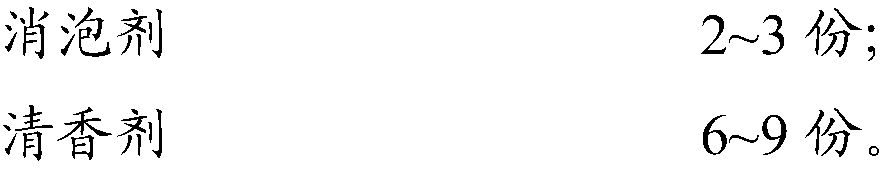

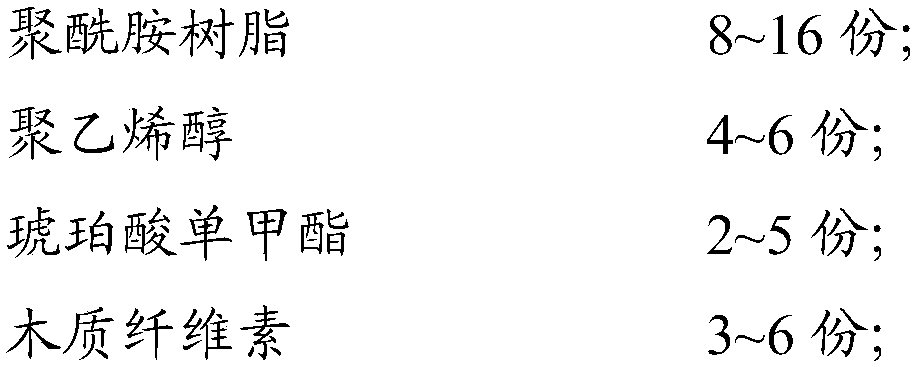

[0049] Special pigment carbon black dyestuff, comprises the raw material of following parts by weight:

[0050] 10 parts of polyamide-6, 4.6 parts of polyvinyl alcohol, 3 parts of monomethyl succinate, 3.5 parts of lignocellulose, 7.5 parts of plant ash, 5 parts of hemp vine, 26 parts of carbon black, 15 parts of fumed silica, 3.5 parts Parts of chlorinated paraffin-52, 6 parts of sodium citrate, 4.5 parts of Tween 80, 8 parts of color fixing agent, 2.4 parts of octanol, 7 parts of fragrance agent;

[0051] The color fixing agent comprises sodium oleoylamino acid, tea polyphenol, sodium polyacrylate, fatty alcohol polyoxyethylene ether sodium sulfate, tung oil anhydride, ethyl acetate and Sodium citrate;

[0052] Fragrance agent includes amino polysaccharide quaternary ammonium salt, activated carbon, aloe extract, sodium dodecylbenzenesulfonate, Rosa roxa extract, Gardenia yellow Color and lavender essential oil;

[0053] The average particle diameter of plant ash, carbon ...

Embodiment 2

[0057] Special pigment carbon black dyestuff, comprises the raw material of following parts by weight:

[0058] 11 parts of nylon-6, 4.3 parts of polyvinyl alcohol, 4 parts of monomethyl succinate, 3 parts of lignocellulose, 8 parts of plant ash, 6 parts of hemp vine, 24 parts of carbon black, 13 parts of fumed silica, 3.8 parts Polyethylene wax, 7 parts of sodium citrate, 6.5 parts of sodium dodecylbenzene sulfonate, 9.5 parts of color fixing agent, 2 parts of polydimethylsiloxane, 8 parts of fragrance agent;

[0059] The color fixing agent comprises sodium oleoylamino acid, tea polyphenol, sodium polyacrylate, fatty alcohol polyoxyethylene ether sodium sulfate, tung oil anhydride, ethyl acetate and Sodium citrate;

[0060] Fragrance agent includes amino polysaccharide quaternary ammonium salt, activated carbon, aloe extract, sodium dodecylbenzenesulfonate, Rosa roxa extract, gardenia yellow Color and lavender essential oil;

[0061] The average particle diameter of plant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com