A kind of positive electrode material of sodium-rich phase sodium-ion battery and its preparation and application

A sodium-ion battery and positive electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult capacity, low conductivity, and poor rate performance, and achieve high capacity, improved conductivity, and high Effect of Magnification Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

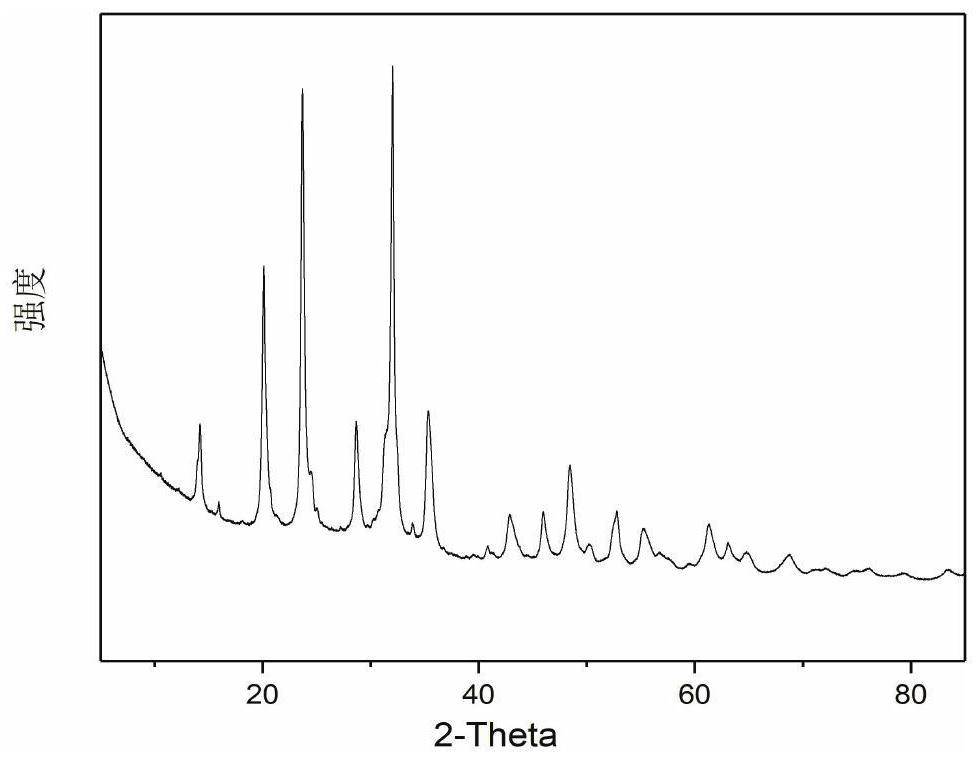

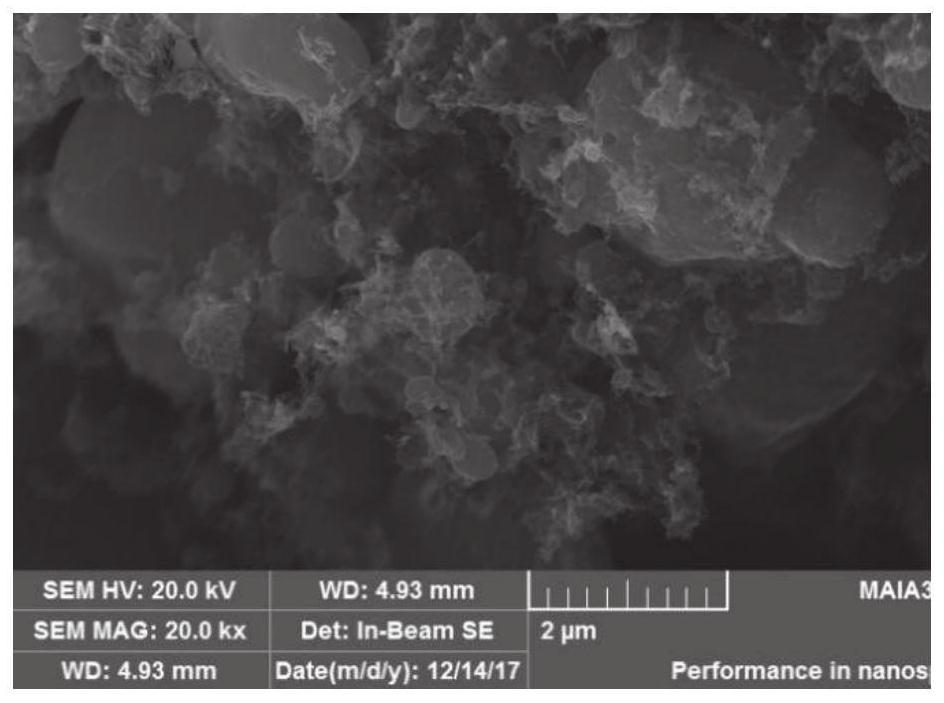

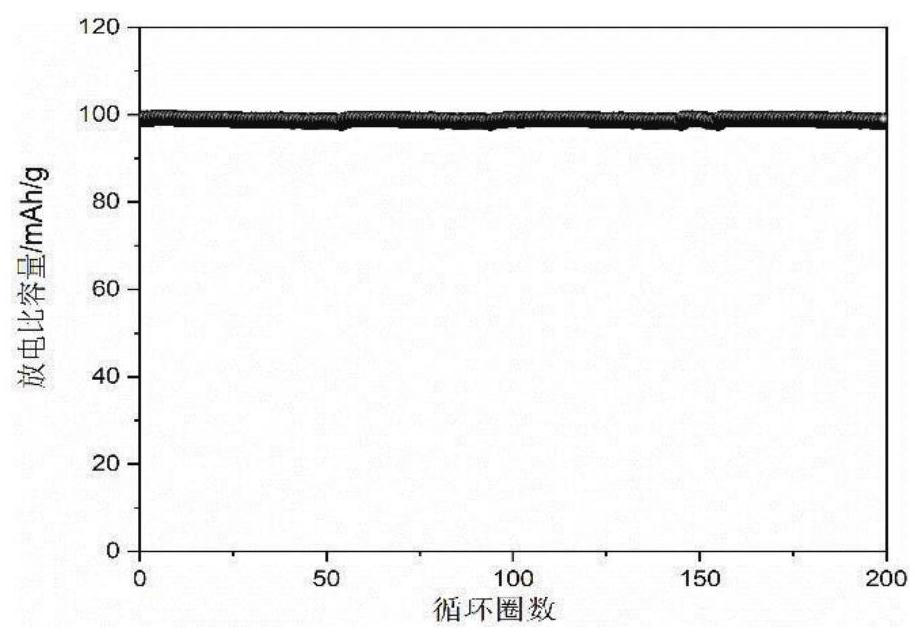

[0062] First, take 36mmol sodium acetate, 10mmol manganese acetate, 8.5mmol titanium dioxide, 30mmol ammonium dihydrogen phosphate, add appropriate amount of absolute ethanol, ball mill at 450rpm with ordinary planetary ball mill for 12h, and calcinate at 650°C for 10h under argon atmosphere to obtain the precursor. The precursor and 10wt% (based on the total mass of the mixed material) CNTs were milled by 10000HZ high-energy vibration ball for 1 hour, and then the mixed material was placed in an argon atmosphere tube furnace and sintered at 650°C for 10 hours. The obtained solid product was for Na 3.6 MnTi 0.85 (PO 4 ) 3 / CNT composite cathode material. The produced Na 3.6 MnTi 0.85 (PO 4 ) 3 / CNT cathode material X-ray diffraction pattern (XRD) see figure 1 . Depend on figure 2 It can be seen that the obtained Na 3.6 MnTi 0.85 (PO 4 ) 3 The particles are irregular, and there are carbon nanotubes in the outer layer of the particles.

[0063] The positive elect...

Embodiment 2

[0065] First, take 42mmol sodium acetate, 10mmol manganese acetate, 0.7mmol titanium dioxide, 30mmol ammonium dihydrogen phosphate, add appropriate amount of absolute ethanol, ball mill at 450rpm with ordinary planetary ball mill for 12h, and calcinate at 650°C for 10h under argon atmosphere to obtain the precursor. The precursor and 10wt% (based on the total mass of the mixed material) CNTs were milled by 10000HZ high-energy vibration ball for 1 hour, and then the mixed material was placed in an argon atmosphere tube furnace and sintered at 650°C for 10 hours. The obtained solid product was for Na 4.2 MnTi 0.7 (PO 4 ) 3 / CNT composite cathode material. The positive electrode material of the sodium ion battery prepared in this example and the sodium sheet are assembled into a button battery, and the discharge specific capacity reaches 82mAh / g after 200 cycles at 0.2C, and the capacity retention rate reaches 91%, indicating that further reduction of titanium content will aff...

Embodiment 3

[0067]First, take 32mmol of sodium acetate, 10mmol of manganese acetate, 0.95mmol of titanium dioxide, and 30mmol of ammonium dihydrogen phosphate, add an appropriate amount of absolute ethanol, ball mill with a common planetary ball mill at 450rpm for 12h, and calcinate at 650°C for 10h under an argon atmosphere to obtain a precursor. The precursor and 10wt% (based on the total mass of the mixed material) CNTs were milled by 10000HZ high-energy vibration ball for 1 hour, and then the mixed material was placed in an argon atmosphere tube furnace and sintered at 650°C for 10 hours. The obtained solid product was for Na 3.2 MnTi 0.95 (PO 4 ) 3 / CNT composite cathode material. The positive electrode material of the sodium ion battery prepared in this example and the sodium sheet were assembled into a button battery, and the discharge specific capacity reached 93mAh / g after 200 cycles at 0.2C, and the capacity retention rate reached 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com