Preparation method and application of multilevel orientation porous superfine electric spinning composite fiber membrane

A composite fiber membrane and orientation technology, applied in the field of biomedical tissue engineering materials, can solve the problems of poor conductivity of graphene oxide, poor solubility and dispersibility of graphene, and toxicity, achieve high mechanical properties and electrical properties, and is conducive to Effects of cell adhesion, high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

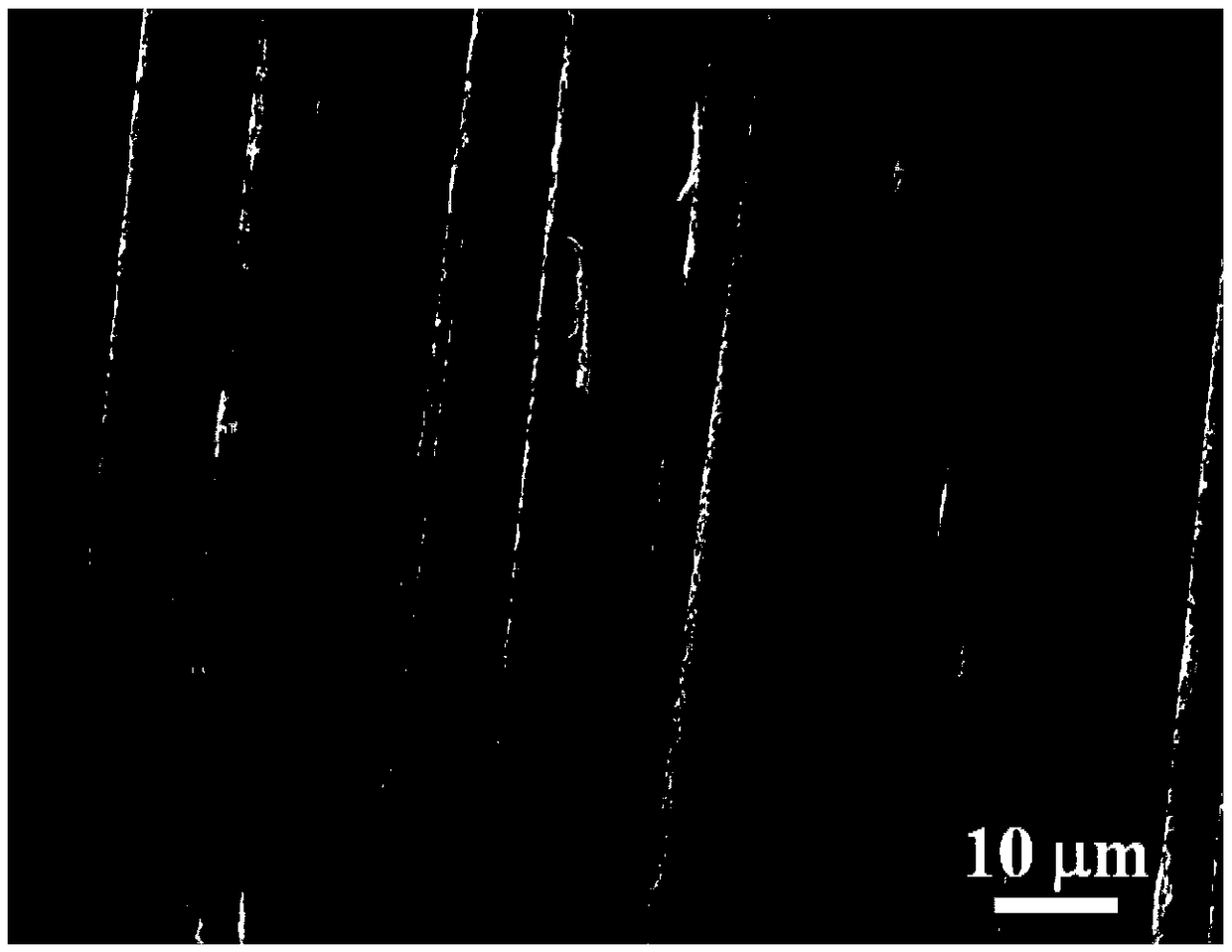

[0040] A method for preparing a multi-level oriented porous ultrafine electrospun composite fiber membrane. The multi-level oriented porous fiber membrane with a mass ratio of polylactic acid and reduced graphene of 1:0.1% is prepared.

[0041] The first step: preparing reduced graphene, comprising the following steps:

[0042] (1) 100mg graphene oxide and 5mg dopamine hydrochloride are added in Tris hydrochloric acid solvent, the concentration of Tris hydrochloric acid is 1.5g / L, pH=8.5, make it fully dissolve and make mixed solution;

[0043] (2) The mixed solution prepared in step (1) is subjected to ice-bath ultrasonication first, the ice-bath temperature is 0°C, the ultrasonic treatment time is 20min, and then stirred and oscillated at a certain stirring temperature, the stirring temperature is 50°C, and the stirring and oscillating The time is 30h;

[0044] (3) The mixed solution treated in step (2) is suction-filtered, placed in a fume hood to air-dry, and polydopamine...

Embodiment 2

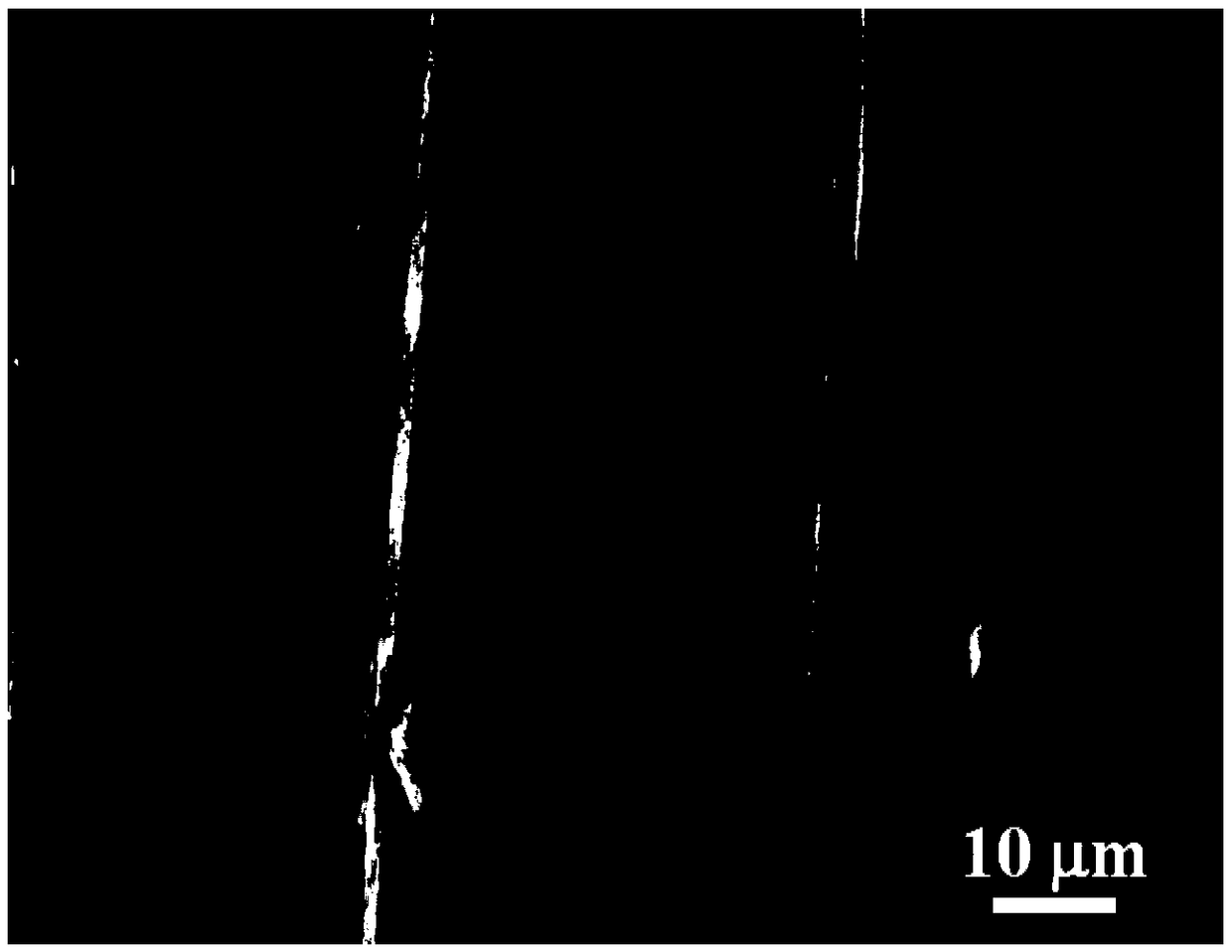

[0051] A method for preparing a multi-level oriented porous ultrafine electrospun composite fiber membrane. The multi-level oriented porous fiber membrane with a mass ratio of polylactic acid and reduced graphene of 1:0.5% is prepared.

[0052] The first step: preparing reduced graphene, comprising the following steps:

[0053] (1) 100mg graphene oxide and 5mg dopamine hydrochloride are added in Tris hydrochloric acid solvent, the concentration of Tris hydrochloric acid is 1.5g / L, pH=8.5, make it fully dissolve and make mixed solution;

[0054] (2) The mixed solution prepared in step (1) is first subjected to ice bath ultrasonication, the ice bath temperature is 2°C, the ultrasonic treatment time is 15min, and then stirred and oscillated at a certain stirring temperature, the stirring temperature is 58°C, and the stirring and oscillating The time is 24h;

[0055] (3) The mixed solution treated in step (2) is suction-filtered, placed in a fume hood to air-dry, and polydopamine...

Embodiment 3

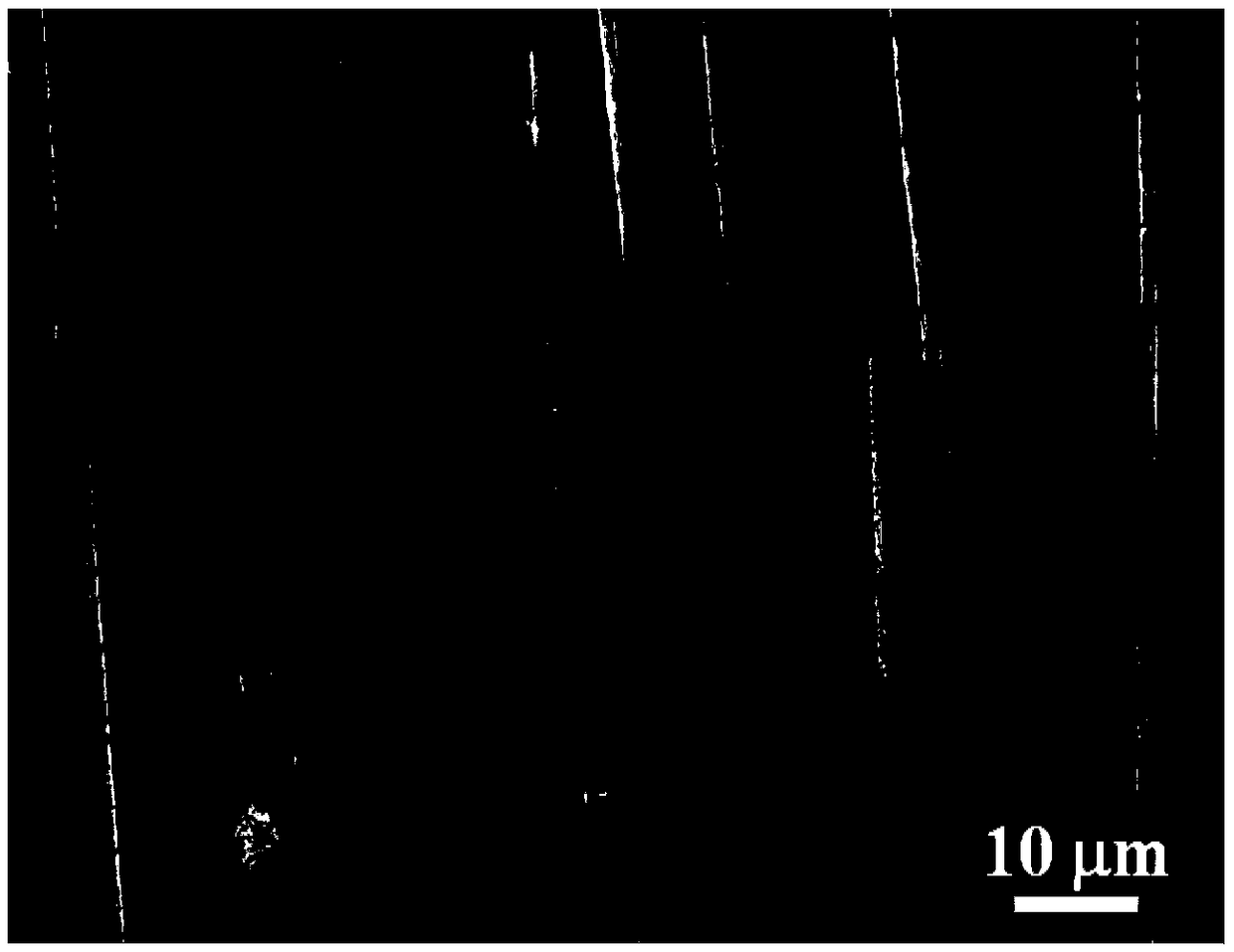

[0062] A method for preparing a multi-level oriented porous ultrafine electrospun composite fiber membrane. The multi-level oriented porous fiber membrane with a mass ratio of polylactic acid and reduced graphene of 1:1% is prepared.

[0063] The first step: preparing reduced graphene, comprising the following steps:

[0064] (1) 100mg graphene oxide and 5mg dopamine hydrochloride are added in Tris hydrochloric acid solvent, the concentration of Tris hydrochloric acid is 1.5g / L, pH=8.5, make it fully dissolve and make mixed solution;

[0065] (2) The mixed solution prepared in step (1) is first subjected to ice bath ultrasonication, the ice bath temperature is 4°C, the ultrasonic treatment time is 10min, and then stirred and oscillated at a certain stirring temperature, the stirring temperature is 70°C, and the stirring and oscillating The time is 20h;

[0066] (3) The mixed solution treated in step (2) is suction-filtered, placed in a fume hood to air-dry, and polydopamine-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Hole length | aaaaa | aaaaa |

| Hole width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com