Oxygen-enriched nano bio-enzyme electrode as well as sensor device, preparation method and application of oxygen-enriched nano bio-enzyme electrode

A sensor device and biological enzyme technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of difficult electrode structure, limited linear range of glucose detection, interference of glucose response signals, etc., and meets the requirements of preparation technology with simple and easy conditions. The effect of mass production, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

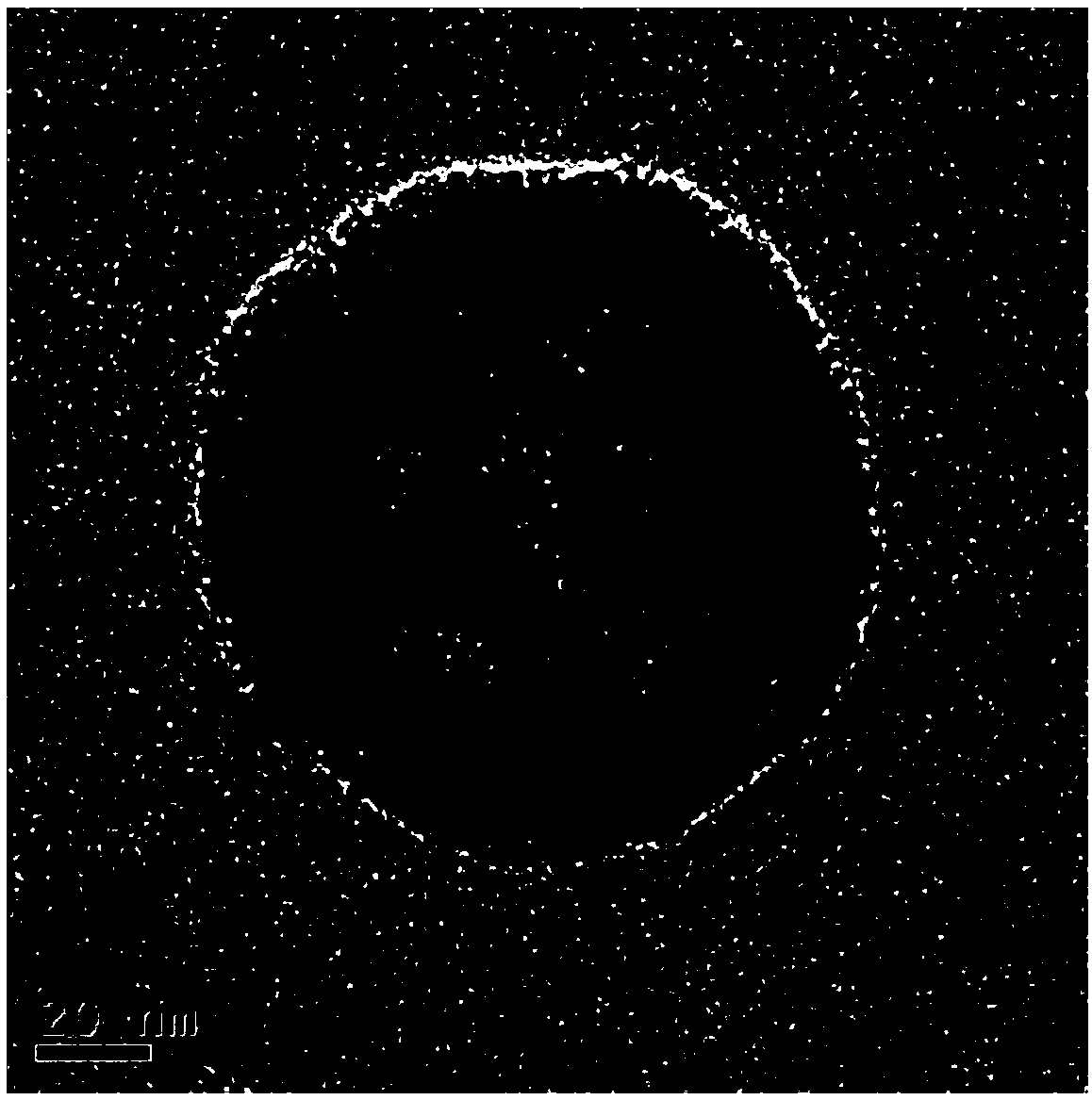

[0106] Hollow mesoporous silica spheres were prepared by the following method:

[0107] (1) 25ml aqueous solution including 100nm polystyrene microspheres 0.2wt%, cetyltrimethylammonium bromide 0.2wt%, sodium hydroxide 0.056wt% and 1,2-bis(triethoxysilyl) Ethane 0.768wt%, stirred and reacted at 80°C for 2 hours, then centrifuged and washed 3 times with water and ethanol to obtain a sample.

[0108] (2) Drop the polystyrene@mesoporous silica balls washed in (1) on the cleaned glass slide, put them into a tube furnace, and calcine for 6 hours with oxygen at 550°C.

[0109] (3) Scrape the hollow mesoporous silica sphere prepared in (2) from the glass slide with a clean blade, add a certain amount of ethanol or deionized water, and make a certain amount of hollow mesoporous silica sphere ethanol or aqueous solution.

[0110] The above slide cleaning method is to use ethanol: acetone: water as a 1:1:1 organic solvent as a cleaning agent, ultrasonic for 15 minutes, and an oven in ...

Embodiment 3

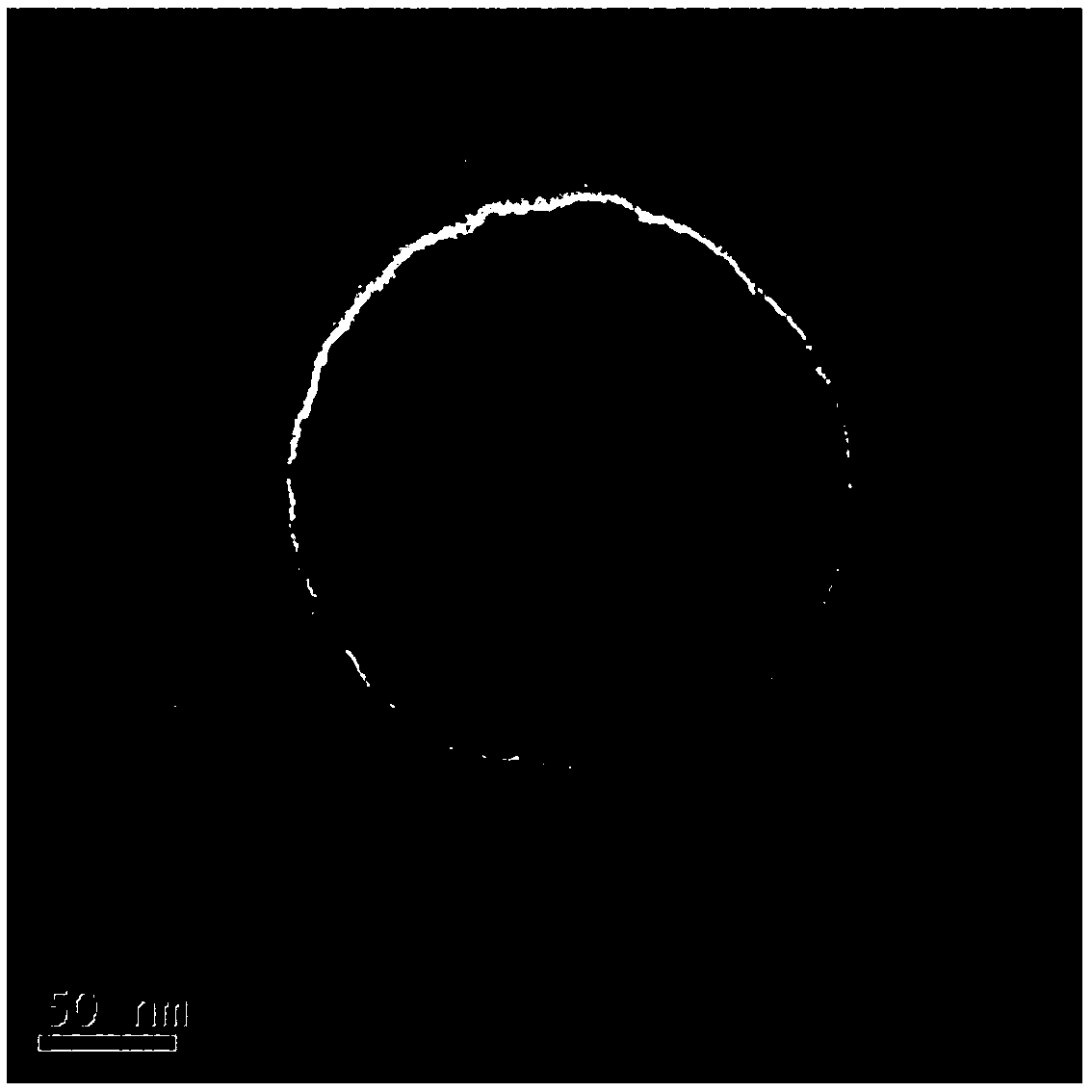

[0119] Hollow mesoporous silica spheres were prepared by the following method:

[0120] (1) 25ml aqueous solution including 100nm polystyrene microspheres 0.2wt%, cetyltrimethylammonium bromide 0.2wt%, sodium hydroxide 0.056wt% and 1,2-bis(triethoxysilyl) Ethane 0.576wt%, stirred and reacted at 80°C for 2 hours, then centrifuged with water and ethanol for 3 times to obtain a sample.

[0121] (2) Drop the polystyrene@mesoporous silica balls washed in (1) on the cleaned glass slide, put them into a tube furnace, and calcine for 6 hours with oxygen at 550°C.

[0122] (3) Scrape the hollow mesoporous silica sphere prepared in (2) from the glass slide with a clean blade, add a certain amount of ethanol or deionized water, and make a certain amount of hollow mesoporous silica sphere ethanol or aqueous solution.

[0123] The above slide cleaning method is to use ethanol: acetone: water as a 1:1:1 organic solvent as a cleaning agent, ultrasonic for 15 minutes, and an oven in an oven...

Embodiment 4

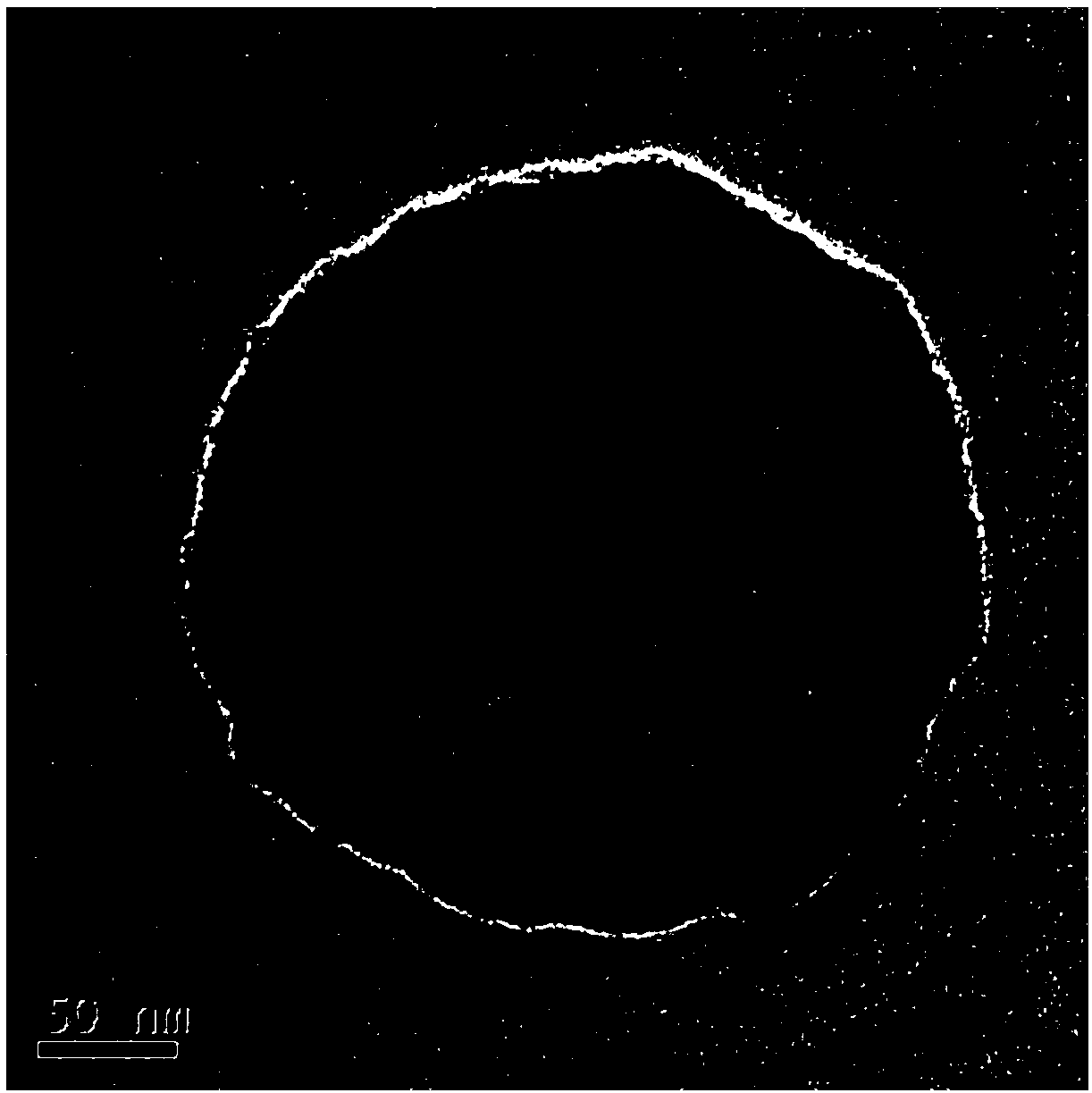

[0132] Prepare hollow alumina spheres by the following method:

[0133] (1) Dissolve 0.6303g of ammonium formate in 50ml of deionized water, and adjust the pH to 4.4 with formic acid. 3 ml (2.5 wt %) of an aqueous solution of 100 nm polystyrene microspheres and 0.351 g of aluminum sulfate sonicated for 15 minutes were added. After reacting at 70°C for two hours, centrifuge and wash with water and ethanol.

[0134] (2) Drop the polystyrene microspheres@alumina balls washed in (1) on the cleaned glass slide, put them into a tube furnace, and calcinate at 550°C for 2 hours with oxygen.

[0135] (3) Scrape the hollow alumina ball prepared in (2) from the glass slide with a clean blade, add a certain amount of ethanol or deionized water, and make a certain amount of ethanol or aqueous solution of the hollow alumina ball.

[0136] The above slide cleaning method is to use ethanol: acetone: water as a 1:1:1 organic solvent as a cleaning agent, ultrasonic for 15 minutes, and an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com