Preparation method of graphene-based organic solar cell interface material

A technology for solar cells and interface materials, which is applied in the field of preparation of interface materials for graphene-based organic solar cells, can solve the problems of uniform thin films, cannot be coated and formed, and affects photoelectric conversion efficiency, and achieves the effect of avoiding agglomeration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

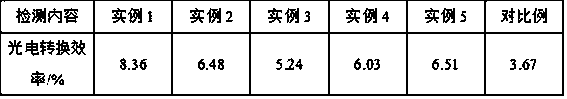

Examples

example 1

[0024] According to the mass ratio of 1:10, graphene oxide and isocyanate were mixed and poured into No. 1 three-necked flask. Under the condition of ultrasonic frequency of 60 kHz, after ultrasonic dispersion for 60 minutes, the No. 1 three-necked flask was moved into a digital speed measuring constant temperature magnetic stirrer. At a temperature of 70°C and a rotation speed of 600r / min, stir and react at a constant temperature for 3 hours, filter to obtain No. 1 filter cake, and then vacuum-dry the obtained No. 1 filter cake to obtain isocyanate-modified graphene oxide; the isocyanate-modified graphite oxide The dimethyl formamide solution of alkene and sodium azide is mixed according to the mass ratio of 1:8 and poured into No. 2 three-neck flask. Under the condition of ultrasonic frequency of 60kHz, after ultrasonic dispersion for 60min, move the No. 2 flask into the digital display speed measurement In a constant temperature magnetic stirrer, at a temperature of 75°C and...

example 2

[0026] Mix the dimethylformamide solution of graphene oxide and sodium azide at a mass ratio of 1:8 and pour it into a No. 2 three-necked flask. In a magnetic stirrer with digital speed measurement and constant temperature, at a temperature of 75°C and a rotational speed of 600r / min, stir and react at a constant temperature for 3 hours, then filter to obtain No. 2 filter cake, and use dimethylformamide After washing 5 times, vacuum-dry to obtain sodium azide-modified graphene oxide; mix sodium azide-modified graphene oxide and tetrahydrofuran at a mass ratio of 1:12 and pour it into a No. Under certain conditions, after ultrasonic dispersion for 50 min, the No. 3 three-neck flask was moved into a digital display speed measuring constant temperature magnetic stirrer, and lithium aluminum hydride, which was 0.5 times the mass of sodium azide-modified graphene oxide, was added to the No. 3 three-necked flask. At 85°C and a rotation speed of 800r / min, stir and react at a constant ...

example 3

[0028] According to the mass ratio of 1:10, graphene oxide and isocyanate were mixed and poured into No. 1 three-necked flask. Under the condition of ultrasonic frequency of 60 kHz, after ultrasonic dispersion for 60 minutes, the No. 1 three-necked flask was moved into a digital speed measuring constant temperature magnetic stirrer. At a temperature of 70°C and a rotation speed of 600r / min, stir and react at a constant temperature for 3 hours, then filter to obtain No. 1 filter cake, and then vacuum-dry the obtained No. 1 filter cake to obtain isocyanate-modified graphene oxide; Graphene and concentrated hydrochloric acid with a mass fraction of 35% were mixed according to a mass ratio of 1:5 and poured into a No. 4 three-neck flask with a reflux condenser, heated and refluxed for 5 hours, and then filtered to obtain a No. 4 filter cake, and deionized water Wash No. 4 filter cake 5 times, then vacuum-dry the No. 4 filter cake after washing to obtain hydrolyzed reduced graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com