Preparation method and applications of hyperbranched zwitterion modified polyvinylidene fluoride oil-water emulsion separation membrane

A polyvinylidene fluoride oil and polyvinylidene fluoride membrane technology is applied in the field of preparation of a new type of hyperbranched zwitterion-modified polyvinylidene fluoride oil-water emulsion separation membrane, and can solve the problems of shortening the service life of the membrane, attenuation of membrane flux, and impact on The development and application of separation membrane materials have achieved the effect of controllable structure, simple equipment, stable and continuous anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

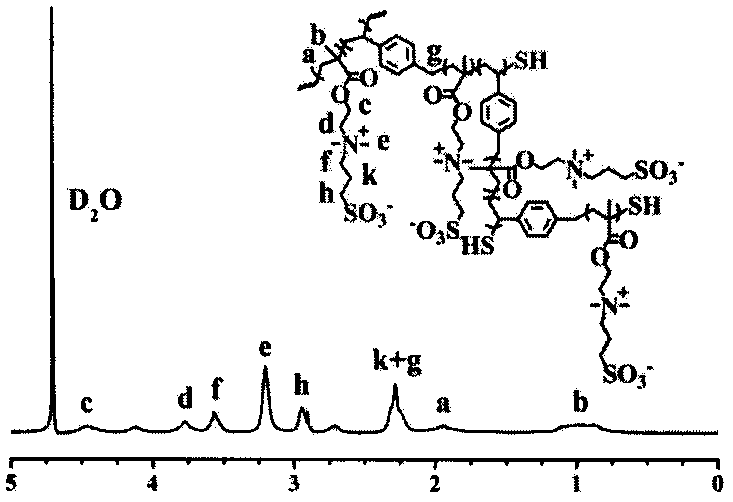

[0034] (1) Dissolve dimethylaminoethyl methacrylate, trithiocarbonate and azobisisobutyronitrile in toluene, stir magnetically at 70°C for 24 hours, and obtain uniform, yellow Clear solution. After the reaction was completed, the yellow transparent solution was rotary evaporated at 40° C. to remove part of the toluene. The solution after rotary evaporation was added dropwise to ice n-hexane / ethyl acetate mixed solution to obtain a yellow precipitate; the precipitate was soaked in n-hexane solution for 30 min. The obtained yellow precipitate was vacuum-dried to obtain hyperbranched polydimethylaminoethyl methacrylate;

[0035] (2) A certain amount of hyperbranched polydimethylaminoethyl methacrylate in step (2) is dissolved in methanol, stirred evenly at room temperature, after it dissolves completely, add excess 1,3-propanesulfonic acid Lactone, under the protection of an inert gas, heated and reacted at 60°C for 48 hours to obtain a hyperbranched zwitterionic polymer;

[0...

Embodiment 2

[0042] (1) The preparation method of thiol-terminated hyperbranched zwitterionic polymer is the same as in Example 1;

[0043] (2) The preparation method of dopamine-modified polyvinylidene fluoride film is the same as in Example 1;

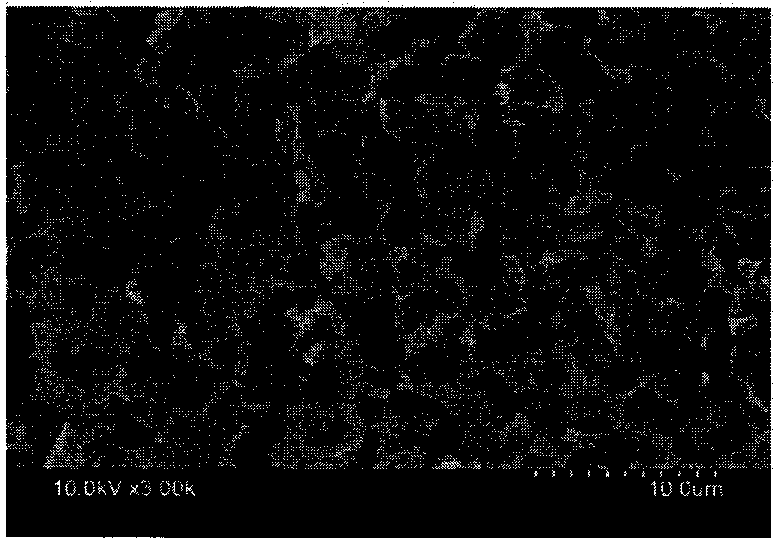

[0044] (3) Soak the above-mentioned dopamine-modified polyvinylidene fluoride membrane in a Tris-HCl buffer solution with pH=8.5 for vacuum deoxygenation; add 0.025 g of thiol-terminated hyperbranched zwitterionic polymer, wait for it to dissolve, and add 35 μl of triethylamine ;

[0045] (4) The above reaction was placed in a constant temperature oscillator for 4 hours, and the reaction was continued for 8 hours in the atmosphere. After the reaction is finished, rinse with distilled water and dry to obtain a polyvinylidene fluoride oil-water emulsion separation membrane with good hydrophilicity and underwater super-oleophobicity.

Embodiment 3

[0047] (1) The preparation method of thiol-terminated hyperbranched zwitterionic polymer is the same as in Example 1;

[0048] (2) The preparation method of dopamine-modified polyvinylidene fluoride film is the same as in Example 1;

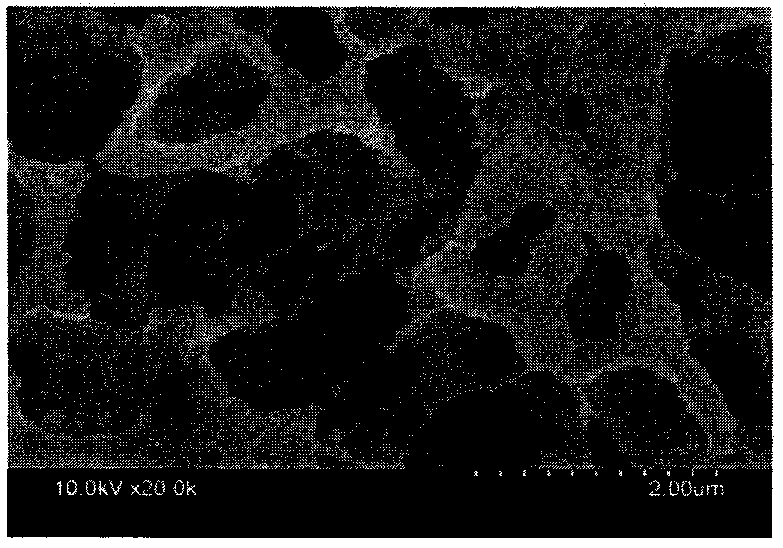

[0049] (3) Soak the above-mentioned dopamine-modified polyvinylidene fluoride membrane in a Tris-HCl buffer solution with pH=8.5 for vacuum deoxygenation; add 0.1 g of thiol-terminated hyperbranched zwitterionic polymer, wait for it to dissolve, and add 35 μl of triethylamine ;

[0050] (4) Put the above reaction in a constant temperature oscillator to react for 4 hours, and continue to react for 8 hours in the air; after the reaction is completed, rinse with distilled water and dry to obtain a super-hydrophilic polyvinylidene fluoride oil-water emulsion separation membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com