Photocatalytic composite material with p-n heterojunction, and preparation method and application thereof

A composite material and photocatalytic technology, which is applied in the field of photocatalytic composite materials and their preparation, and can solve the problems of large band gap energy and limited application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a photocatalytic composite material with a p-n heterojunction, comprising the following steps:

[0031] (1) Sodium bismuthate is mixed with water for hydrothermal reaction to obtain m-Bi 2 o 4 ;

[0032] (2) m-Bi obtained by the step (1) 2 o 4 Dispersed in dispersant to get m-Bi 2 o 4 Dispersions;

[0033] (3) under the condition that the pH value is 1~3, the m-Bi obtained in the step (2) 2 o 4 The dispersion liquid is mixed with a chlorine source and then ultrasonically treated to obtain a photocatalytic composite material with a p-n heterojunction.

[0034] In the present invention, sodium bismuthate is mixed with water for hydrothermal reaction to obtain m-Bi 2 o 4 . In the present invention, the volume ratio of the mass of sodium bismuthate to water is preferably 1-3g:30-90mL, more preferably 2g:60mL.

[0035] The present invention has no special limitation on the mixing method, and a mixing method well known t...

Embodiment 1

[0056] Weigh 1g of sodium bismuthate and disperse it in 30mL of pure water, stir at room temperature for 0.5h, then pour it into a reaction kettle for hydrothermal reaction at 130°C for 16h, cool to room temperature naturally, filter, wash, and dry at 70°C for 10h to obtain m-Bi 2 o 4 .

[0057] Weigh 0.482g of m-Bi 2 o 4 Disperse in 10 mL of absolute ethanol, drop into 1 mL of 1M HCl solution drop by drop, stir magnetically for 3 hours at room temperature, ultrasonic for 1 hour, wash with pure water 5 times, and dry at 50°C for 16 hours to obtain a p-n heterojunction Photocatalytic composites.

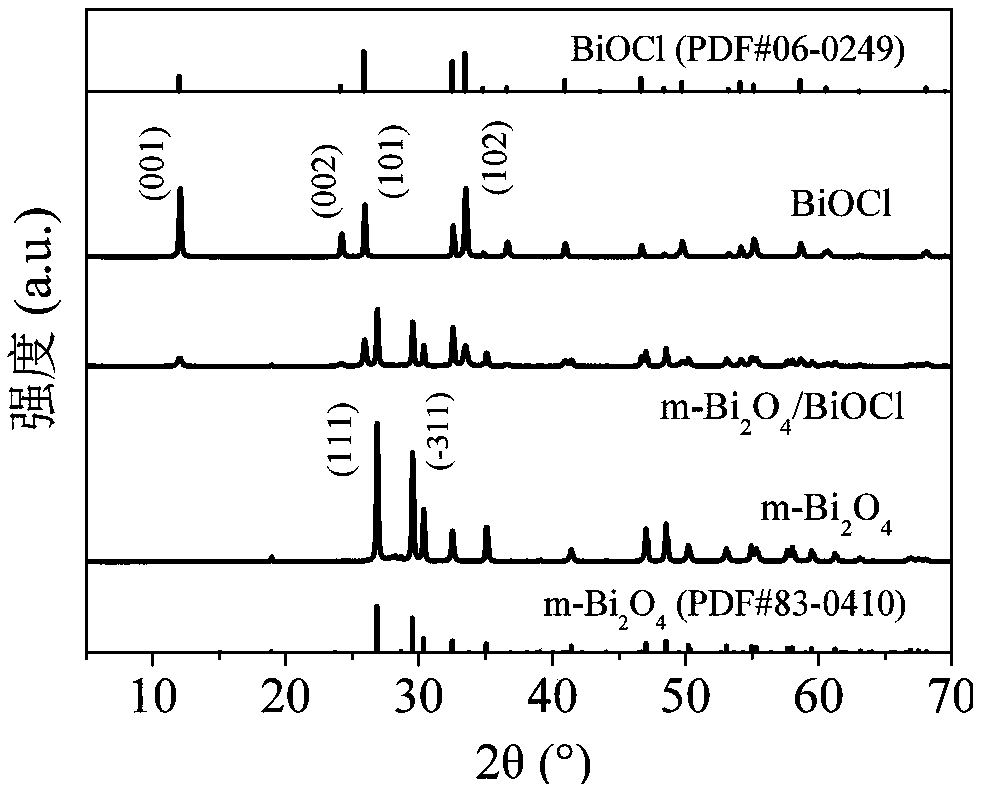

[0058] figure 1 as a single catalyst m-Bi 2 o 4 , BiOCl and the photocatalytic composite material m-Bi that embodiment 1 makes 2 o 4 XRD pattern of / BiOCl. Such as figure 1 As shown, monomers and complexes correspond to the diffraction peaks of standard cards, indicating that the materials were successfully synthesized.

[0059] figure 2 as a single catalyst m-Bi 2 o 4...

Embodiment 2

[0077] Weigh 2g of sodium bismuthate and disperse it in 60mL of pure water, stir at room temperature for 1h, then pour it into a reaction kettle for hydrothermal reaction at 160°C for 14h, cool to room temperature naturally, filter, wash, and dry at 60°C for 15h to obtain m -Bi 2 o 4 .

[0078] Weigh 0.964g of m-Bi 2 o 4 Disperse in 20 mL of pure water, add 0.116 g of sodium chloride, and add dilute nitric acid to adjust pH=1. Stir magnetically for 3.5 hours at room temperature and sonicate for 1.5 hours. After washing with pure water for 4 times, drying at 60°C for 12 hours, a photocatalytic composite material with p-n heterojunction was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com