A kind of PPU glue and the production technology that utilizes this Ppu glue to prepare dipped gloves

A preparation process and water-based technology are applied in the field of PPU glue and the production technology field of using the PPU glue to prepare dipped gloves, which can solve the problems of user allergies, human injury, insufficient use time, etc., and achieve the improvement of production flexibility and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

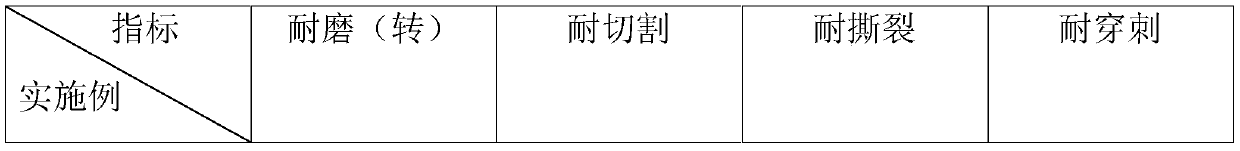

Examples

Embodiment 1

[0083] By weight, PPU glue components:

[0084] 40 parts of water-based PU emulsion, 30 parts of water-based polyurea emulsion, 30 parts of water-based PU adhesive, 1 part of black slurry, 2 parts of foaming agent, 1 part of thickener, and 0.5 part of leveling agent.

[0085] The preparation process of water-based PU emulsion is as follows: 100 parts of polyethylene adipate with a molecular weight of 2000, 6 parts of dimethylol propionic acid, 3 parts of 1,4 butanediol, after vacuum dehydration, add 0.3 parts of stannous octoate After stirring evenly, add 25 parts of toluene diisocyanate, heat to 80°C under stirring, and keep it warm for 1-2 hours, then add 50 parts of acetone, continue the reaction for 2-4 hours, and analyze the NCO% content by di-n-butylamine back titration method to reach After the theoretical value, cool down to 50-60°C, add 4.6 parts of triethylamine for neutralization for 15 minutes, then add 205 parts of deionized water while stirring, add 1.2 parts of ...

Embodiment 2

[0096] By weight, PPU glue components:

[0097] 60 parts of water-based PU emulsion, 20 parts of water-based polyurea emulsion, 20 parts of water-based PU adhesive, 1 part of white pulp, 2 parts of foaming agent, 1 part of thickener, and 0.5 parts of leveling agent.

[0098] The preparation process of water-based PU emulsion is as follows: 100 parts of polyethylene adipate with a molecular weight of 2000, 6 parts of dimethylol propionic acid, 3 parts of 1,4 butanediol, after vacuum dehydration, add 0.3 parts of stannous octoate After stirring evenly, add 25 parts of toluene diisocyanate, heat to 80°C under stirring, and keep it warm for 1-2 hours, then add 50 parts of acetone, continue the reaction for 2-4 hours, and analyze the NCO% content by di-n-butylamine back titration method to reach After the theoretical value, cool down to 50-60°C, add 4.6 parts of triethylamine for neutralization for 15 minutes, then add 205 parts of deionized water while stirring, add 1.2 parts of e...

Embodiment 3

[0110] By weight, PPU glue components:

[0111] 80 parts of water-based PU emulsion, 10 parts of water-based polyurea emulsion, 10 parts of water-based PU adhesive, 1 part of black pulp, 2 parts of foaming agent, 1 part of thickener, and 0.5 parts of leveling agent.

[0112] The preparation process of water-based PU emulsion is as follows: 110 parts of polytetrahydrofuran ether glycol with a molecular weight of 2000, 6 parts of dimethylol propionic acid, 3 parts of 1,4 butanediol, after vacuum dehydration, add 0.3 parts of stannous octoate and stir evenly , add 25 parts of hexamethylene diisocyanate, heat to 90°C under stirring and keep it warm for 1 to 2 hours, then add 50 parts of acetone, continue to react for 2 to 4 hours, and analyze the NCO% content by di-n-butylamine back titration method to reach After the theoretical value, cool down to 50-60°C, add 4.6 parts of triethylamine for neutralization for 15 minutes, then add 220 parts of deionized water while stirring, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com